A magnetic core holder

A technology of magnetic core base and round base, applied in printing, typewriter and other directions, can solve the problems of unreasonable design, dislocation of structure, inaccurate size, etc., and achieve the effect of overcoming unreasonable design, reasonable design and precise structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

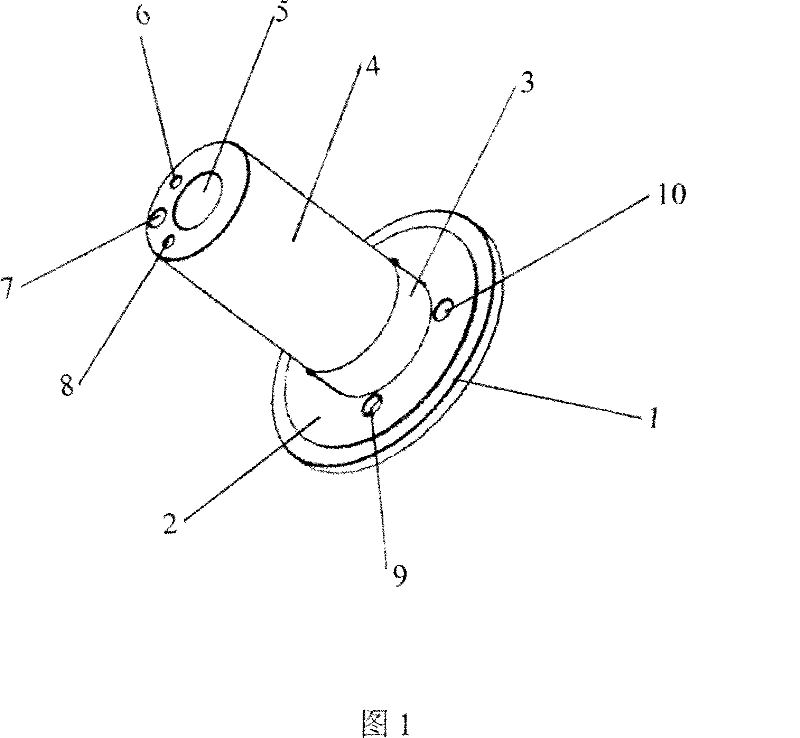

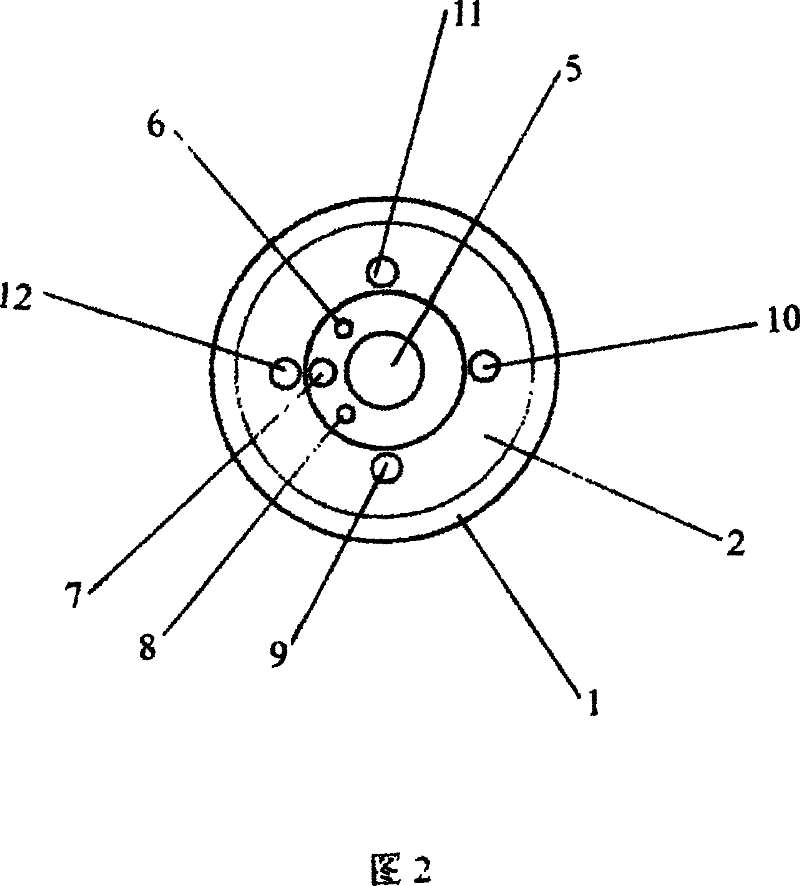

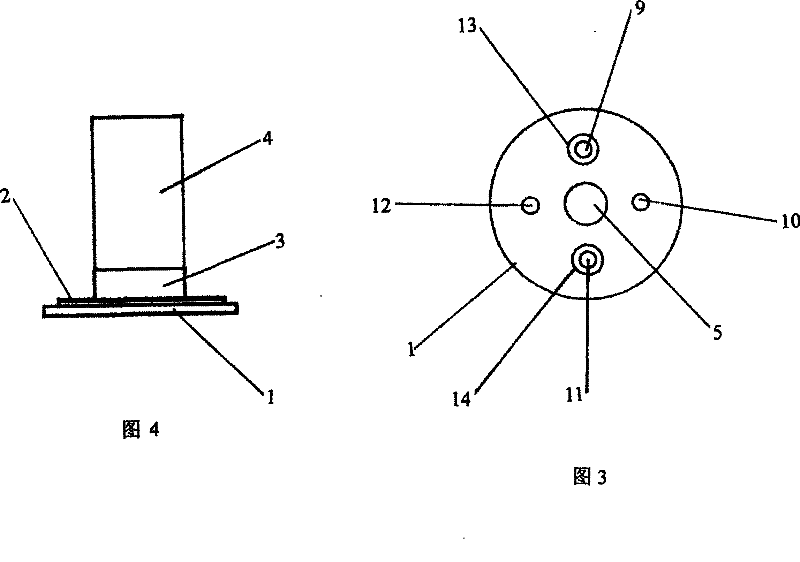

[0010] The present invention will be further described below in conjunction with accompanying drawing:

[0011] A magnetic core seat, including a base and a hole, is characterized in that the magnetic core seat is composed of a circular base 1, a circular step 2, a first circular body 3, and a second circular body 4; the circular base 1 is a hollow disc , there is a central hole in the center, the diameter of the outer circle of the circular base 1 is 44.45mm, the height of the circular base 1 is 2.344mm, the upper round edge and the lower round edge of the circular base 1 are each chamfered at 45 degrees, and the chamfering distance is 0.25- 0.5mm; a layer of circular steps 2 is also connected on the top of the circular base 1. The circular steps 2 are also a hollow disc with a central hole in the center. The diameter of the outer circle of the circular steps 2 is 38.1mm, and the height of the circular steps 2 is 0.5mm; the first torus 3 is connected above the circular step 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com