Sealed travel switch

A travel switch and sealing structure technology, which is applied in the direction of electric switches, electrical components, circuits, etc., can solve the problems that the travel switch does not have sealing requirements, cannot meet the use requirements of ultra-long storage period and high reliability, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

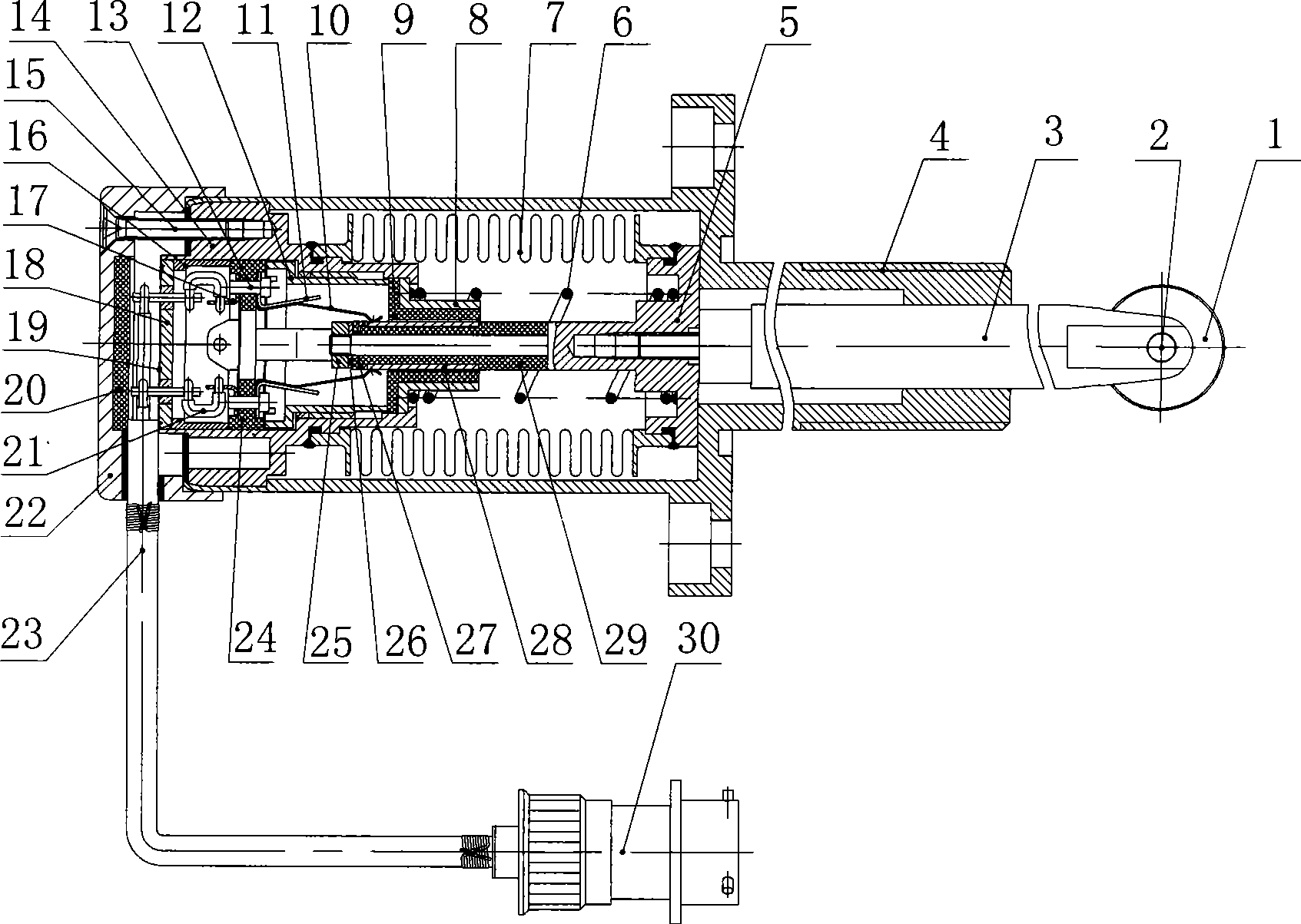

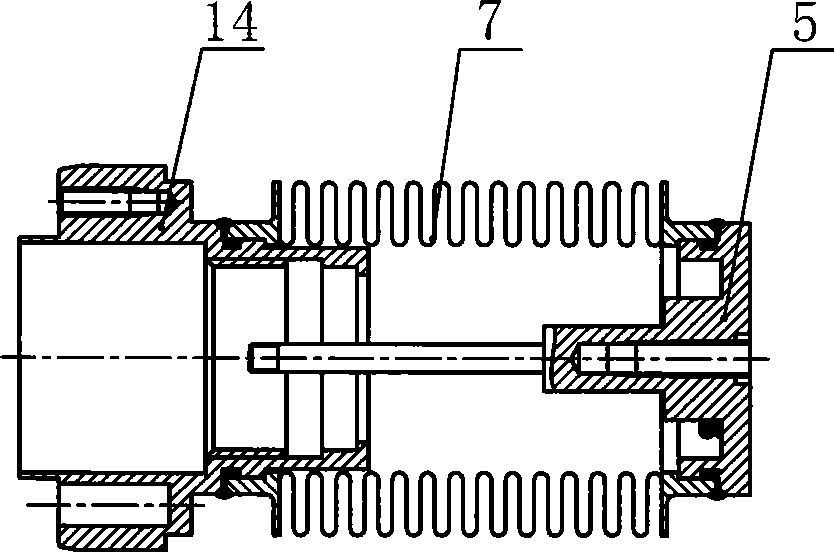

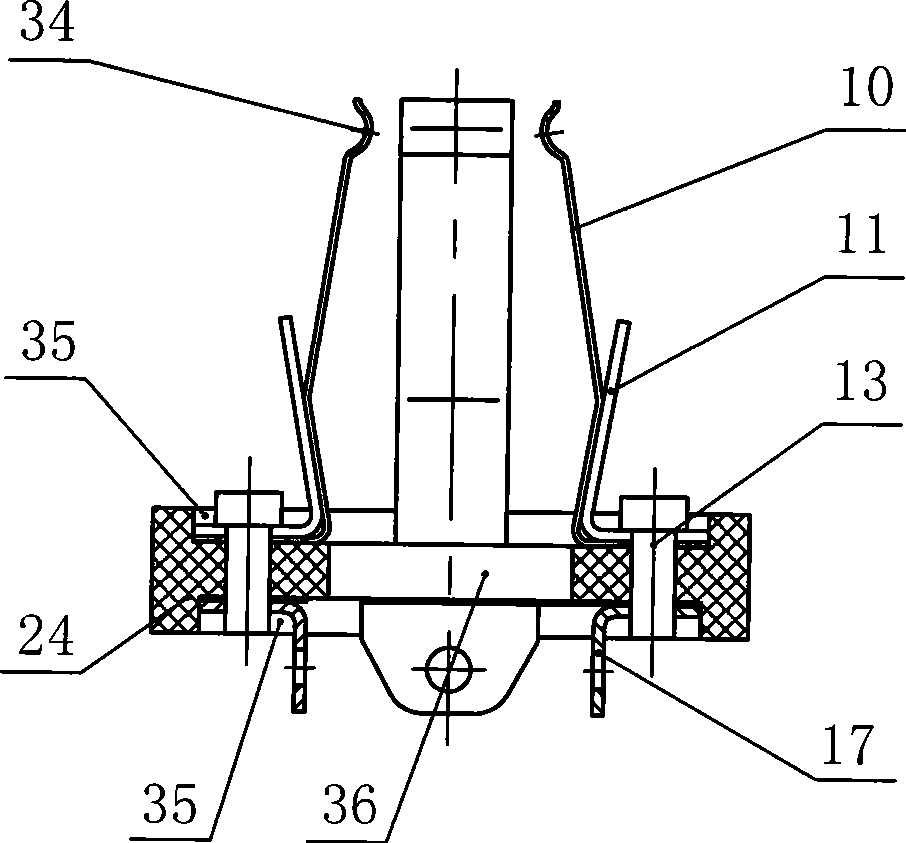

[0010] The specific embodiment of the present invention will be described in further detail below in conjunction with the accompanying drawings: a sealed travel switch includes a sealed structure, a tower contact system, a base assembly, an outer cover, a shaft, and a guide wheel. figure 1 The overall structure of the present invention is shown. Mainly composed of guide wheel 1, small shaft 2, shaft 3, outer cover 4, push column 5, spring 6, welded bellows 7, push plate 8, insulating sleeve 9, contact piece 10, supporting piece 11, fixed sleeve 12, rivet 13 , Base 14, Screw 15, Straight sleeve 16, Terminal 17, Base combination 18, Insulation gasket 19, Insulation baffle 20, Back cover 21, Transition lead 22, Cable 23, Base 24, Nut 25, Flat washer 26. The outer insulating sleeve 27, the movable contact 28, the inner insulating sleeve 29 and the connector 30 etc. are composed. The guide wheel 1 is riveted on the shaft 3 through the small shaft 2, and the guide wheel 1 can rotat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com