Air entraining system for high-pressure hydrogenation stations

A technology of high-pressure hydrogen and hydrogen refueling stations, applied in the field of refueling systems, to achieve the effects of increasing gas extraction rate, reducing sampling costs, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

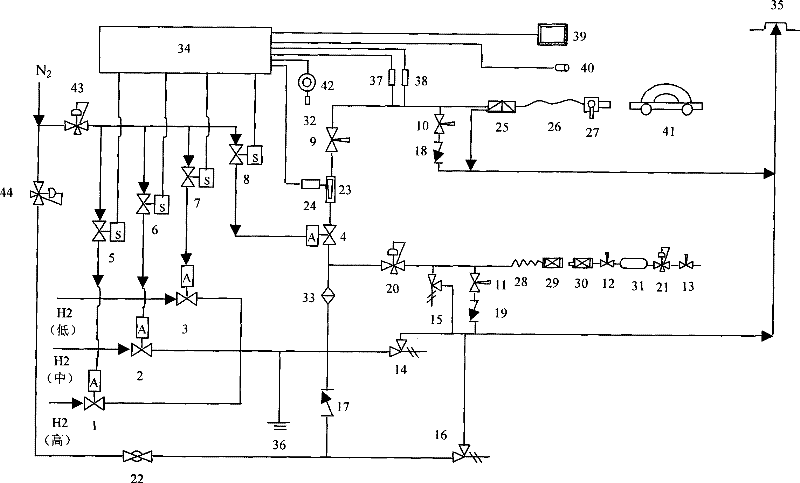

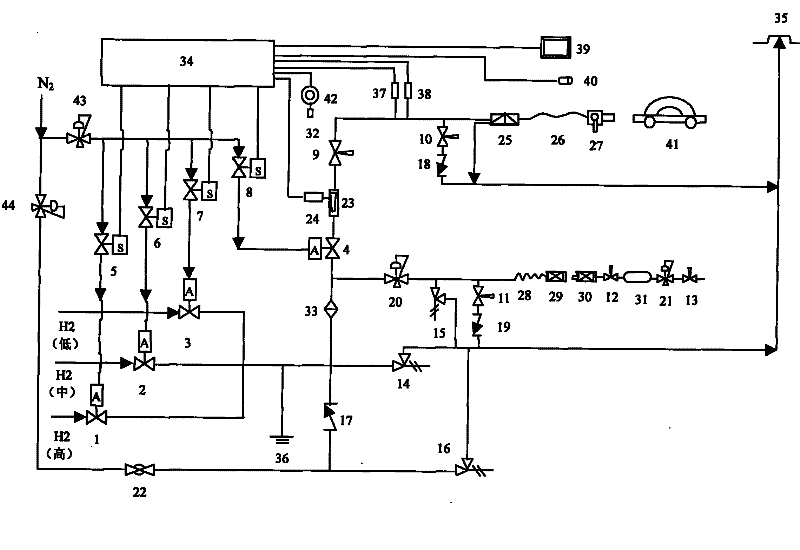

[0030] Embodiment 1 Sampling operation: turn on the power of the controller 34 and select the sampling mode. If it is necessary to take a sample of the hydrogen in the high-pressure hydrogen storage bottle, connect the solenoid valve 5, driven by the low-pressure nitrogen, the pneumatic valve 1 is opened, the high-pressure hydrogen passes through the pneumatic valve 1, flows through the filter 33, reaches the pressure regulating valve 20, and quickly Connect the joint 29 to 30, open the needle valves 12 and 13, close the pressure regulating valve 21, slowly open the pressure regulating valve 20 until the sampling bottle has positive pressure, slowly open the pressure regulating valve 21, purge the sampling bottle with sample hydrogen, and then close the needle Valve 13, pressure regulating valve 21, adjust the outlet pressure of pressure regulating valve 20 until the inlet pressure of pressure regulating valve 21 reaches the pressure required for sampling, then close pressure r...

Embodiment 2

[0031] Embodiment 2 Filling operation: switch on the power supply of the controller 34, select the filling mode, and determine the relevant parameters, such as whether the filling quality or the pressure of the on-board hydrogen bottle is used as the filling end point, the rate point at which the three-stage hydrogen storage bottles switch between each other, Whether there is communication with the vehicle being filled when filling. After the parameters are set, the solenoid valve 8 is opened, driven by the low-pressure nitrogen, the pneumatic valve 4 is opened, and the filling preparation state is entered. Insert the hydrogenation gun 27 into the gas receiving head of the vehicle 41 to be filled, turn on the switch of the hydrogenation gun, and give a hydrogenation instruction. The controller 34 will open the electromagnetic valve 7 according to the preset program, open the pneumatic valve 3 for a few seconds, and then close the electromagnetic valve 7 and the pneumatic valve...

Embodiment 3

[0032] Embodiment 3 Filling rate control: When filling, when the hydrogenation system is not connected to the vehicle-mounted hydrogen bottle to be filled with a communication interface, during the filling process, the controller 34 will intermittently turn off or off according to the preset program. Instructions for opening the solenoid valve 8 and the pneumatic valve 4, that is, when the solenoid valve 8 and the pneumatic valve 4 are closed, the controller 34 calculates according to the quality of the filled hydrogen gas measured by the mass flow meter 23 and the actual pressure of the filled hydrogen bottle. The actual temperature in the hydrogen outlet bottle is then compared with the allowable temperature curve set by the program. If the actual temperature is close to the allowable temperature, the solenoid valve 8 and pneumatic valve 4 are closed; if the actual temperature is lower than the allowable temperature, the solenoid valve 8 and pneumatic valve are closed. Valve ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com