High mining height workface stepped coal cutting process

A step-type, large mining height technology, applied in cutting machinery, ground mining, earth-moving drilling, etc., can solve the problem of safe and efficient mining, but no breakthrough has been made, the problem of surrounding rock control is difficult to effectively solve, and the mining technology cannot Problems such as normal implementation, to achieve the effect of wide practicability, easy operation, and prevention of end face caving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] Embodiments of the present invention will be further described below in conjunction with accompanying drawings:

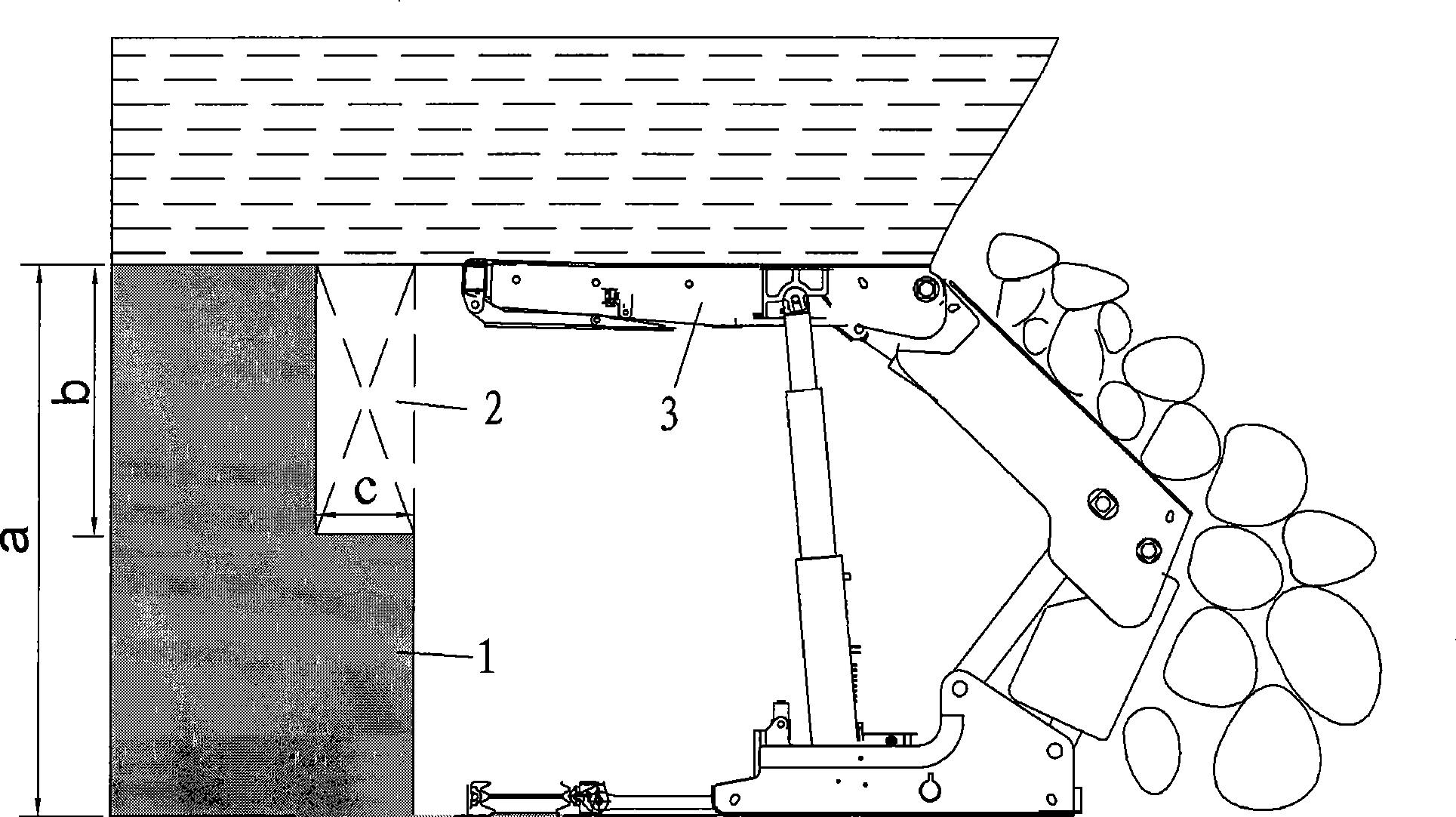

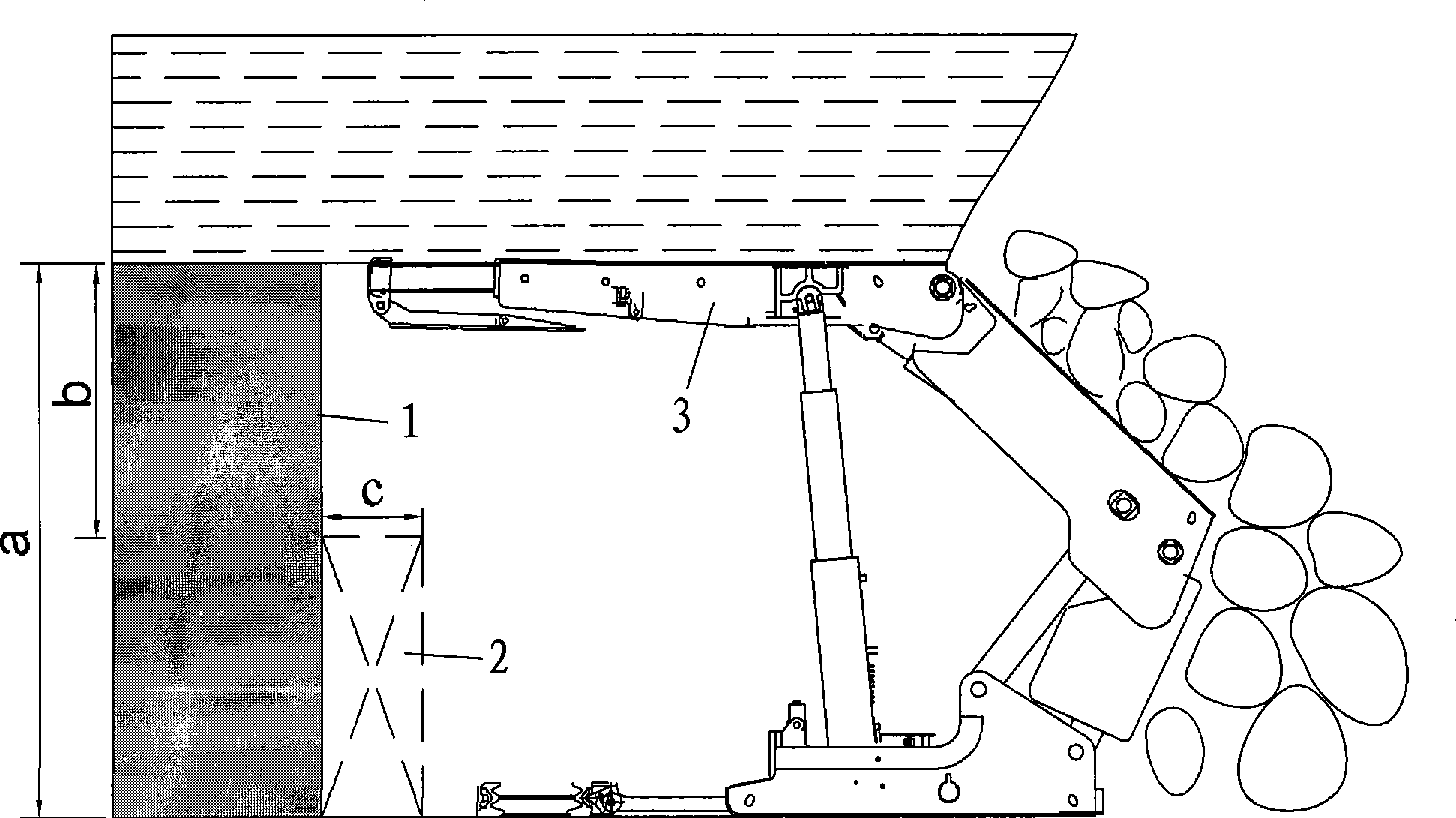

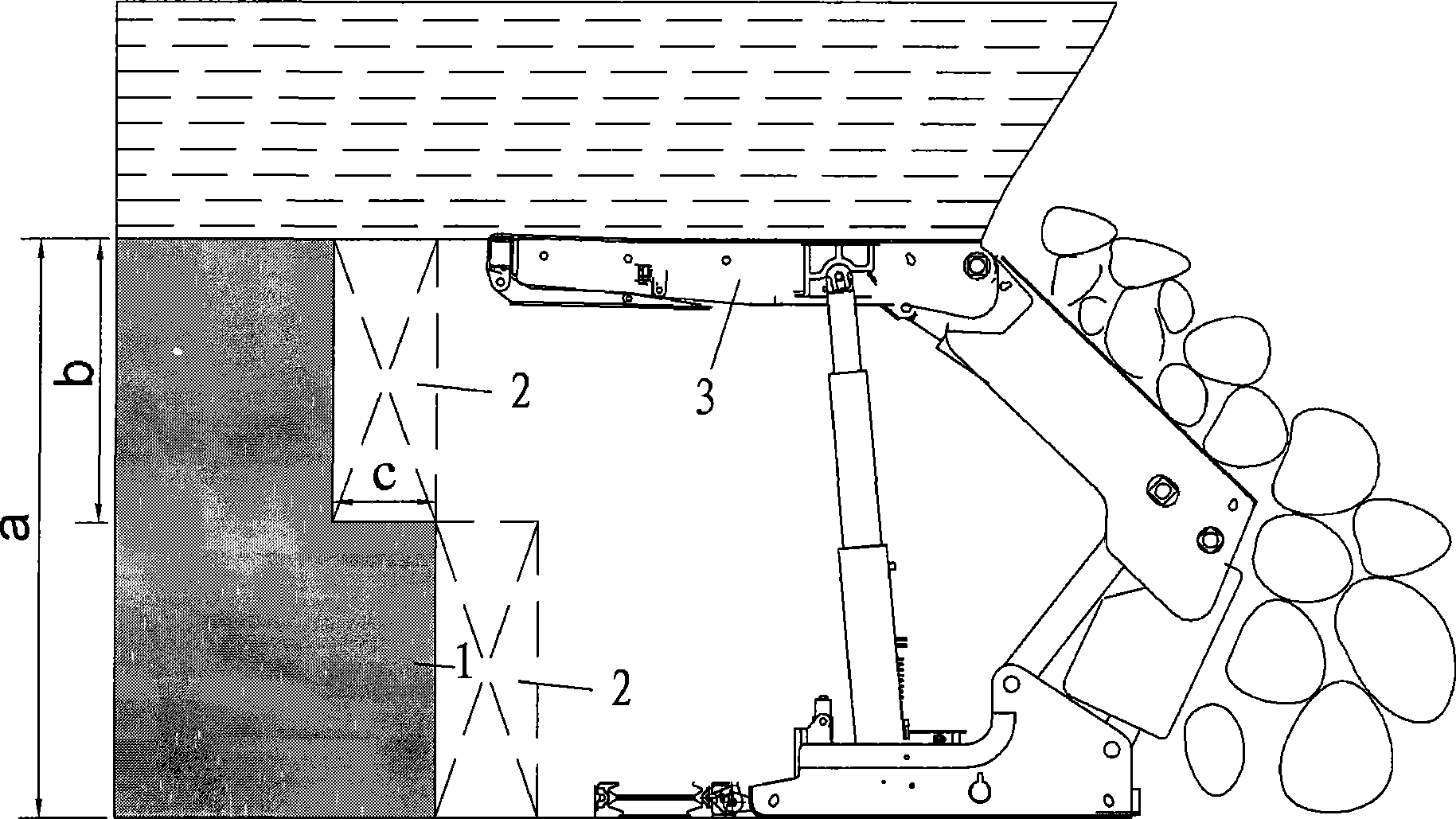

[0012] The step-type coal cutting process of large mining height fully mechanized mining of the present invention: in the fully mechanized mining working face, adopt the method of two-way step-type coal cutting of the shearer, and use the shearer drum 2 along the direction of the thickness of the coal seam, first to the coal wall 1 Partially cut the coal so that the coal wall 1 forms a step, figure 1 shown. Carry out coal cutting to the step of coal wall 1 lower part then, figure 2 shown. Then the support 3 is moved, and each operation cycle adopts step-type coal cutting along the thickness direction of the coal seam. The upper step is mined first, the lower step is left, and then the lower step is mined, and the cycle is carried out in order to avoid a coal wall. Help and end capping. Or directly set the drum of the shearer as two front and rear, and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com