Solar energy film battery laser engraving device and method

A technology of solar thin film and laser etching, applied in laser welding equipment, welding equipment, metal processing equipment, etc., can solve the difficulty of installing the feeding and discharging conveying system, the difficulty of improving the air quality of the station, and the Y-axis motion system Long length and other problems, achieve the effect of automatic feeding and discharging, short length, and reduce labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

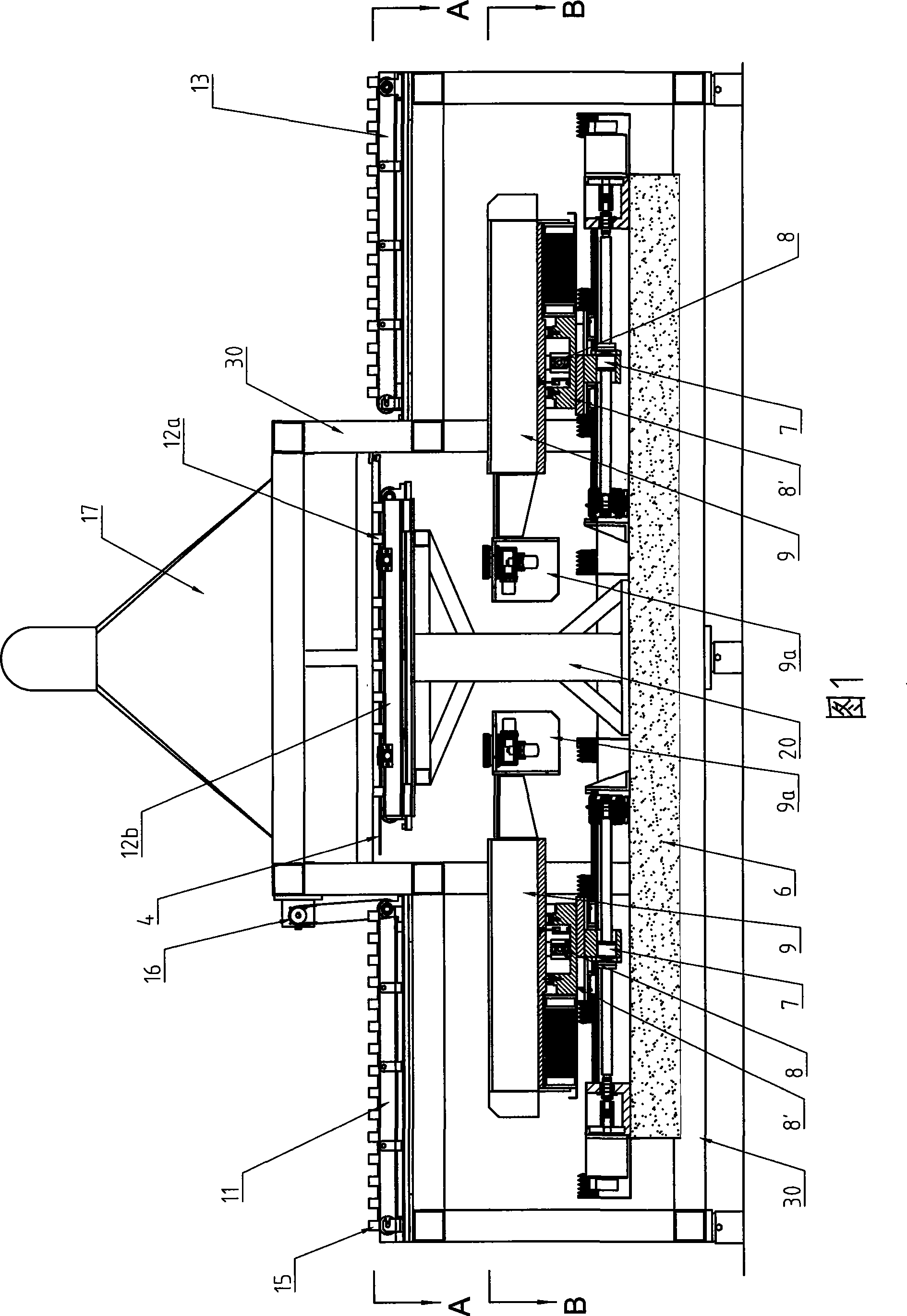

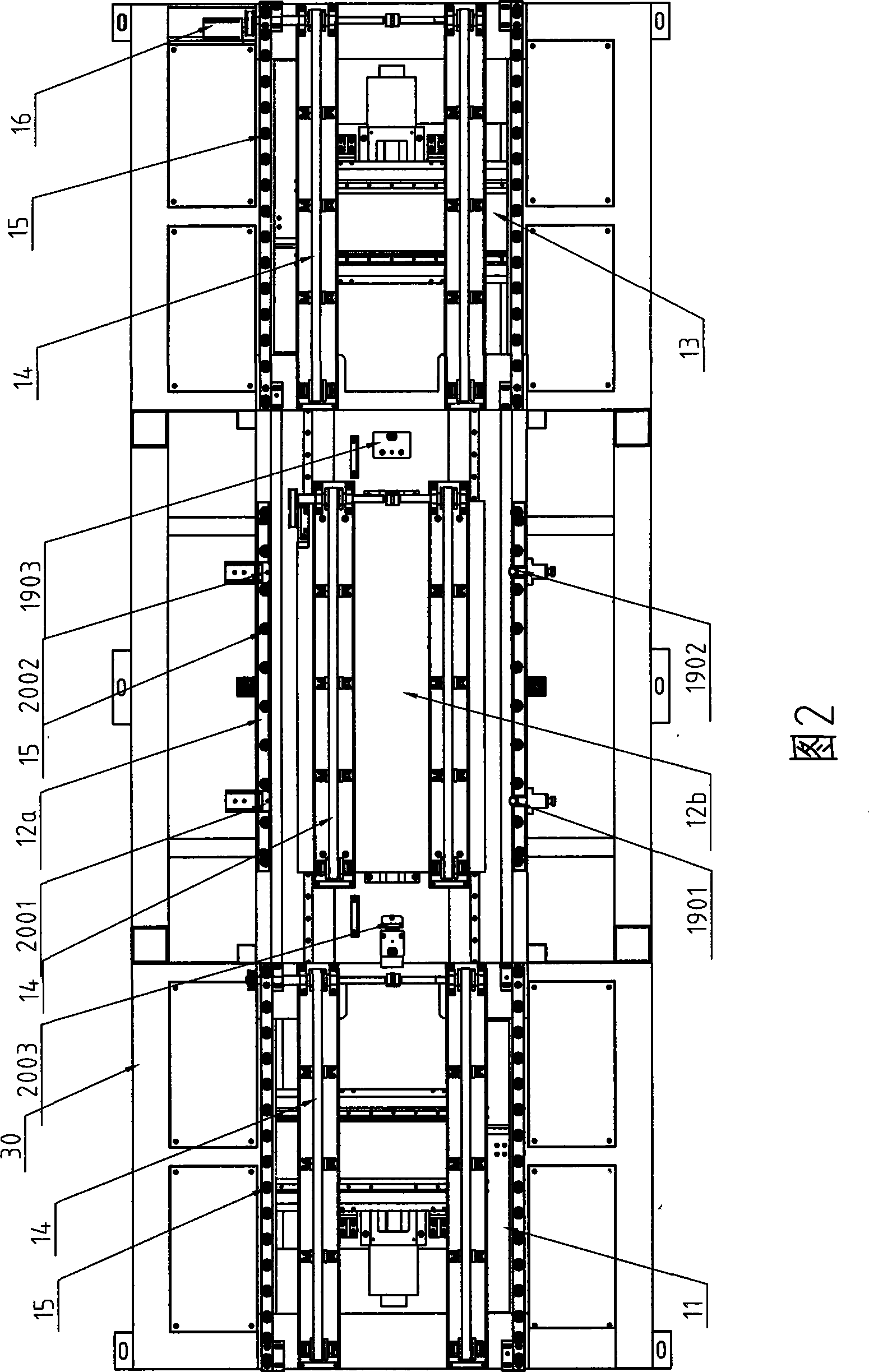

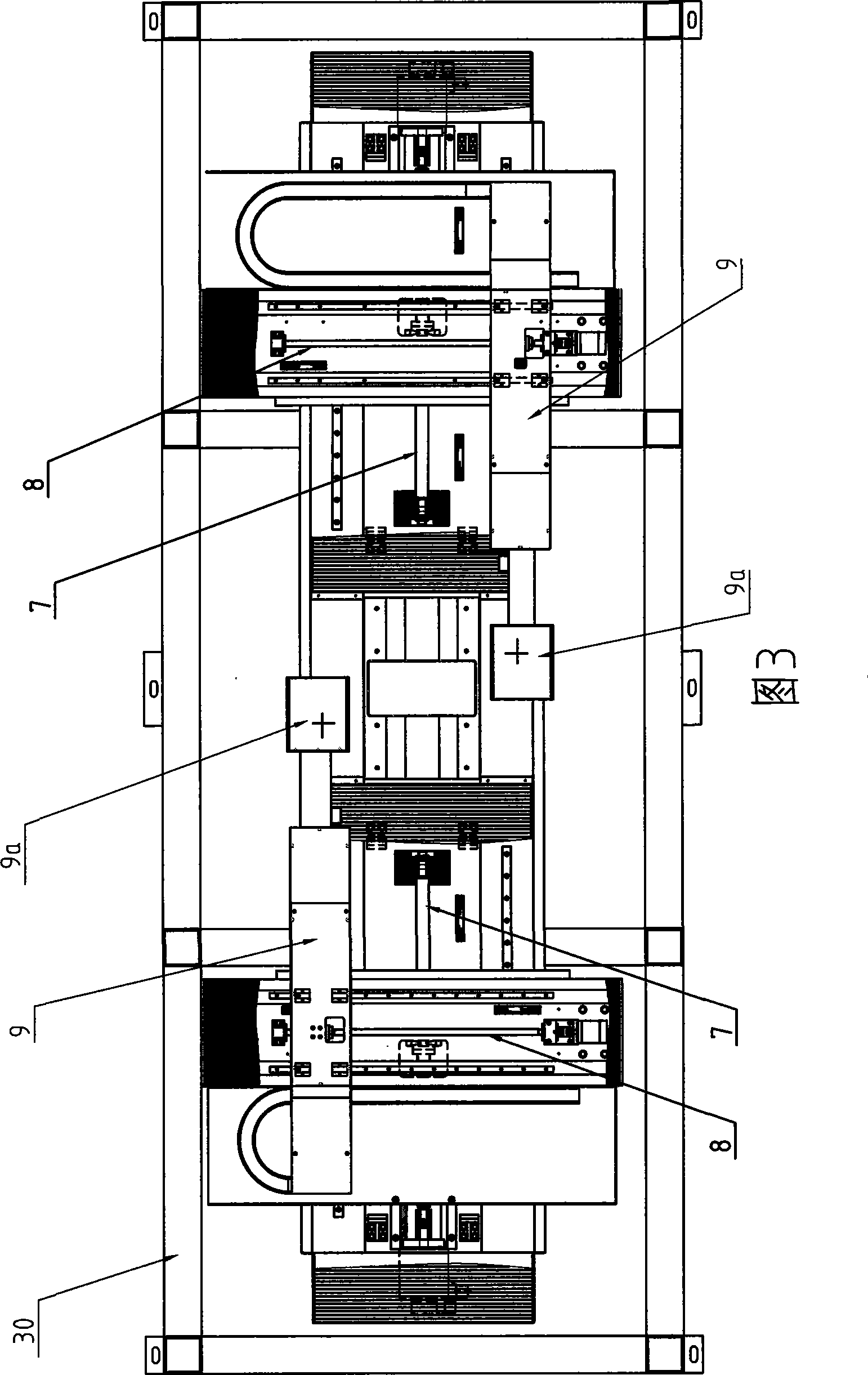

[0035] The laser etching equipment of the present invention is used to etch and remove the film on the edge of the amorphous silicon thin film solar cell, and the shaded part shown in FIG. 4 is the part to be etched on the edge of the amorphous silicon thin film solar cell.

[0036] As shown in FIGS. 1 to 8 , the embodiment of the laser etching equipment for solar thin film cells of the present invention includes a frame 30 , a marble Y-axis base 6 , and the marble Y-axis base 6 is installed on the frame 30 . Two sets of the same etching system are installed on the Y-axis base 6 , and the two sets of etching systems are arranged opposite to each other on the Y-axis base 6 . Each etching system has an X-axis motion system 8, an X-axis base 8', a Y-axis motion system 7 and a laser system 9. The X-axis motion system 8 is installed on the X-axis base 8', the X-axis base 8' is installed on the Y-axis motion system 7, and the Y-axis motion system 7 is installed on the Y-axis base 6 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com