Three-section LED lamp flip-chip production process

A production process, LED lamp technology, applied in lighting devices, lighting device parts, light sources, etc., can solve the problems of low production process efficiency and high cost, and achieve the effect of realizing assembly line operations, reducing material costs, and short length requirements.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] Specific embodiments of the present invention will be described below with reference to the accompanying drawings.

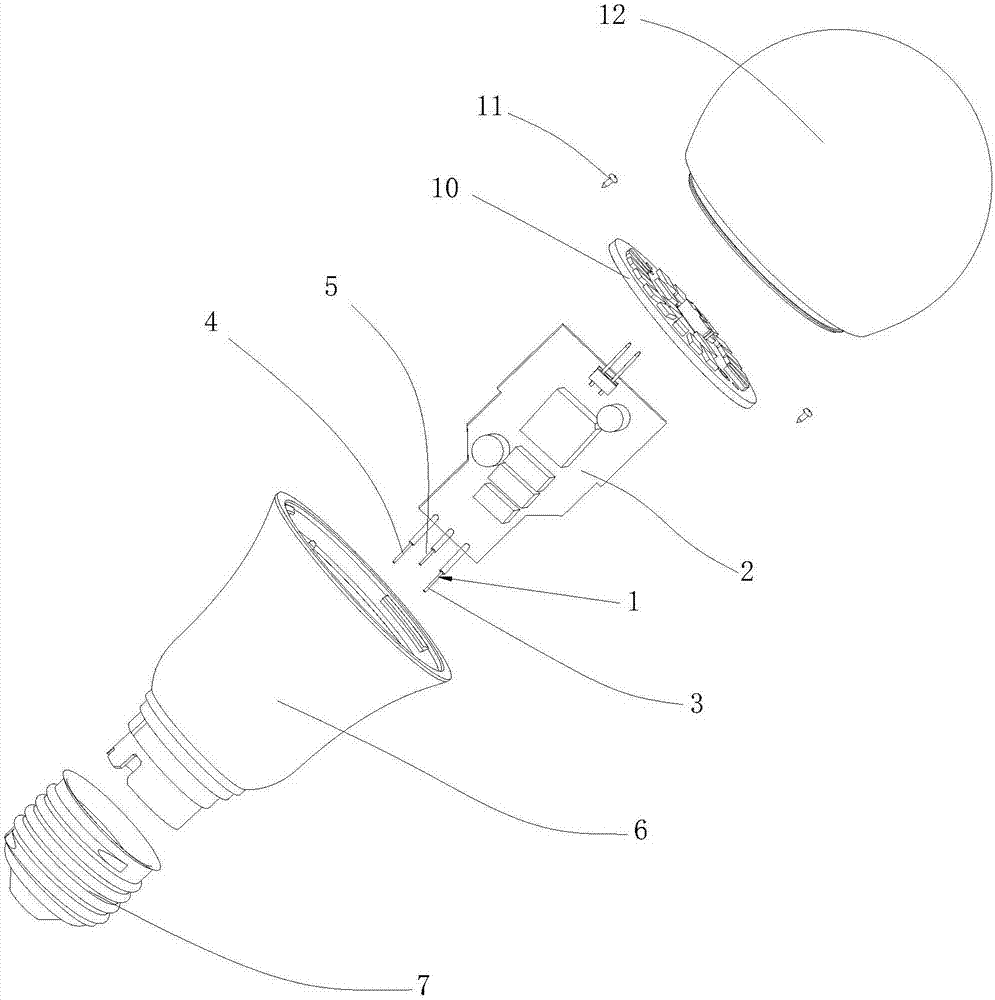

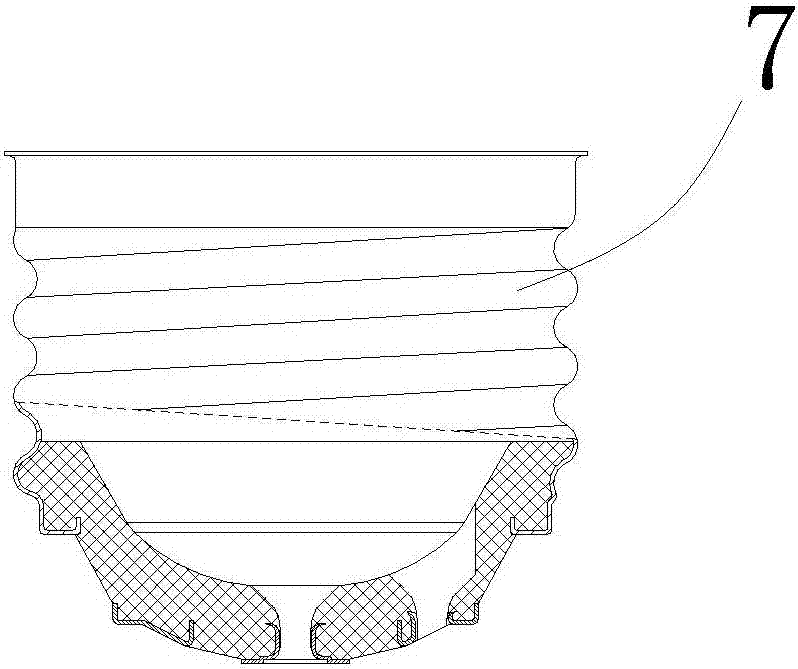

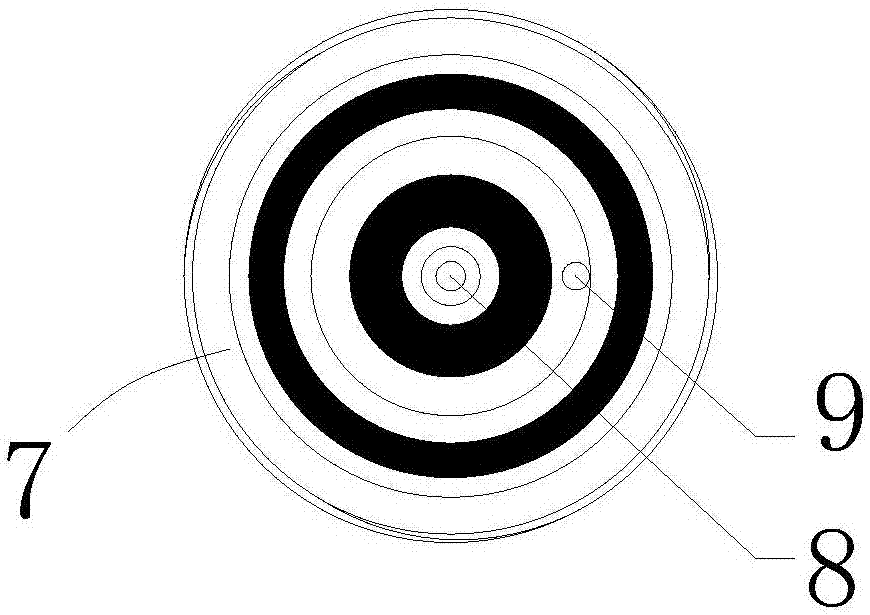

[0026] refer to figure 1 , figure 2 with image 3 , the structure of the three-section LED lamp of the present invention is as follows: it includes a three-section lamp cap 7, a lamp cup 6, a driving board 2, an LED light source assembly 10 and a bulb 12, and the driving board 2 is mounted on the lamp cup 6 Inside, the drive board 2 is provided with three power wires 1, the three-section lamp cap 7 is connected to the lamp cup 6, the three-stage lamp cap 7 is provided with a middle through hole 8 and an edge through hole 9, and the drive The board 2 is connected to the LED light source assembly 10 , and the upper bulb 12 is connected to the lamp cup 6 .

[0027] refer to figure 1 , figure 2 , image 3 with Figure 4 , a three-stage flip-chip production process for LED lamps, comprising the following steps in sequence:

[0028] a. Select three po...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com