Method for demarcating multi line scan video cameras

A line-scanning camera and calibration method technology, which is applied in the field of multiple line-scanning camera calibration, can solve the problems of affecting the synchronization of cameras, merging of images, and the difficulty of accurate size calculation, so as to achieve the effect of improving calibration efficiency and increasing calibration accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

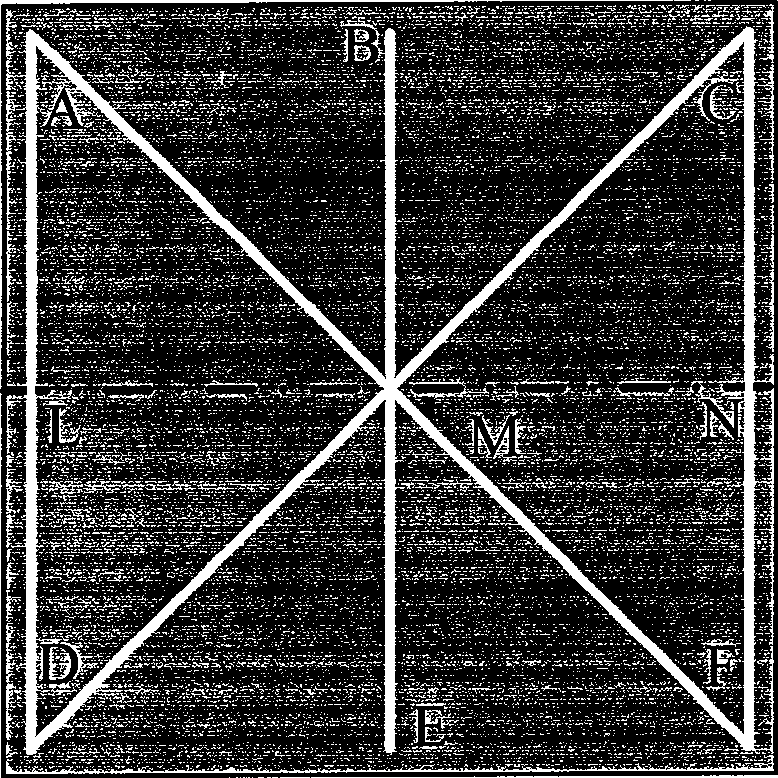

[0039] see figure 2 , the method for the calibration of multiple line scan cameras of the present invention is designed with a calibration plate 1, which is a rectangular plate, on which 8 narrow slit light sources are arranged around and diagonally, and the four corner endpoints are respectively defined as A and C , F, D, the intersection point of the diagonals is M, and the midpoints between the endpoints A, C, F, and D are B, N, E, and L respectively; so far AD, CF, AM, BM, CM, DM, and EM are formed , 8 narrow slit light sources of the FM line, LN is the horizontal reference line; the 8 light sources are controlled by independent power switches;

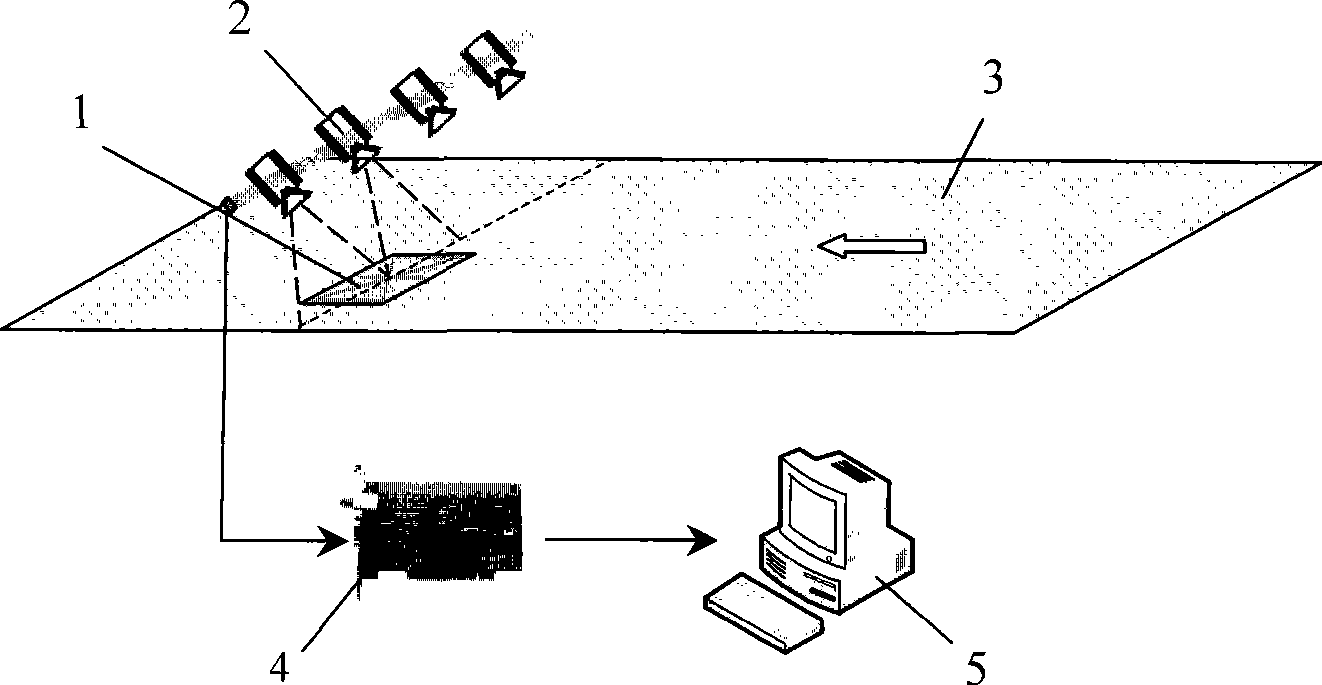

[0040] see figure 1 , the camera 2 is installed on a multi-degree-of-freedom adjustment mechanism, the installation position of the camera is basically determined, and precise positioning is required. The output of the camera 2 is stored in the computer 5 via the image acquisition card 4 .

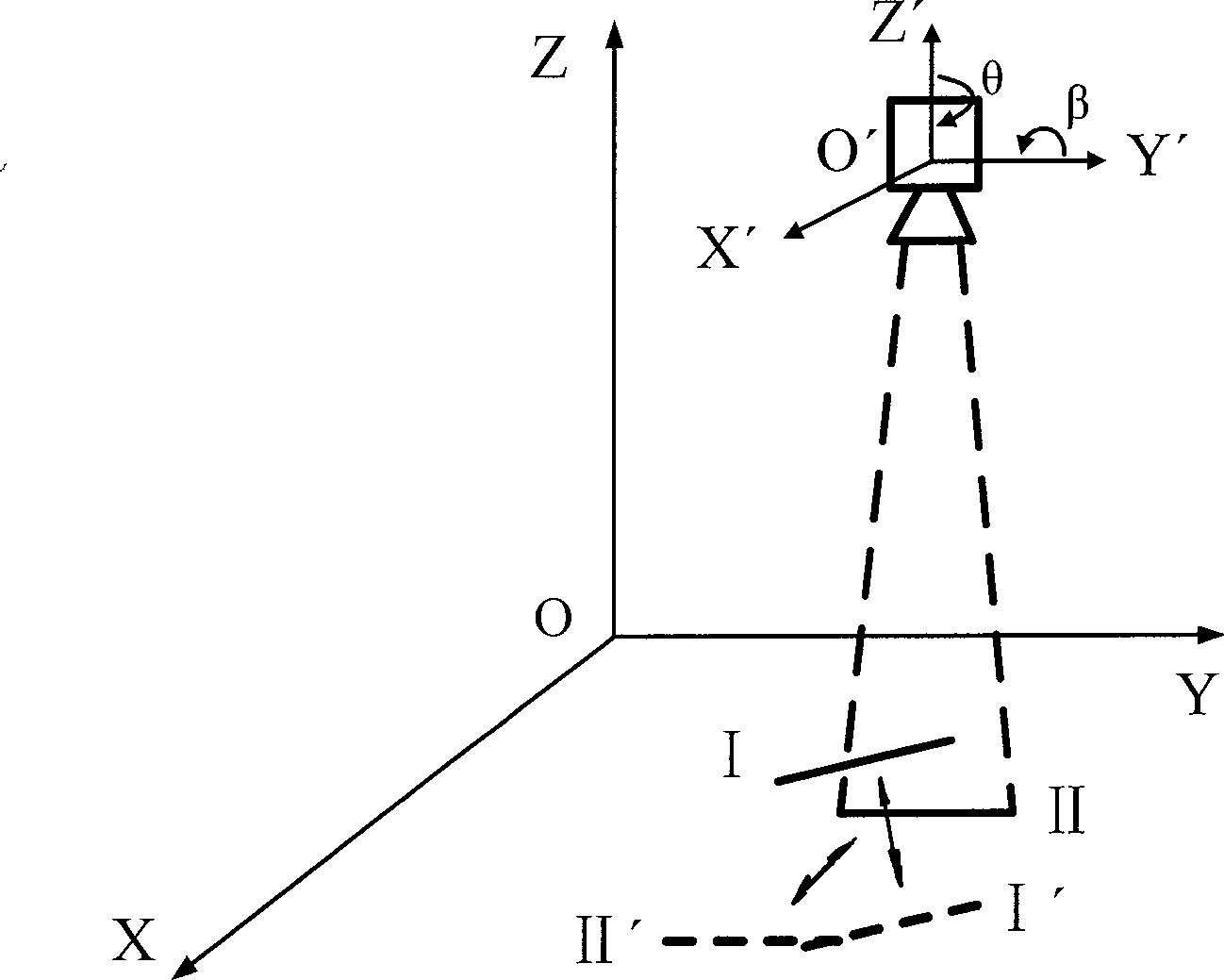

[0041]Two reference coordinate syst...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com