Circular silicon thin-film solar cell

A technology of solar cells and silicon thin films, applied in circuits, photovoltaic power generation, electrical components, etc., can solve the problems of reducing the photoelectric conversion efficiency of solar cells, reducing the effective power generation area of the battery, and reducing the power generation power of the battery, so as to expand the effective working area, Guaranteed electrical performance and reduced ineffective area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

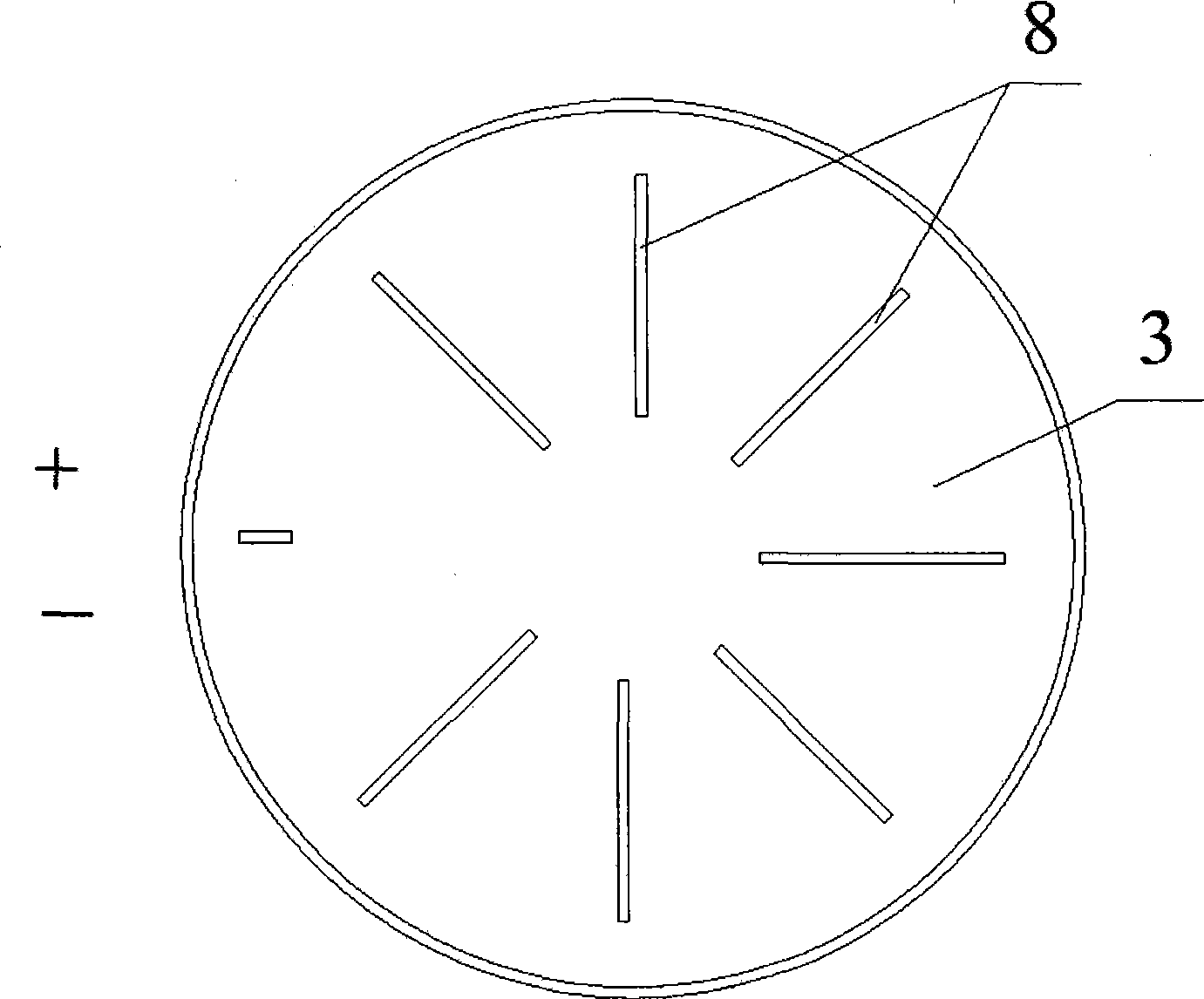

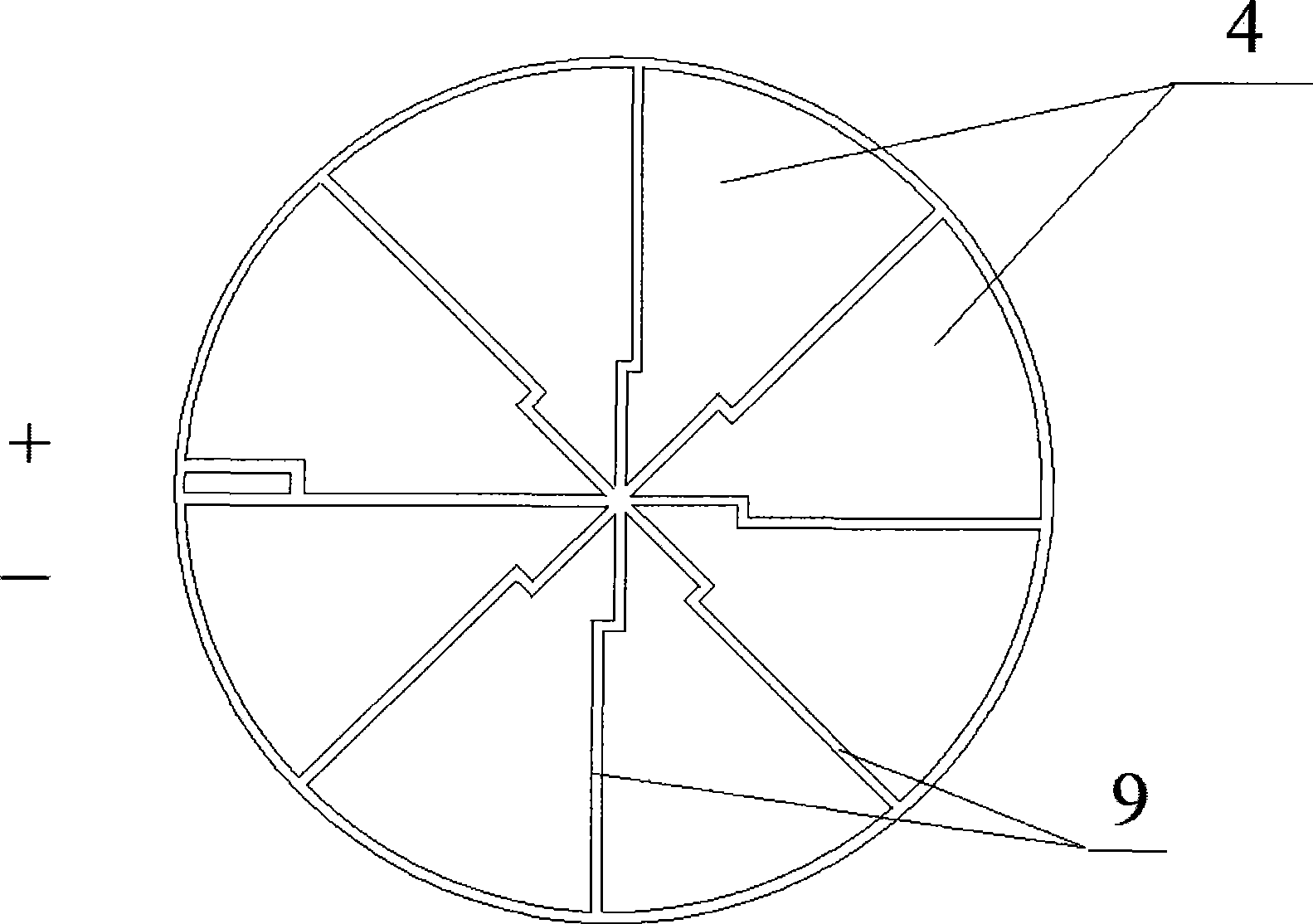

[0037] In this embodiment, the silicon thin film layer 3 is an amorphous silicon thin film, and the circular amorphous silicon thin film solar cell is composed of 8 battery cells connected in series, and the working surface of the battery cells is fan-shaped. Proceed as follows:

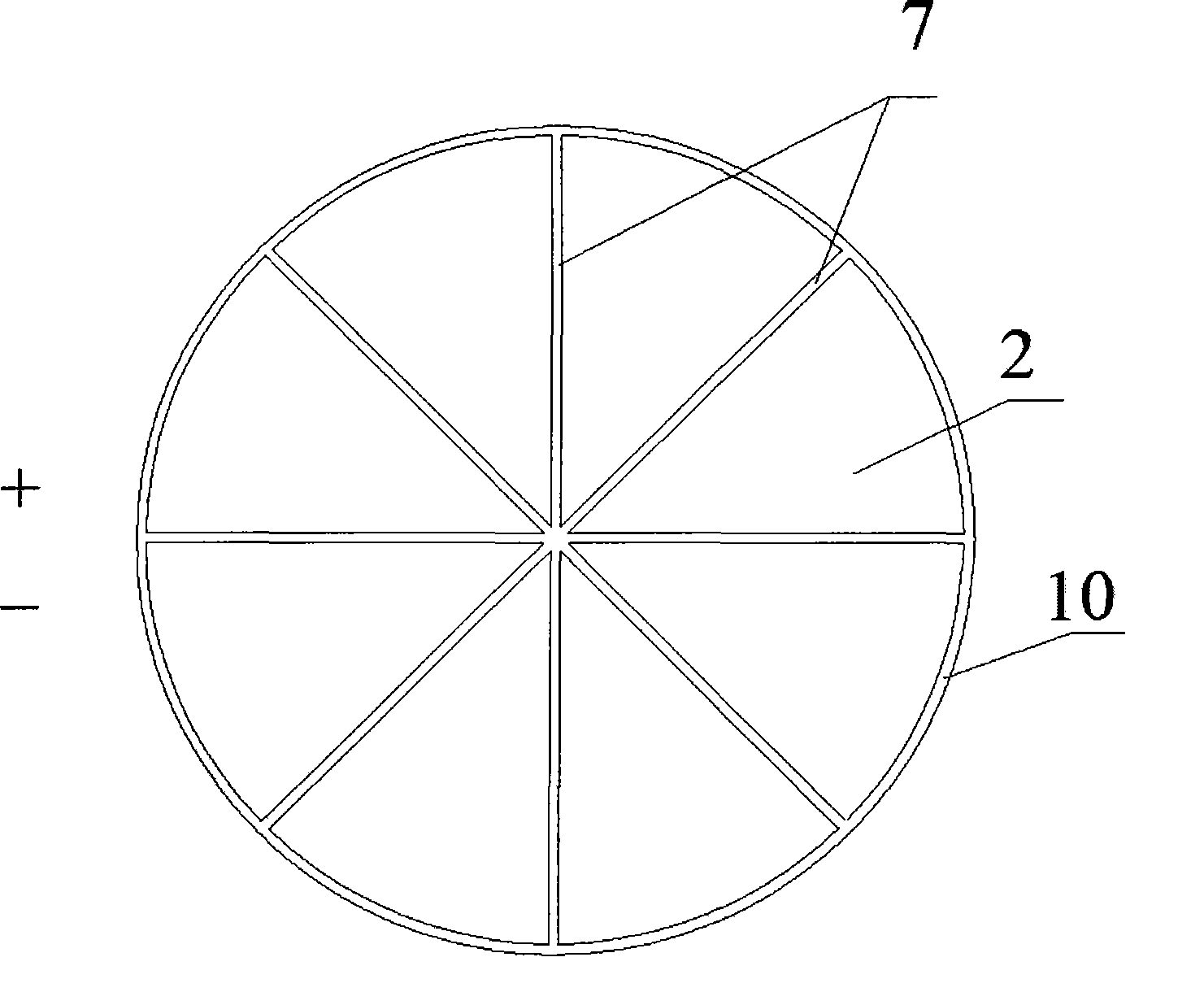

[0038] 1. Pattern making of the front electrode layer 2: deposit a layer of transparent ITO conductive film on the transparent substrate 1 to form the front electrode layer 2. Using an end-pumped vibrating mirror infrared laser marking machine, the front electrode layer 2 is etched into fan-shaped independent small blocks with equal areas and mutual insulation to form the laser isolation line 7 of the front electrode layer 2, such as figure 2 shown. The laser wavelength is 1064nm, the laser power is 10 watts, the laser acousto-optic frequency is 40KHz, the width of the laser isolation line 7 on the front electrode layer is 0.07mm, and the insulation resistance between adjacent front electrode patte...

Embodiment 2

[0047] In this embodiment, the silicon thin film layer 3 is a microcrystalline silicon thin film, and the circular microcrystalline silicon thin film solar cell is composed of 6 battery cells connected in series, and the shape of the battery cells is fan-shaped. Proceed as follows:

[0048] 1. Pattern making of the front electrode layer 2: Deposit a layer of transparent conductive film SnO on the transparent substrate 1 2 , using an end-pumped vibrating mirror infrared laser marking machine to etch the conductive film into fan-shaped independent small pieces with equal areas and mutual insulation. The laser wavelength is 1064nm, the laser power is 20 watts, the laser acousto-optic frequency is 50KHz, the width of the laser isolation line on the front electrode layer is 0.04mm, and the insulation resistance between adjacent front electrode patterns is greater than 20MΩ.

[0049] 2, deposition microcrystalline silicon layer 3: method is the same as embodiment 1, and difference ...

Embodiment 3

[0055] The silicon thin film layer 3 is an amorphous silicon thin film, and the circular amorphous silicon thin film solar cell is composed of 10 cells with irregular shapes connected in series. Proceed as follows:

[0056] 1. Patterning of the front electrode layer 2: Deposit a layer of transparent SnO on the transparent substrate 1 2 For the conductive film, an end-pumped vibrating mirror infrared laser marking machine is used to etch the conductive film of the front electrode layer into independent small pieces of irregular shape with equal areas. The laser wavelength is 1064nm, the laser power is 29 watts, the laser acousto-optic frequency is 70KHz, the laser isolation line width of the front electrode layer is 0.03mm, and the insulation resistance between adjacent front electrode patterns is greater than 30MΩ.

[0057] 2. Depositing the amorphous silicon thin film layer 3: the method is the same as that in Example 1.

[0058] 3. Laser scribing the amorphous silicon thin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com