Shape preserving high-altitude balloon

A technology of high-altitude balloons and spheres, applied in the direction of balloon aircraft, etc., can solve the problems of high-altitude balloons that cannot achieve fixed-point suspension, poor shape-retaining ability, and shape change, and achieve good stiffness, good shape-retaining ability, and reduce weight.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

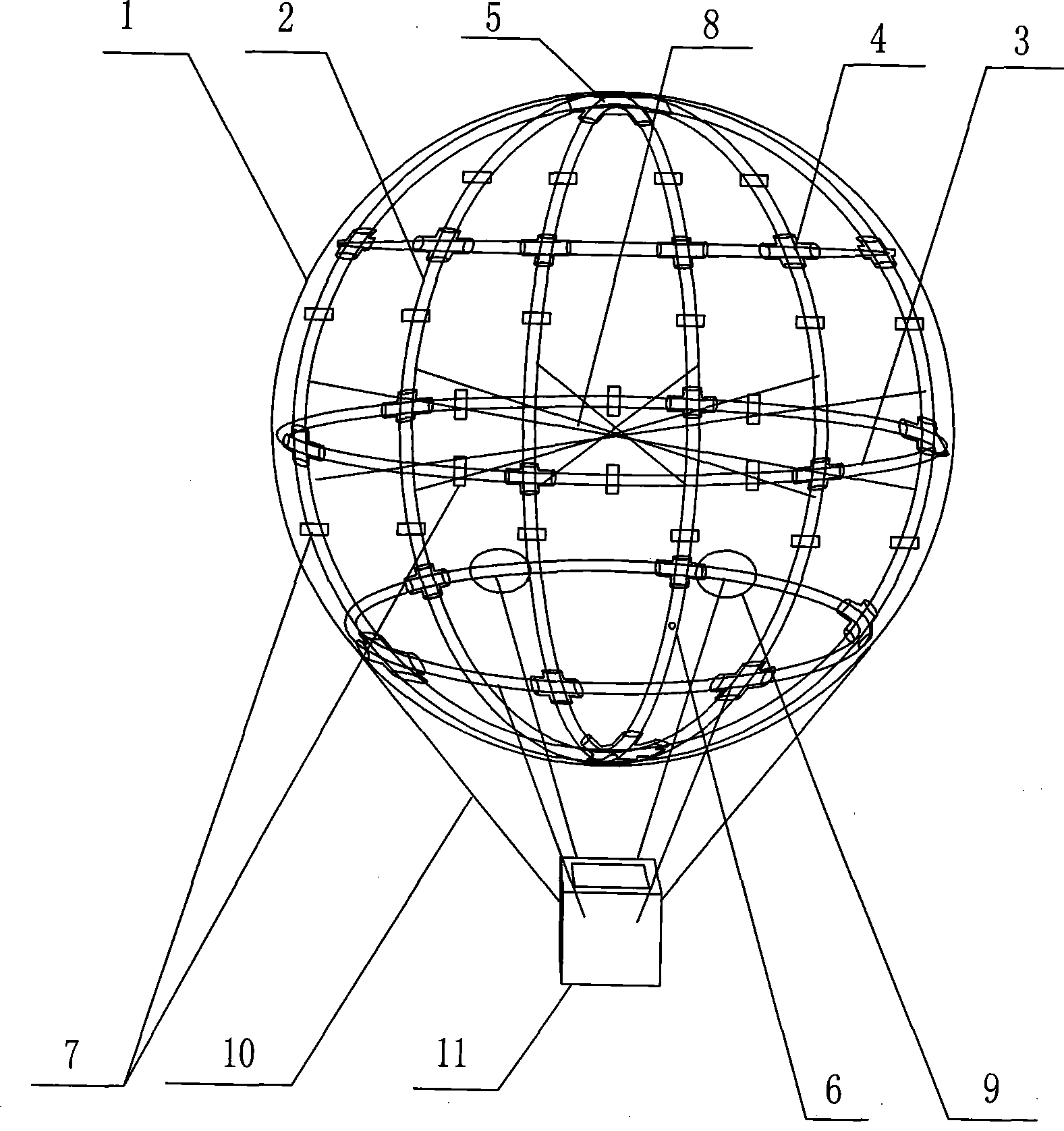

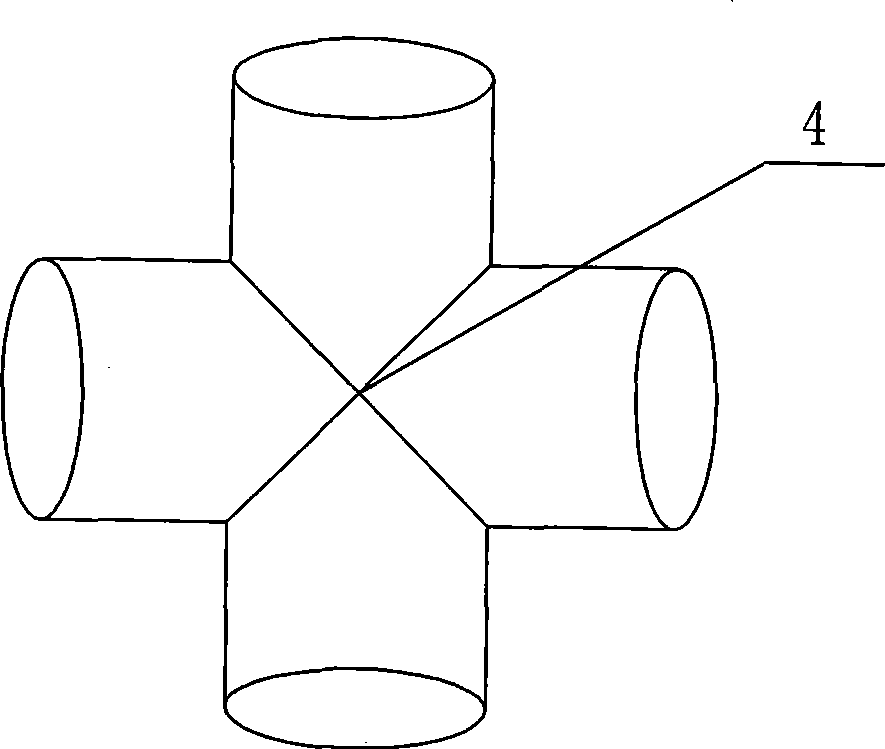

[0007] Specific implementation mode one: combine Figure 1 ~ Figure 4 Describe this embodiment, this embodiment comprises sphere, suspension cable 10 and payload 11, and described sphere comprises skin 1, a plurality of first inflatable skeletons 2, a plurality of second inflatable skeletons 3, a plurality of four-way 4, two A connecting piece 5 and a plurality of connecting pieces 7, a plurality of second inflatable skeletons 3 are arranged on each warp of the sphere, and a plurality of first inflatable skeletons 2 are arranged on each latitude of the sphere, and the first inflatable skeleton 2 is arranged on each latitude of the sphere. Air intake holes 6 are opened on the skeleton 2, and the upper junctions and lower junctions of a plurality of first inflatable skeletons 2 are respectively communicated through connecting pieces 5, and the junctions between the first inflatable skeleton 2 and the second inflatable skeleton 3 pass through four 4 communicates, the skin 1 is fi...

specific Embodiment approach 2

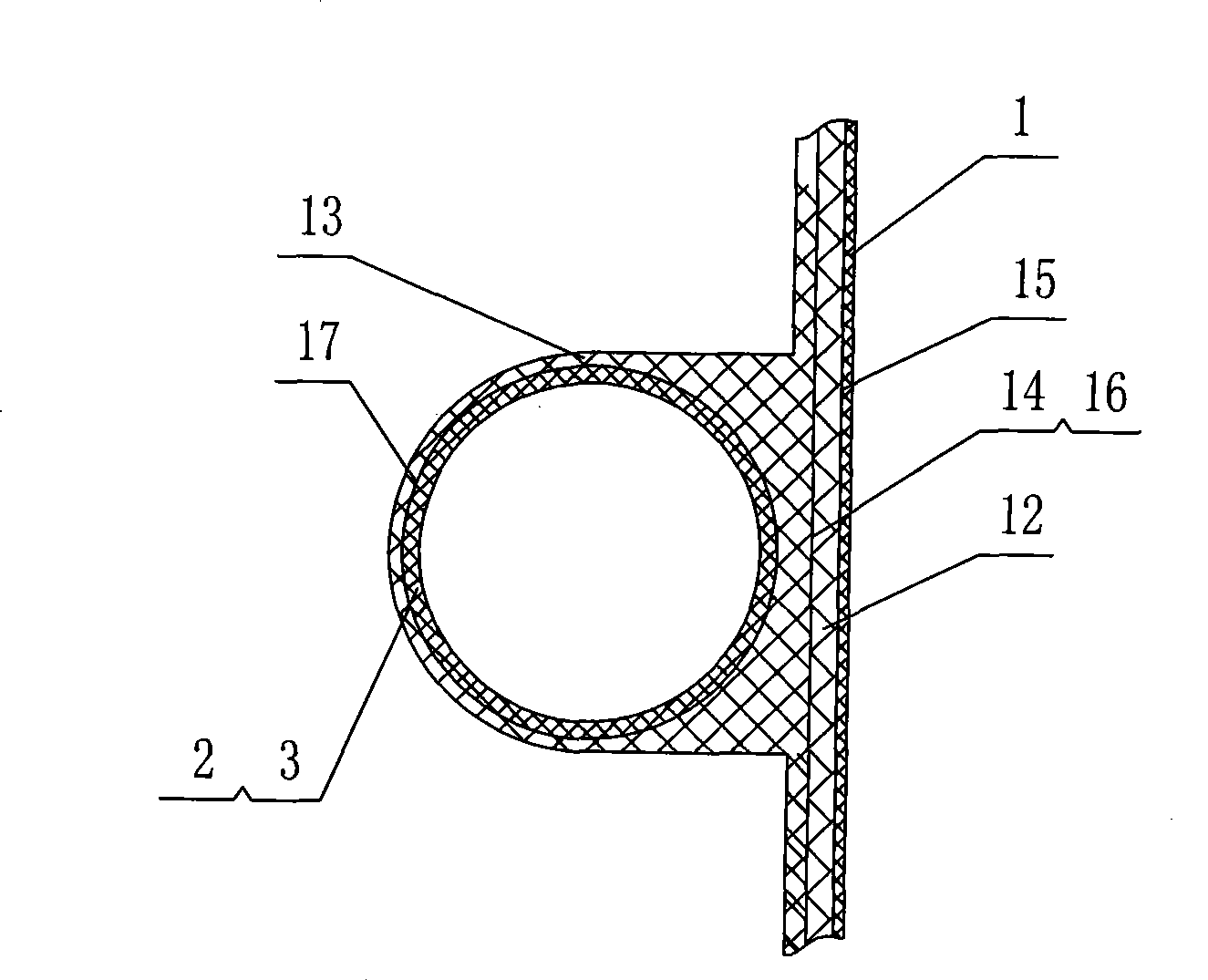

[0008] Specific implementation mode two: combination image 3 and Figure 4 To illustrate this embodiment, the connector 7 of this embodiment is composed of a first adhesive layer 12 and a second adhesive layer 13, the inner side 14 of the first adhesive layer 12 is connected to the outer side 16 of the second adhesive layer 13 The outer surface 15 of the first adhesive layer 12 is bonded to the skin 1, and the inner surface 17 of the second adhesive layer 13 is bonded to a plurality of first inflatable skeletons 2 and a plurality of second inflatable skeletons. The outer surfaces of the skeleton 3 are bonded together. With such a setting, the shape retention ability is better. Other compositions and connections are the same as in the first embodiment.

specific Embodiment approach 3

[0009] Specific implementation mode three: combination figure 1 This embodiment is described. The difference between this embodiment and the first embodiment is that the sphere is further provided with a reinforcement patch 9 , and the reinforcement patch 9 is pasted at the joint between the suspension cable 10 and the skin 1 . Such setting avoids damage to the skin and increases the payload. Other compositions and connections are the same as in the first embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com