Solar groove type and flat-plate type combine heat-collecting solution regeneration method, device thereof and applications

A solution regeneration, flat-plate technology, applied in the direction of solar thermal devices, solar collectors, solar collectors using working fluid, etc., can solve the problem of complex regeneration process and regeneration equipment, low solution concentration and regeneration efficiency, and unfavorable Solution regeneration and other problems, to achieve the effect of increasing regeneration concentration, improving solar energy utilization efficiency, and high solar energy utilization efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

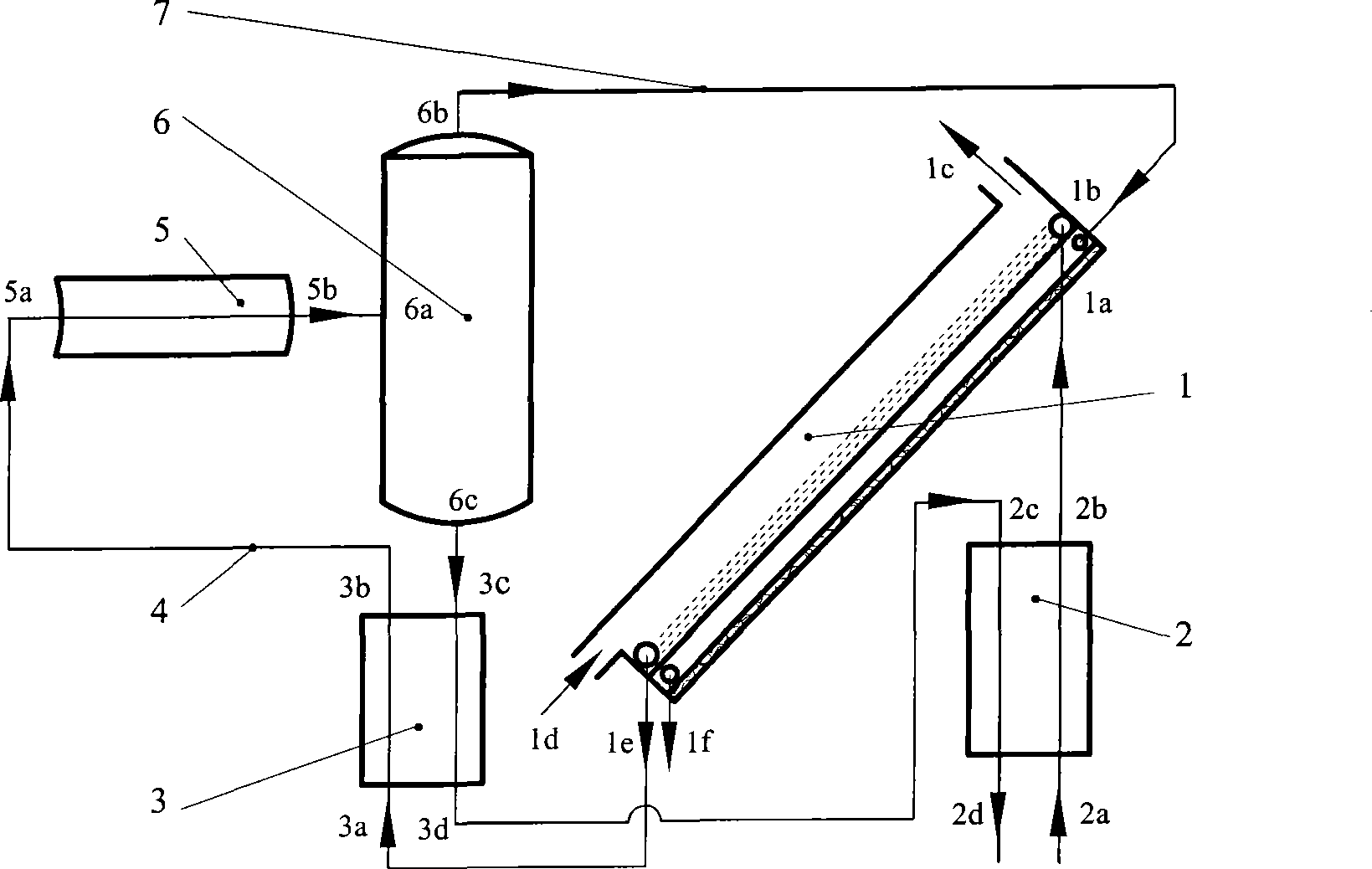

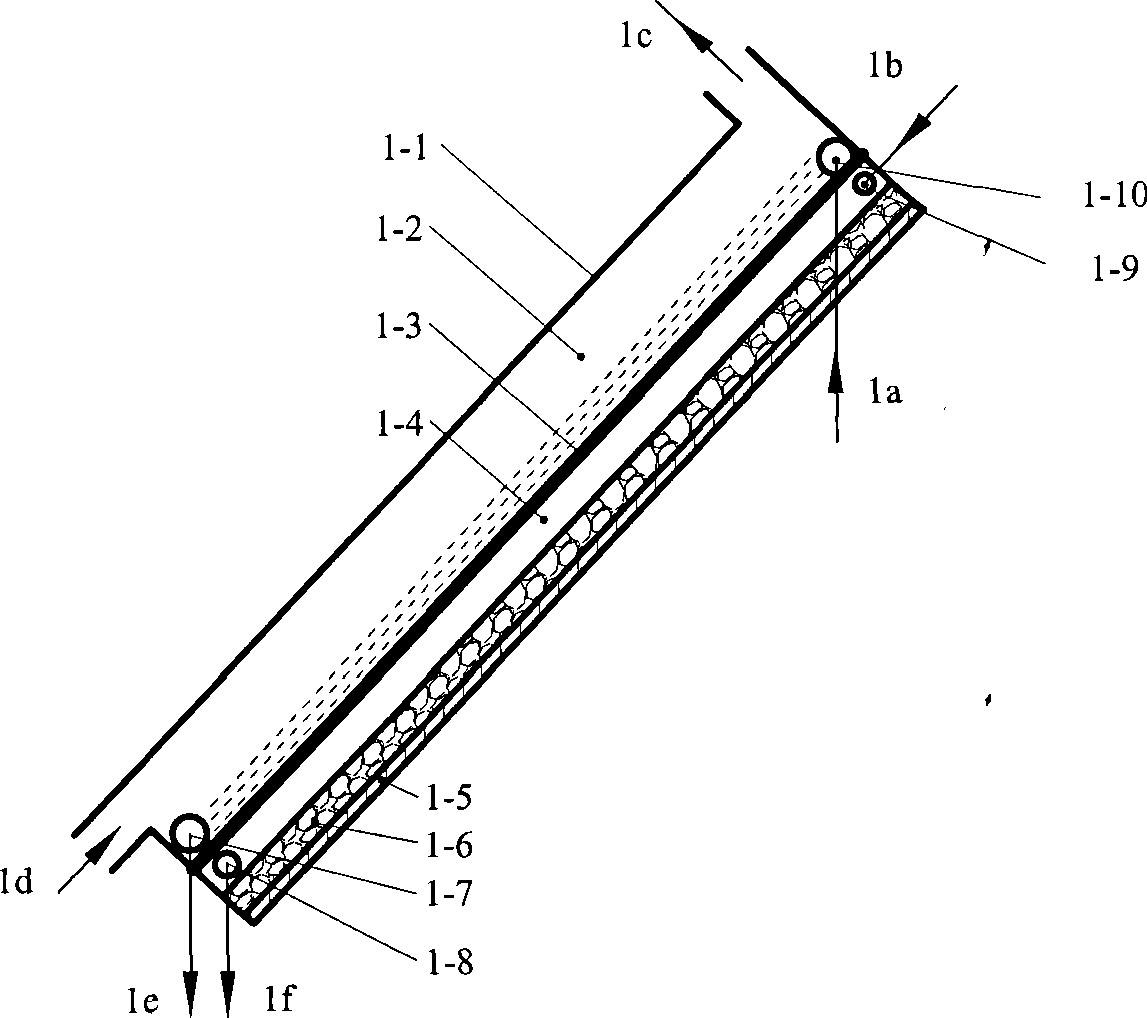

[0037] Such as figure 1As shown, a solar trough type and flat plate type combined heat collecting solution regeneration device of the present invention is externally connected to a dehumidifier, and the device includes a low temperature casing heat exchanger 2, a flat plate type heat collecting regenerator 1, and a high temperature casing heat exchanger 3 , trough heat collector 5 and vapor-liquid separator 6; according to the delivery direction of the solution in the solution loop of the device, the dilute solution inlet port I 2a of the low-temperature casing heat exchanger 2 is connected with the dehumidifier by a pump, and the dilute solution outlet End I 2b is connected to the dilute solution inlet port II 1a of the flat-plate heat collector regenerator 1, and the relatively concentrated solution outlet I le of the flat-plate heat collector regenerator 1 is connected to the relatively concentrated solution inlet port I of the high-temperature casing heat exchanger 3 3a co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com