Method for suppressing vibration and device therefor

A vibration suppression and flutter technology, which is applied in the direction of manufacturing tools, metal processing machinery parts, maintenance and safety accessories, etc., can solve the problems of rotation speed reduction, effort, increase, etc., to prevent the rotation speed from decreasing or Increased effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] Hereinafter, examples of embodiments according to the present invention will be described with reference to the drawings as appropriate. In addition, the form of this invention is not limited to this example.

[0032] [the first mode]

[0033] Hereinafter, a vibration suppressing device according to one embodiment of the present invention will be described with reference to the drawings.

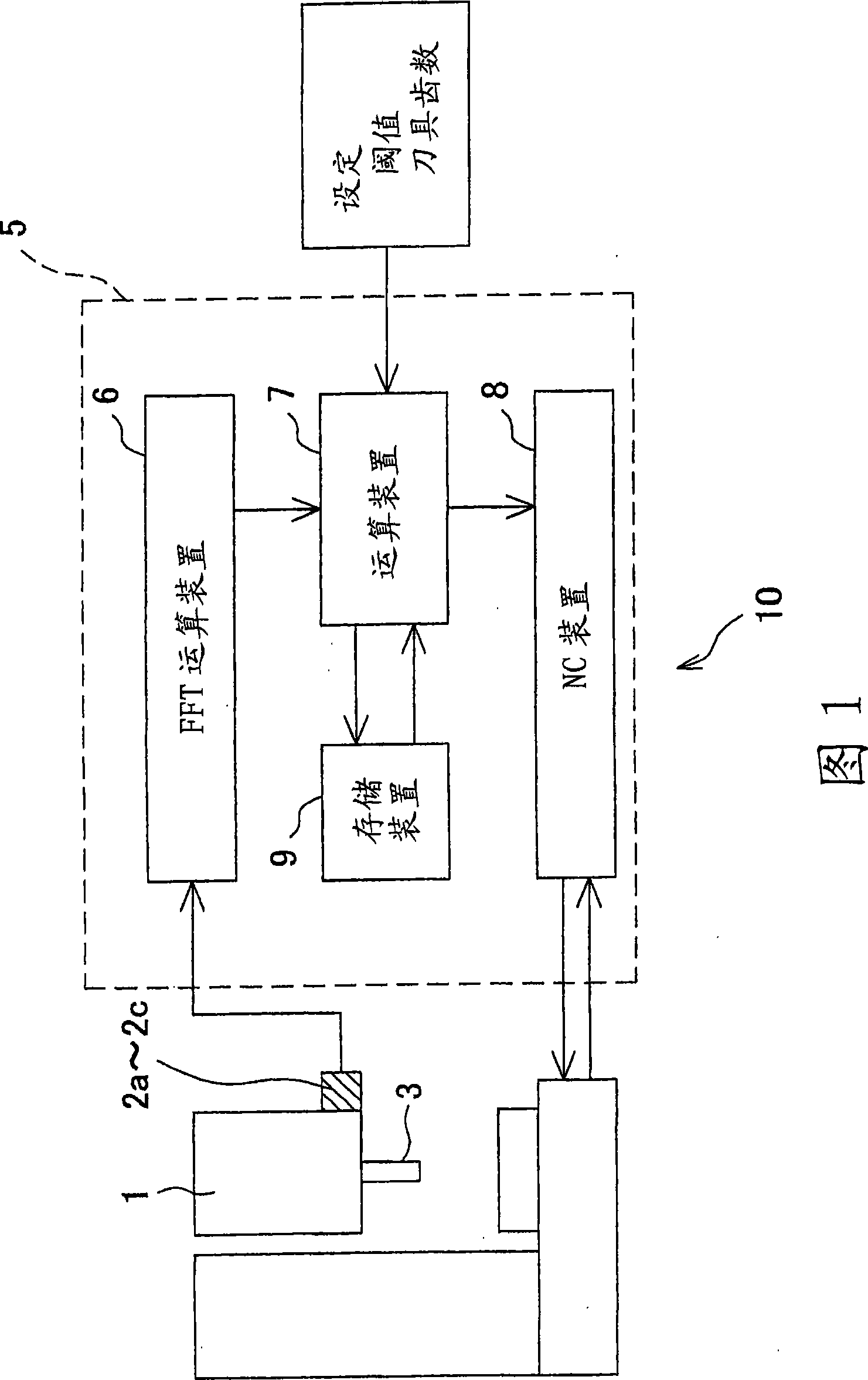

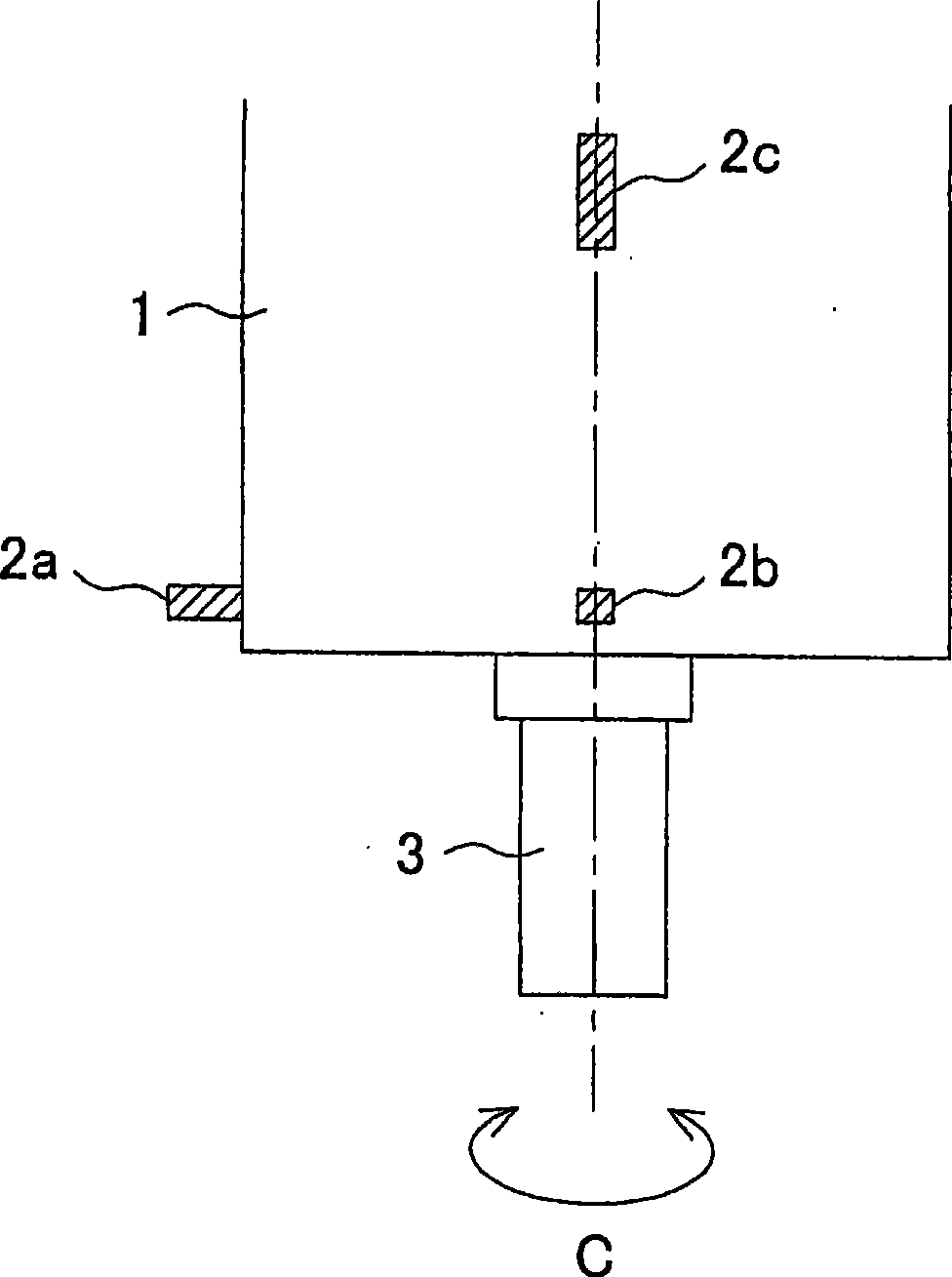

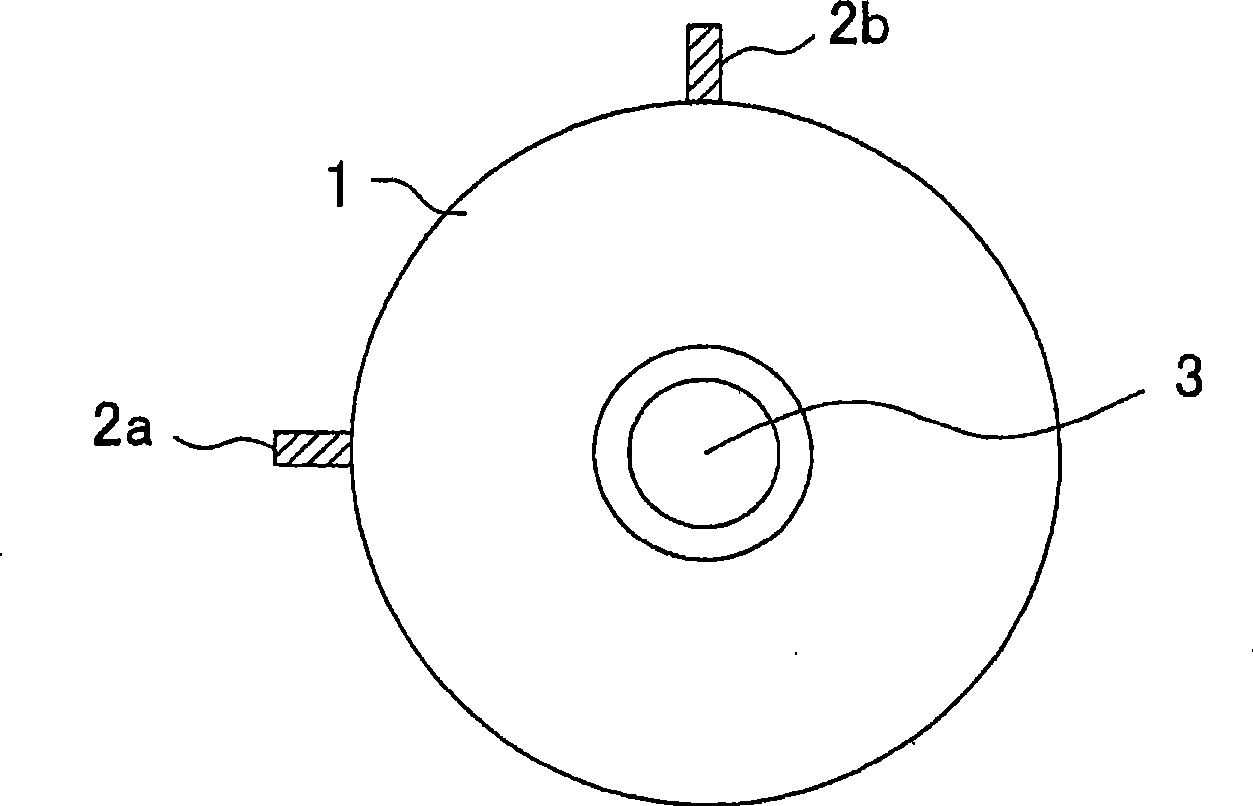

[0034] FIG. 1 is a schematic diagram showing a frame configuration of a vibration suppressing device 10 . figure 2 It is a schematic diagram showing the rotating shaft housing 1 to be subjected to vibration suppression from the side, image 3 It is a schematic diagram showing the rotating shaft housing 1 from the axial direction.

[0035] The vibration suppressing device 10 is used to suppress the "flutter" generated on the rotating shaft 3 that is provided in the rotating shaft housing 1 and can rotate along the C-axis system, by detecting the vibration acceleration of the time re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com