Method and driving assembly for operating a weaving machine

A technology for driving devices and looms, which is applied in looms, textiles, papermaking, textiles, etc., can solve the problems of increasing the cost of driving devices, and achieve the effect of favorable cost and small structural size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

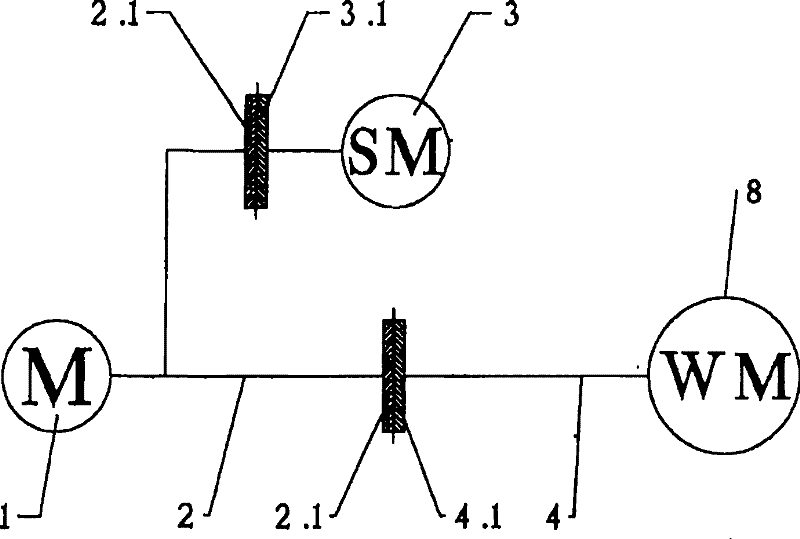

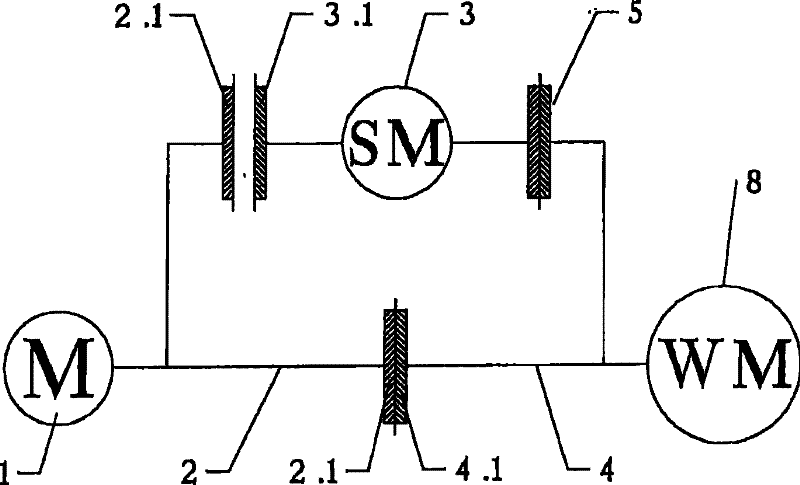

[0056] exist figure 1 The drive shown schematically in FIG. 1 shows a main motor 1 with its rotor shaft 2 and two clutch devices 2.1 secured to the rotor shaft in a non-rotatable manner. A clutch device 2.1 is switchably connected to a first output element 3.1, which is connected to the additional flywheel mass 3 in a non-rotatable manner.

[0057] The other clutch device 2.1 is shiftably connected to a second output element 4.1, which is connected to the main drive shaft 4 in a non-rotatable manner. The main drive shaft 4 drives the individual functional components of the weaving machine 8, such as, for example, weft insertion elements, shed forming devices and reeds.

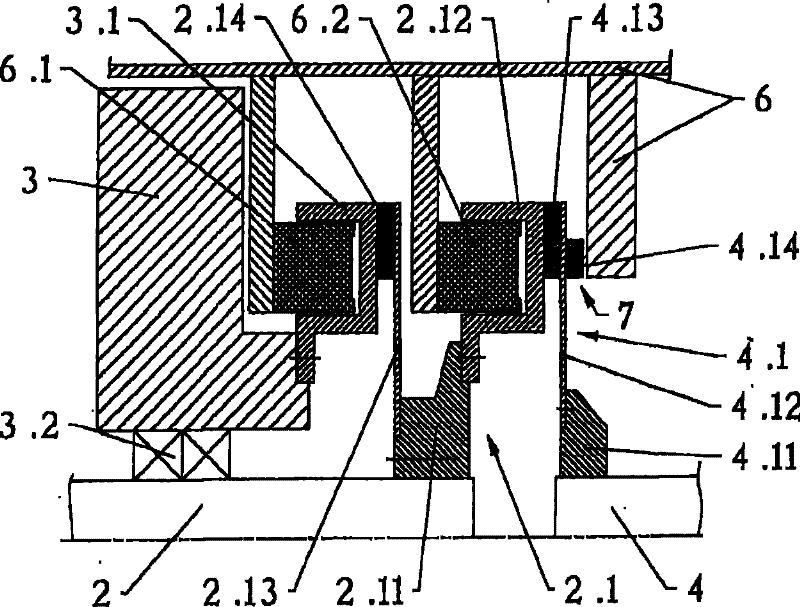

[0058] figure 2 The drive shown shows the rotor shaft 2 of the main motor 1 (not shown) and a clutch device 2 . The clutch device 2.1 comprises a clutch hub 2.11, a first clutch disc 2.12 rigidly connected thereto, and a second diaphragm spring 2.13 with a friction lining 2.14, which is connected to the cl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com