Method for manufacturing foil by composite oxidation film at low pressure

A technology of composite oxide film and manufacturing method, which is applied in anodizing, electrolytic capacitors, electrical components, etc., can solve the problems of oxide film thickness, inability of phosphate radicals to diffuse into, inability to have both electrostatic capacity and hydration resistance, etc. The effect of hydration resistance

Inactive Publication Date: 2010-11-10

DONGGUAN HEC CONDENSER CO LTD

View PDF0 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

However, chemical post-treatment also brings defects that cannot be ignored while improving product performance.

First of all, when the formation voltage reaches a high value, because the pores of the low-pressure formation foil are non-straight sponge-like pores, the oxide film formed on the surface is thicker, and the phosphate radical cannot diffuse into the pores during chemical post-treatment. It is difficult to cover the passivation treatment comprehensively and thoroughly; secondly, due to the low efficiency of chemical post-treatment, in order to achieve better results, the concentration and temperature are often increased, which will lose part of the electrostatic capacity, making the electrostatic capacity and hydration resistance unsatisfactory. have both

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

Embodiment 2

Embodiment 3

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

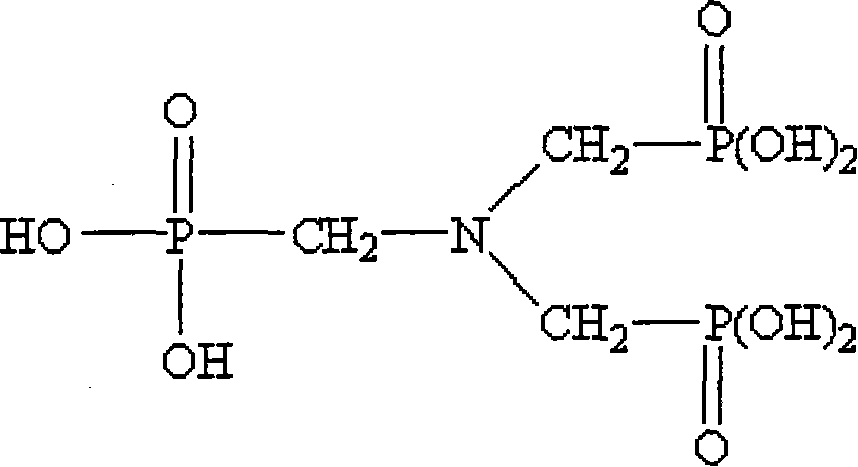

The invention relates to the technical field of formed foils, in particular to a method for manufacturing a composite oxide film low-voltage formed foil. The method is as follows: firstly, a formed foil is treated by sodium silicate, and an aluminum silicate film is generated on the surface of the formed foil, is a good hydration resistant film and can improve the hydration resistance of the formed foil; and secondly, the formed foil is formed in a mixture of ATMP and ammonium adipate, and a hydrous aluminum phosphate film with good water resistance is generated. The aluminum silicate film and the hydrous aluminum phosphate film can effectively prevent reaction of an alumina film and water, improve the hydration resistance of the composite oxide film low-voltage formed foil, and prolong the service life of a capacitor.

Description

A kind of manufacturing method of composite oxide film low-pressure forming foil Technical field: The invention relates to the technical field of formed foils, in particular to a method for manufacturing composite oxide film low-pressure formed foils. Background technique: Electrolytic capacitors are widely used in many related industries such as electronics. The advancement of science and technology and the development of industry have put forward higher requirements for electrolytic capacitors in terms of power frequency, low impedance, and long life. With the development of the electronic industry, electronic products are becoming more and more miniaturized and portable. Therefore, various electronic components tend to develop in the direction of miniaturization, and capacitors are no exception. The volume of aluminum electrolytic capacitors is mainly restricted by the electrostatic capacity of the anode foil (that is, the formed foil). The higher the capacitance of ...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): C25D11/04H01G9/055

Inventor 李道重严志强

Owner DONGGUAN HEC CONDENSER CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com