Method for producing movable contact body with protrusion

A manufacturing method and a technology for a contact body, applied in chemical instruments and methods, electronic equipment, lamination, etc., can solve the problems of shredding, difficulty in ensuring the installation stability of protruding parts, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0058] Below, refer to Figure 1 to Figure 18 , to describe the embodiment of the present invention. Components that are the same as those described in the prior art are denoted by the same symbols, and detailed description thereof will be omitted.

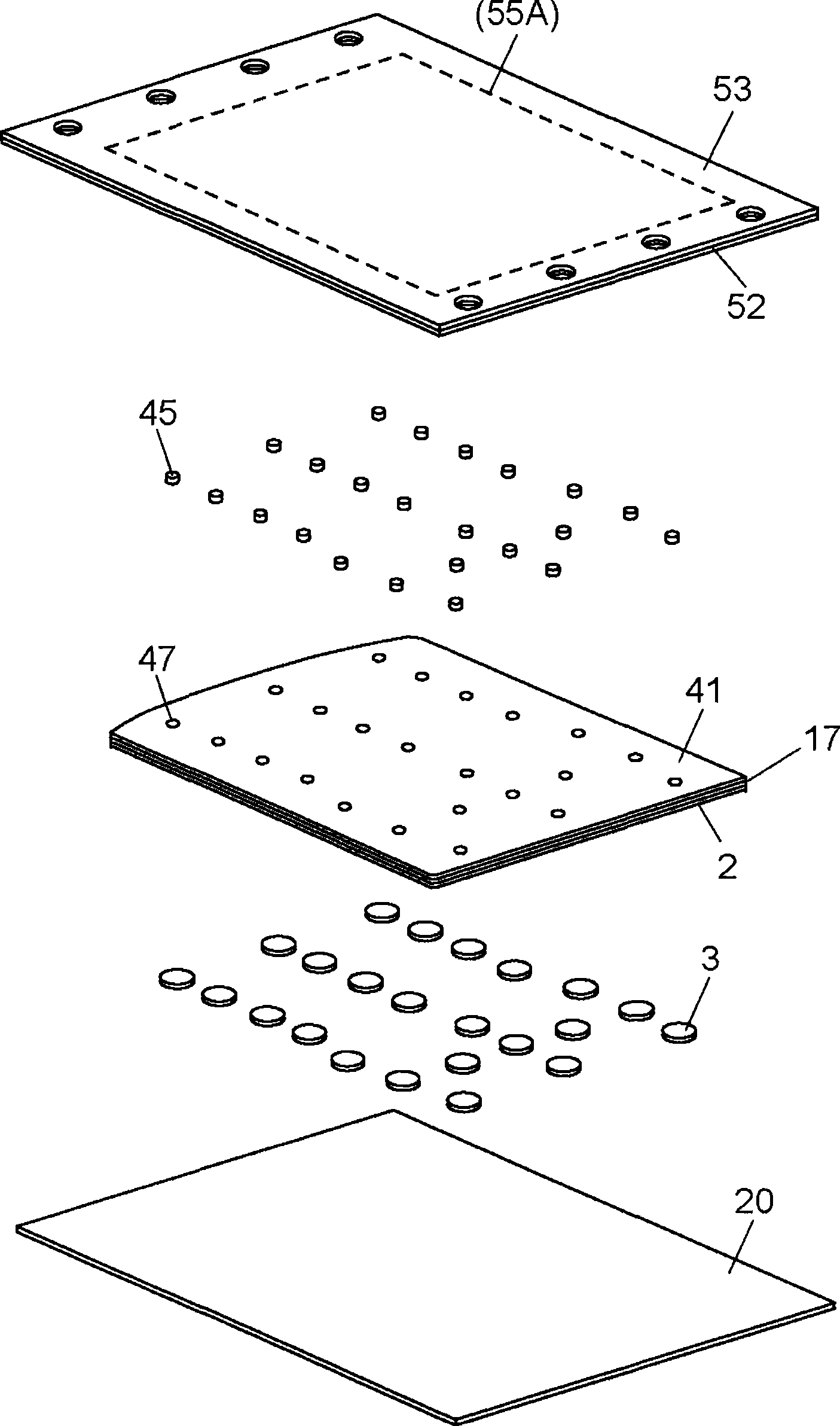

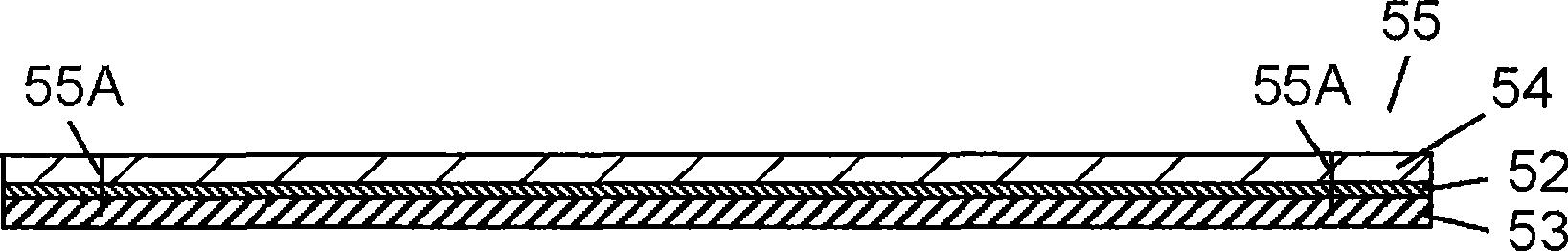

[0059] figure 1 It is a cross-sectional view of a movable contact body with a protrusion manufactured by a method of manufacturing a movable contact body with a protrusion according to an embodiment of the present invention. figure 2 yes figure 1 An exploded perspective view of the movable contact body with protrusions shown.

[0060] In the figure, a functional layer 17 constituting an EL element is stacked on the lower surface of a translucent base film 41 made of a TPU film cut into a predetermined shape. Further, on the lower surface of the functional layer 17, the movable contacts 3 are bonded and held at predetermined positions through the adhesive layer 2, respectively. At a position on the base film 41 correspondin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com