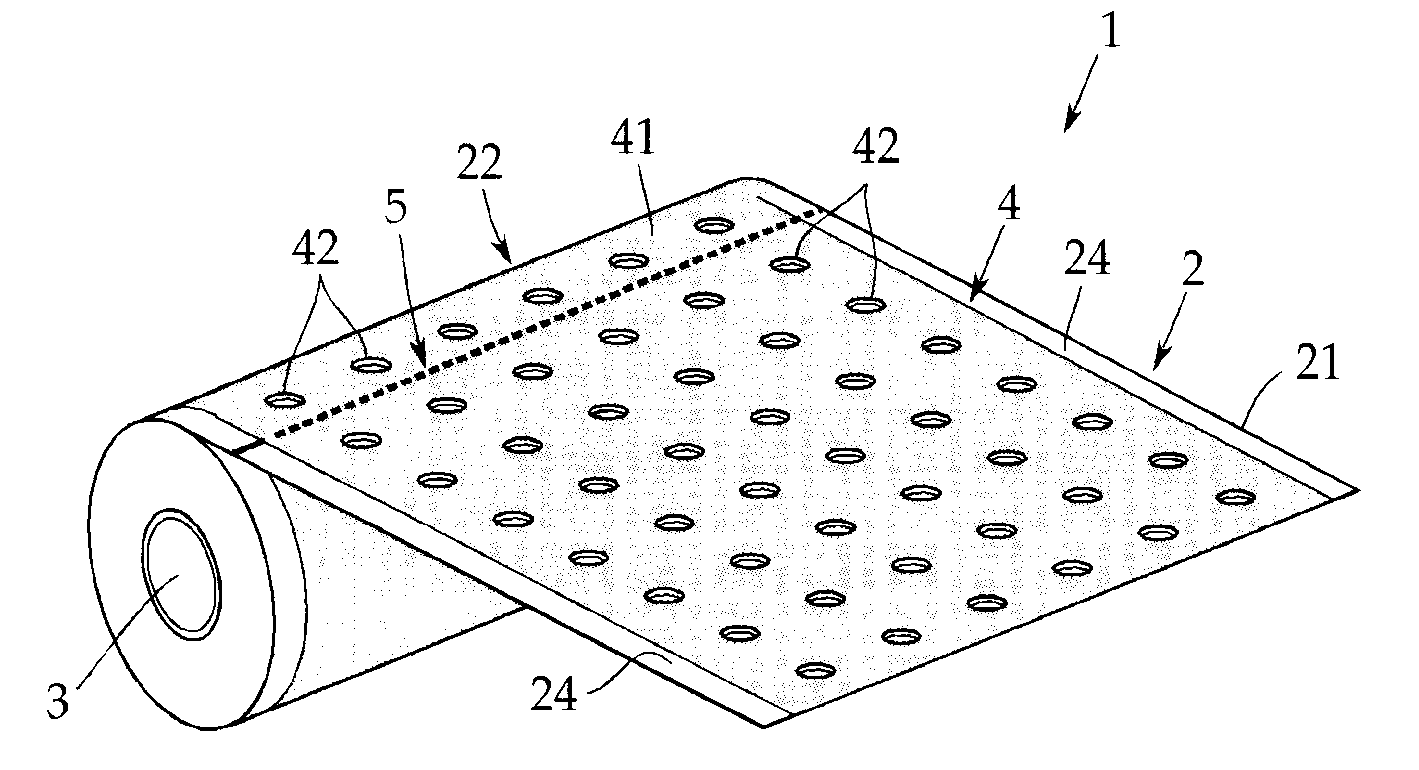

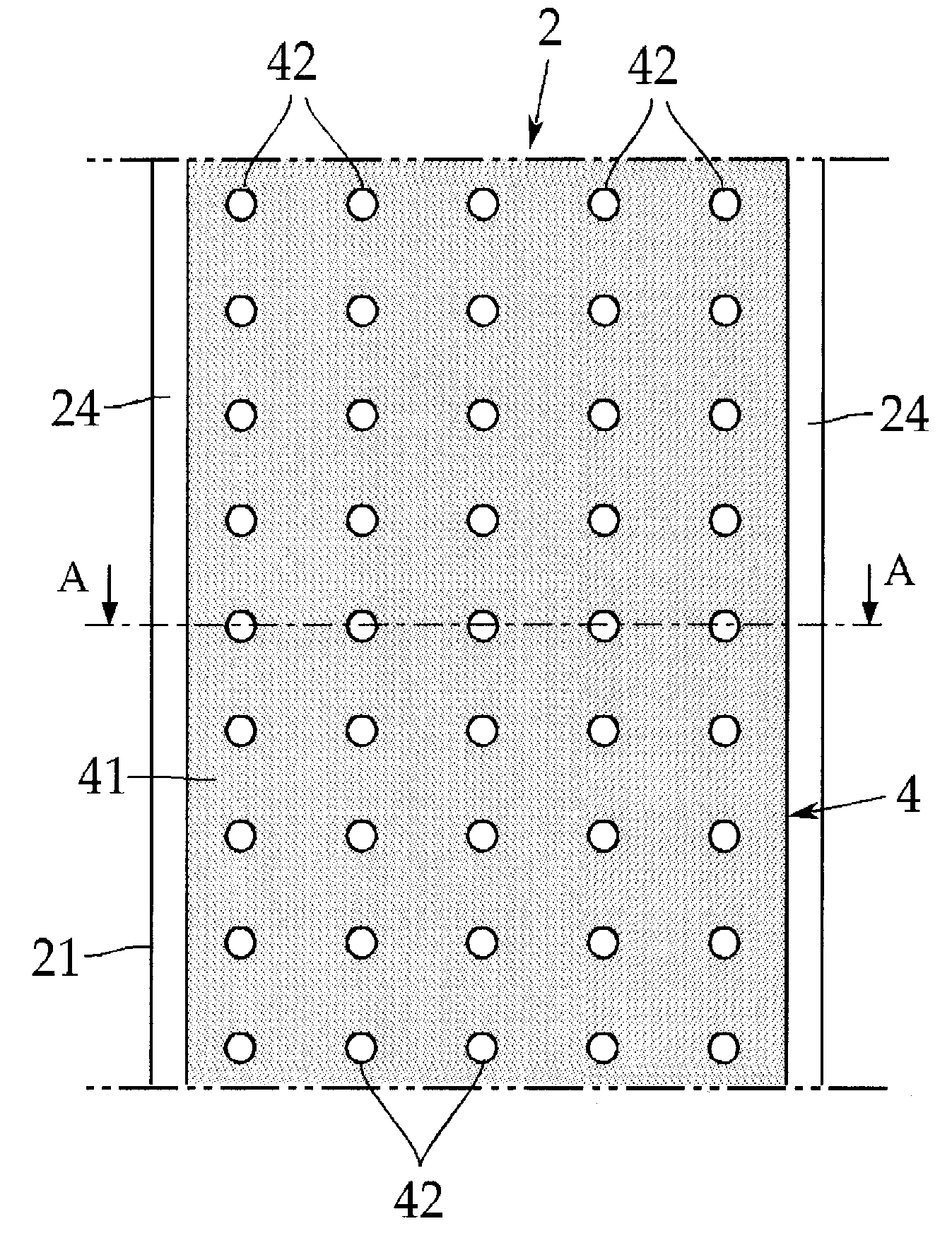

Adhesive tape roll and method for manufacturing same

A technology of adhesive tape roller and adhesive tape, which is applied in the direction of adhesives, film/sheet adhesives, cleaning equipment, etc., which can solve the problem of reduced ability to capture dirt, hard adhesive tape, and inability to follow the ground softly, etc. problems, to achieve the effect of reducing the amount, easy to roll, and saving printing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

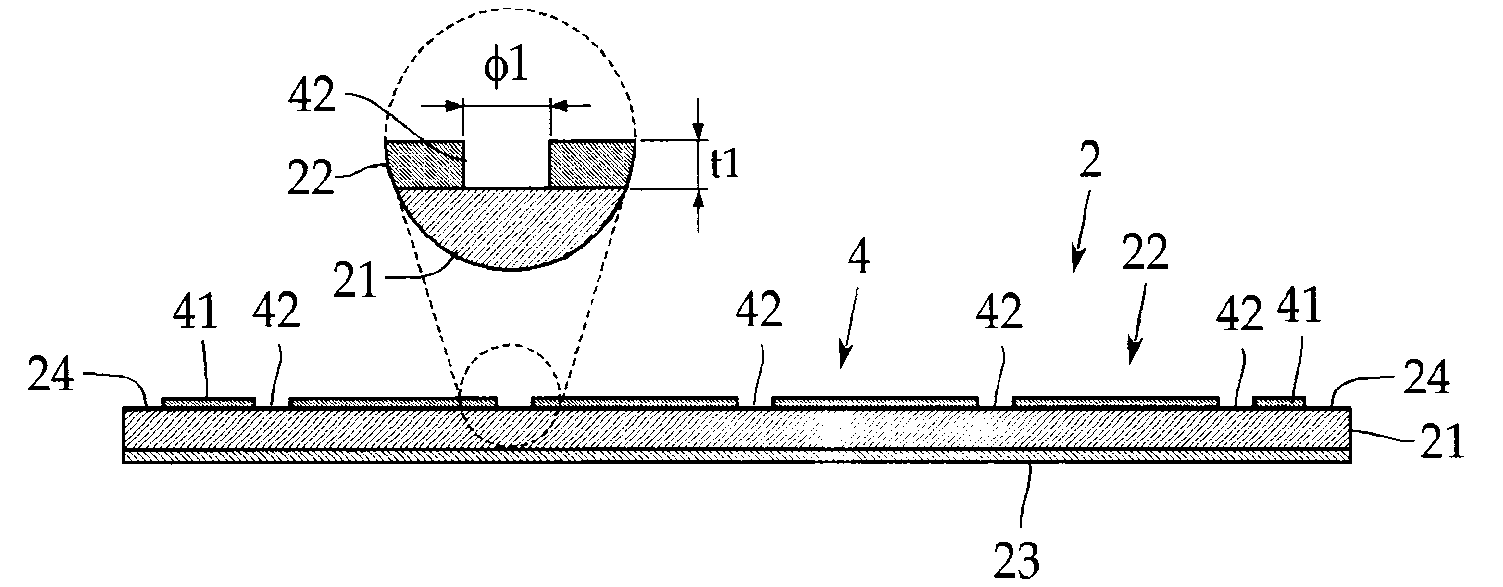

[0076] Specific examples are given below as examples to illustrate the relationship between the thickness and the area ratio of the adhesive layer 4 of the adhesive tape. First prepare the following adhesive tape: On one side of a paper substrate (width 150 mm), the layer thickness of the adhesive layer 4 is changed in 5 μm steps in the range of 10-35 μm, and the coated The area was changed in the range of 40-100%, and the rotational resistance value at this time was measured according to the measurement method shown below.

[0077] The rotational resistance value was measured using a dedicated measuring device. like Figure 9 As shown, the frame with the adhesive tape roller 1 installed on the top and the resistance meter R integrally installed on the other end moves horizontally from the starting point A to the end point B (800 mm) at 725 mm / s through a driving device not shown in the figure. At this time, the load generated between the surface to be cleaned (carpet C) is ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com