Non-contact type actuator

A non-contact actuator technology, applied in the direction of generator/motor, electrostatic generator/motor, electrical components, etc., can solve problems such as large current consumption, high driving voltage, and component wear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The structure, characteristics and effects of the present invention will be described in detail by citing the following embodiments in conjunction with the accompanying drawings.

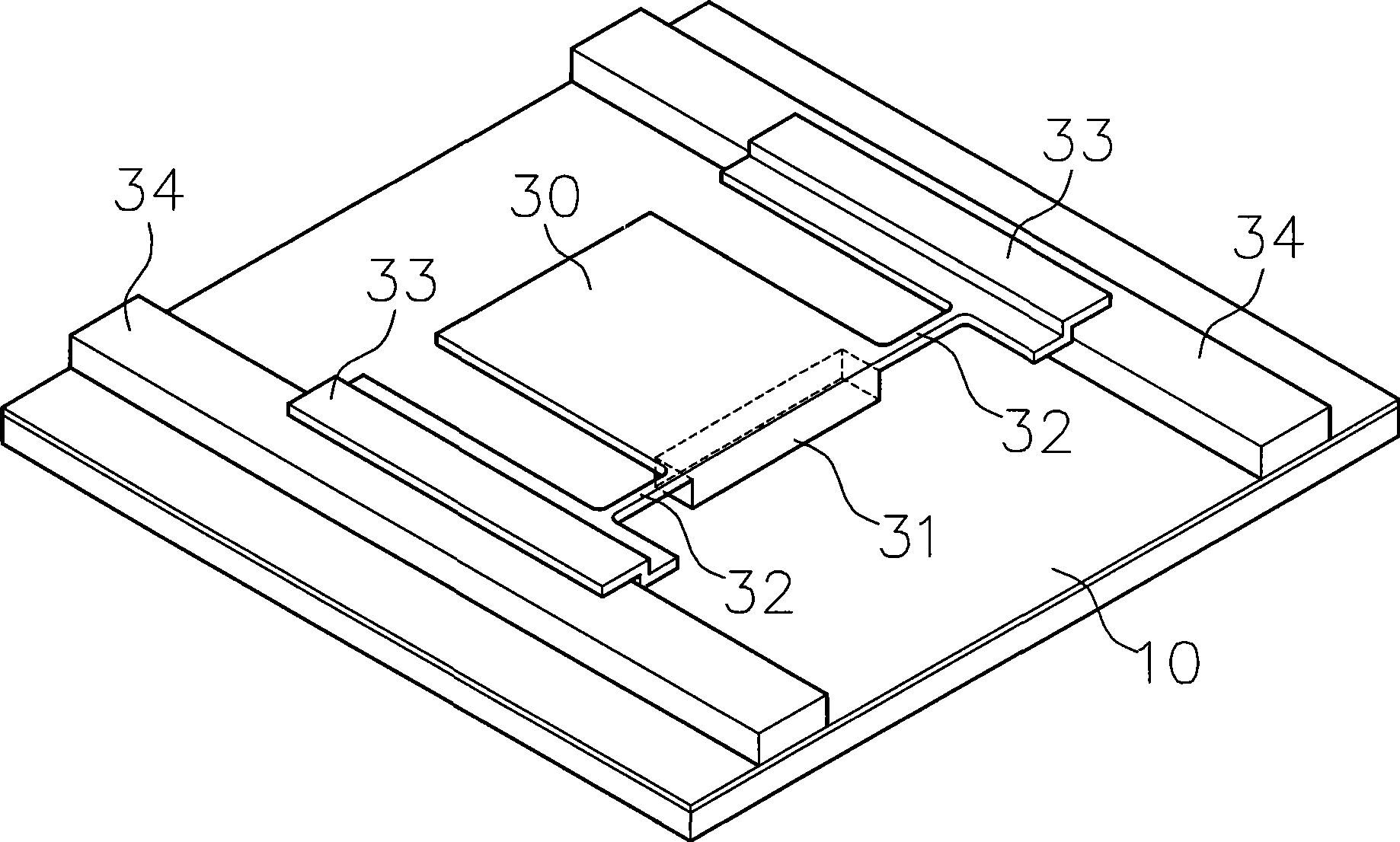

[0022] like figure 2 As shown, the actuator is located on a base plate 10 , which includes a flat plate 30 , a bushing 31 , at least two support beams 32 , at least two sliding seats 33 and at least two rails 34 .

[0023] Wherein, the two tracks 34 are located above the substrate 10 and can be straight or curved, and the two tracks 34 are arranged at equal intervals, such as two straight lines parallel to each other or two concentric circles.

[0024] The two sliding seats 33 are respectively straddled on the two rails 34, and the two sliding seats 33 respectively extend with supporting beams 32, and the supporting beams 32 are also connected with the flat plate 30, and the adjoining parts of the supporting beams 32, the sliding seats 33 and the flat plate 30 are all formed There are chamf...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com