Ion cleaning gun for eliminating electricity and dust

A cleaning gun and electrostatic precipitator technology, applied in the direction of electrostatic cleaning, static electricity, electrical components, etc., can solve problems such as operation failure, equipment performance degradation, and poor ion balance performance, so as to ensure insulation performance and reduce use failures , the effect of prolonging the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

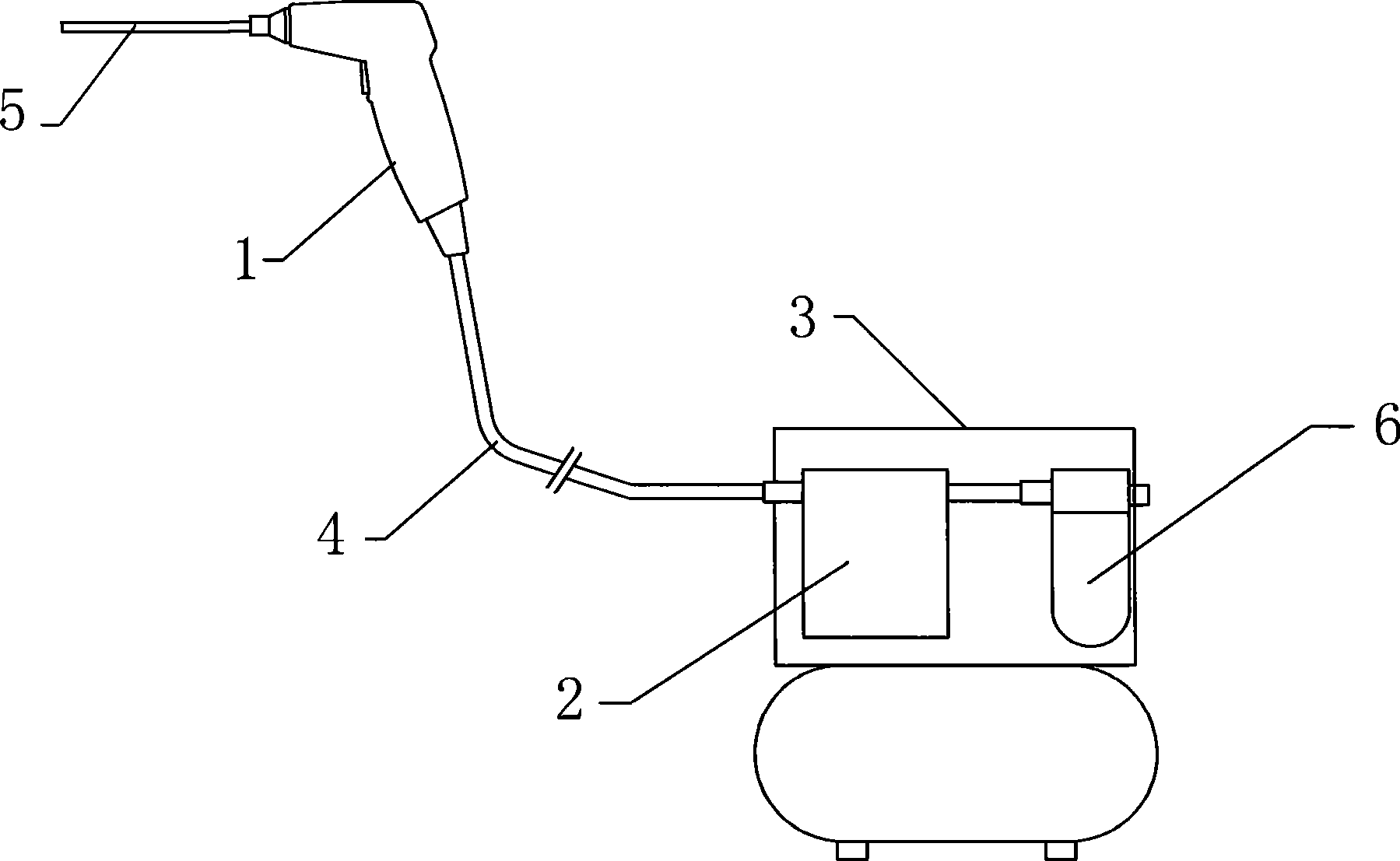

[0020] Such as figure 1 As shown, the present invention is an ion cleaning gun for static electricity and dust removal, and the ion cleaning gun is composed of an ion air gun 1, an ion air gun controller 2 and an air compression pump 3, and the ion air gun is electrically connected to the controller , the ion air gun is connected through the connecting pipeline 4 and the air compressor pump.

[0021] The top of the ion air gun is a nozzle part, and an insulating thin tube 5 is installed on the nozzle part.

[0022] The ion spray gun has a built-in small high-voltage power supply, and the output end of the high-voltage power supply is connected with a discharge needle.

[0023] The controller has a built-in solenoid valve and a power supply for the ion air gun, and the output end of the power supply for the ion air gun is electrically connected to the input end of the built-in small high-voltage power supply of the ion air gun.

[0024] Described air compression pump is equip...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com