Mirror-vibrating laser three-dimensional scanning system

A laser three-dimensional scanning system technology, applied in laser welding equipment, optics, optical components, etc., can solve the problems of increased laser power loss, poor stability, and complex optical path, and achieve the effects of reduced cost, improved stability, and simple optical path

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] Hereinafter, the method of the present invention will be further described in detail through the accompanying drawings and examples.

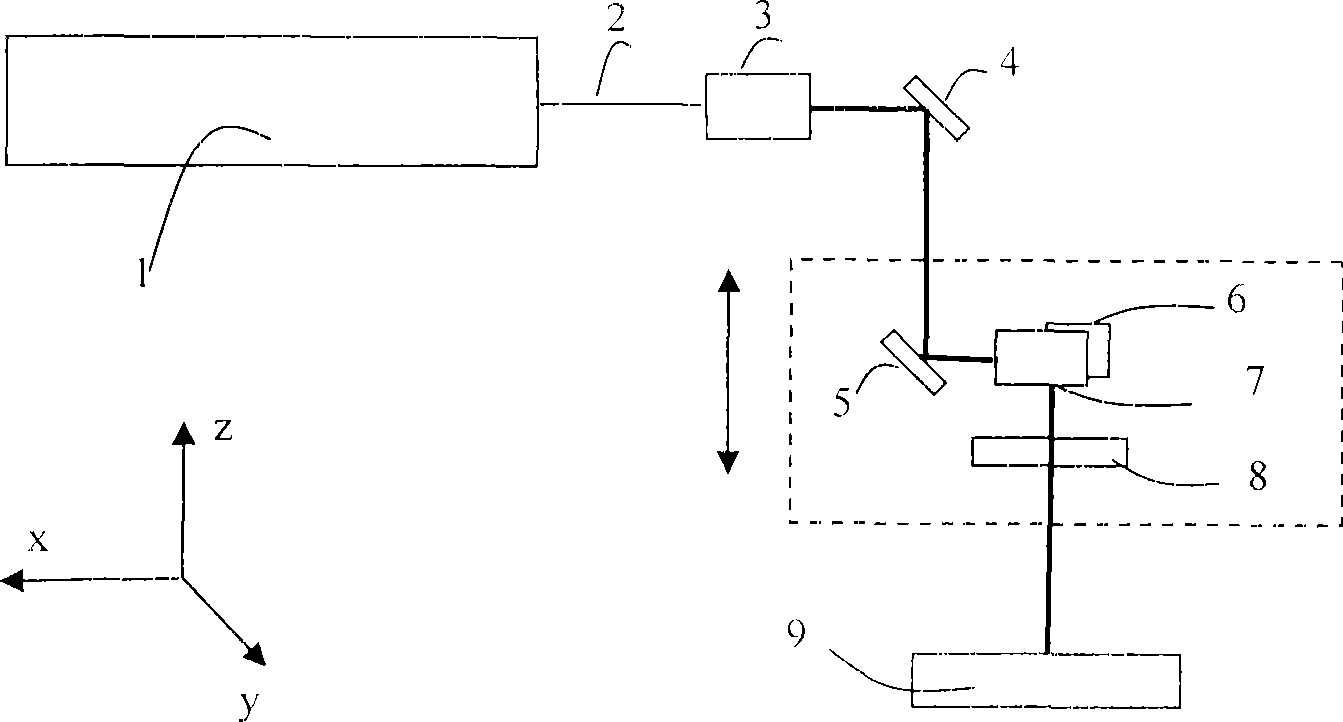

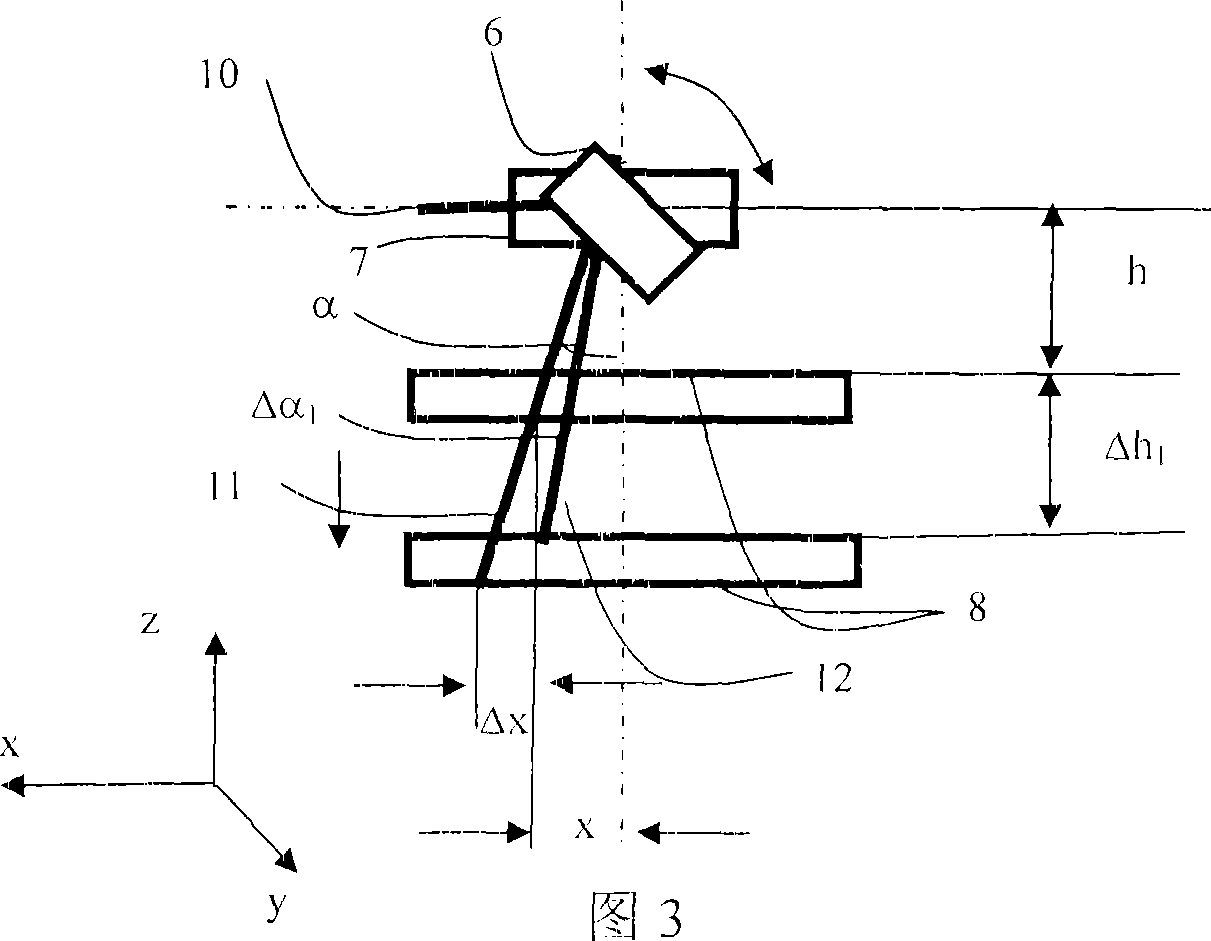

[0015] The galvanometer laser scanning system is divided into two parts; one part is the xy two-axis scanning galvanometer, and the other part is the scanning focusing lens. The xy two-axis scanning galvanometer is fixed and does not move in the z-axis direction, while the scanning focus lens can move up and down relative to the xy two-axis scanning galvanometer in the z-axis direction, and automatically adjust the focus position in the z-axis direction to achieve three-dimensional processing purpose.

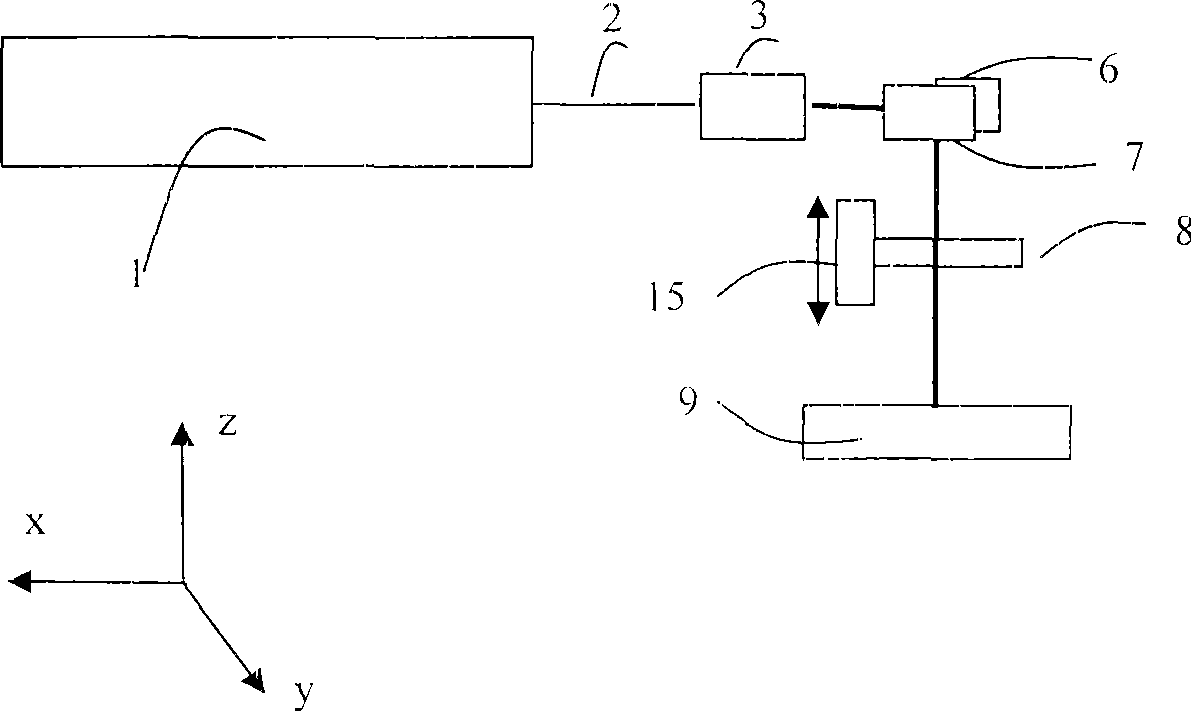

[0016] A system that implements the above method, such as figure 2 As shown, the system of the present invention consists of a laser 1, a beam expander 3, an x-axis scanning galvanometer 6, a y-axis scanning galvanometer 7, a scanning focusing lens 8, a z-axis moving mechanism 15 and a control system.

[0017] The mirror centers of the x-axis...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com