Method and arrangement for producing an enlarged measurement volume for the purpose of determining the structure and/or winding speed of textile fibres on the basis of laser doppler anemometry

A Doppler velocimetry and velocity technology, which is applied to devices using optical methods, measuring devices, textiles and papermaking, etc., can solve the problems of expensive configuration of optical components, high sales costs, limited life, etc., and achieves simple and stable structure. Measuring, cost-saving effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

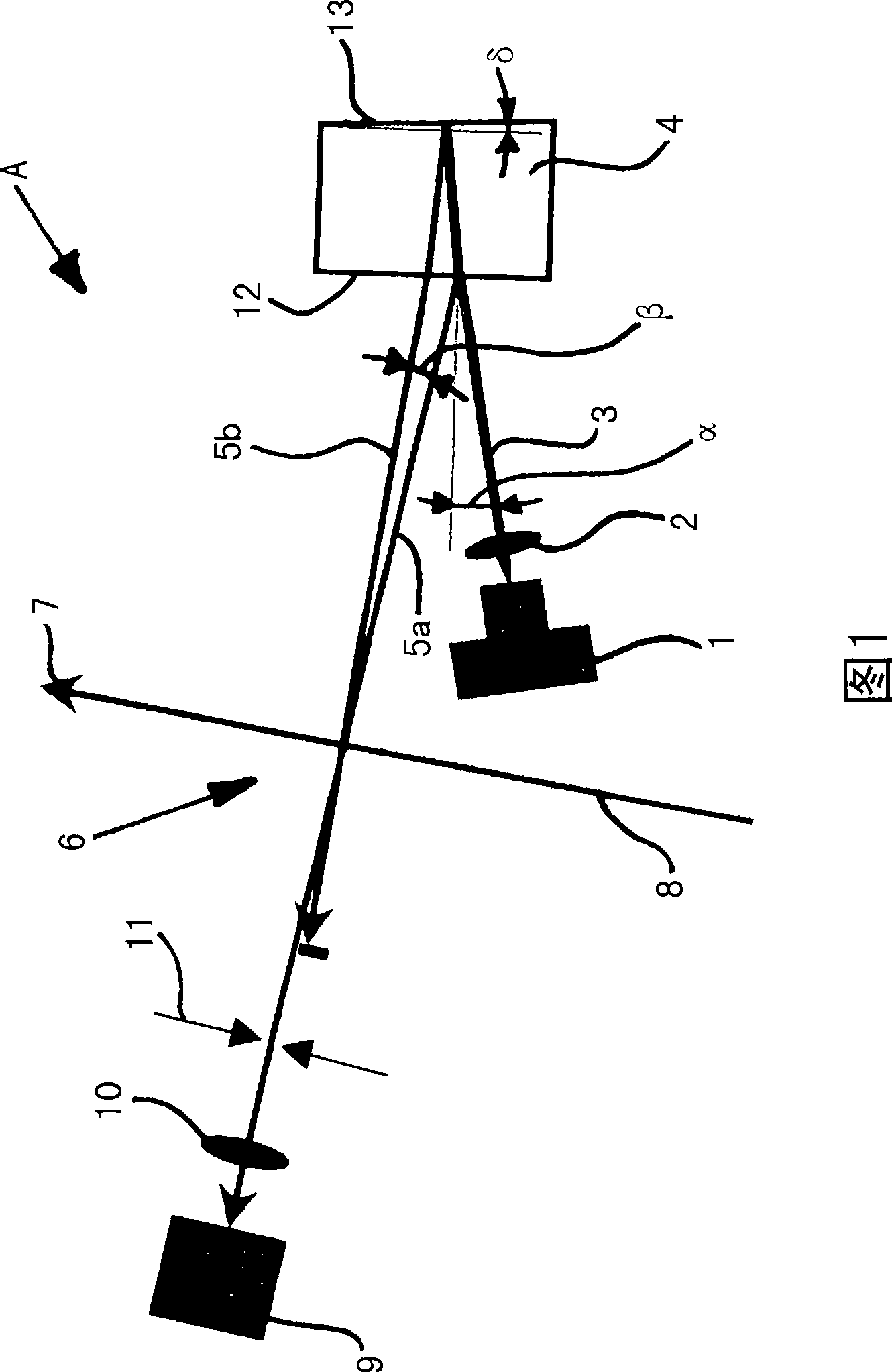

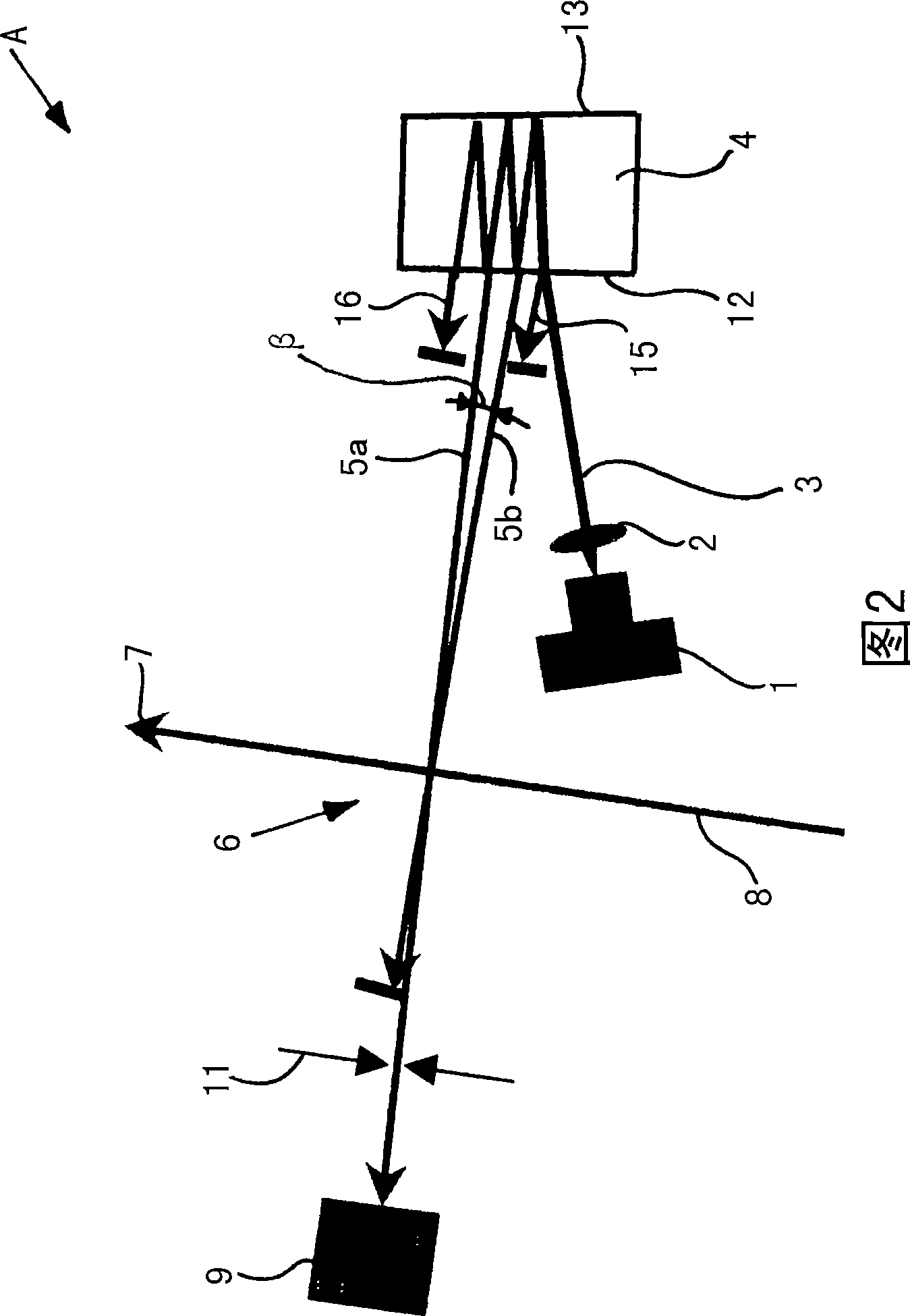

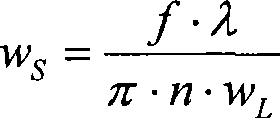

[0049] In the method shown in the figures, the diode laser 1 is implemented as a light source connected to a collimating lens 2 . The laser beam 3 generated by the light source is directed with a constant beam diameter to a wedge-shaped prism 4, which is implemented as a beam-splitting and guiding device. By means of a monolithic wedge prism 4, the laser beam 3 is divided into two sub-beams 5a and 5b according to the following method, the sub-beams 5a and 5b are directed towards a thread 8 which runs in the direction of the arrow 7 through the thread of a textile machine (not shown in detail) position 6. Here, thread position 6 is the spool position of the textile machine. In the area opposite the wedge prism 4 with respect to the textile yarn or thread 8 there is a photodetector 9 serving as a light sensor device and a receiver lens which may in particular comprise a converging lens 10 and / or a hole 11 .

[0050] As shown in the figures of the present method, the wedge-sha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com