Method for detecting equipment parameter filtrating chip conical defect through regulating detect

A technology for equipment parameter and defect inspection, which is applied in the direction of optical test defect/defect, semiconductor/solid-state device test/measurement, etc., can solve problems such as difficult-to-filter cone-shaped defects, affect the accuracy of scanning detection effect, etc., and achieve improved scanning effect Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] Describe in detail below in conjunction with accompanying drawing.

[0041] The scanning device used in this article is a defect inspection device named AIT (advanced inspection technoLogy) produced by KLA-Tencor.

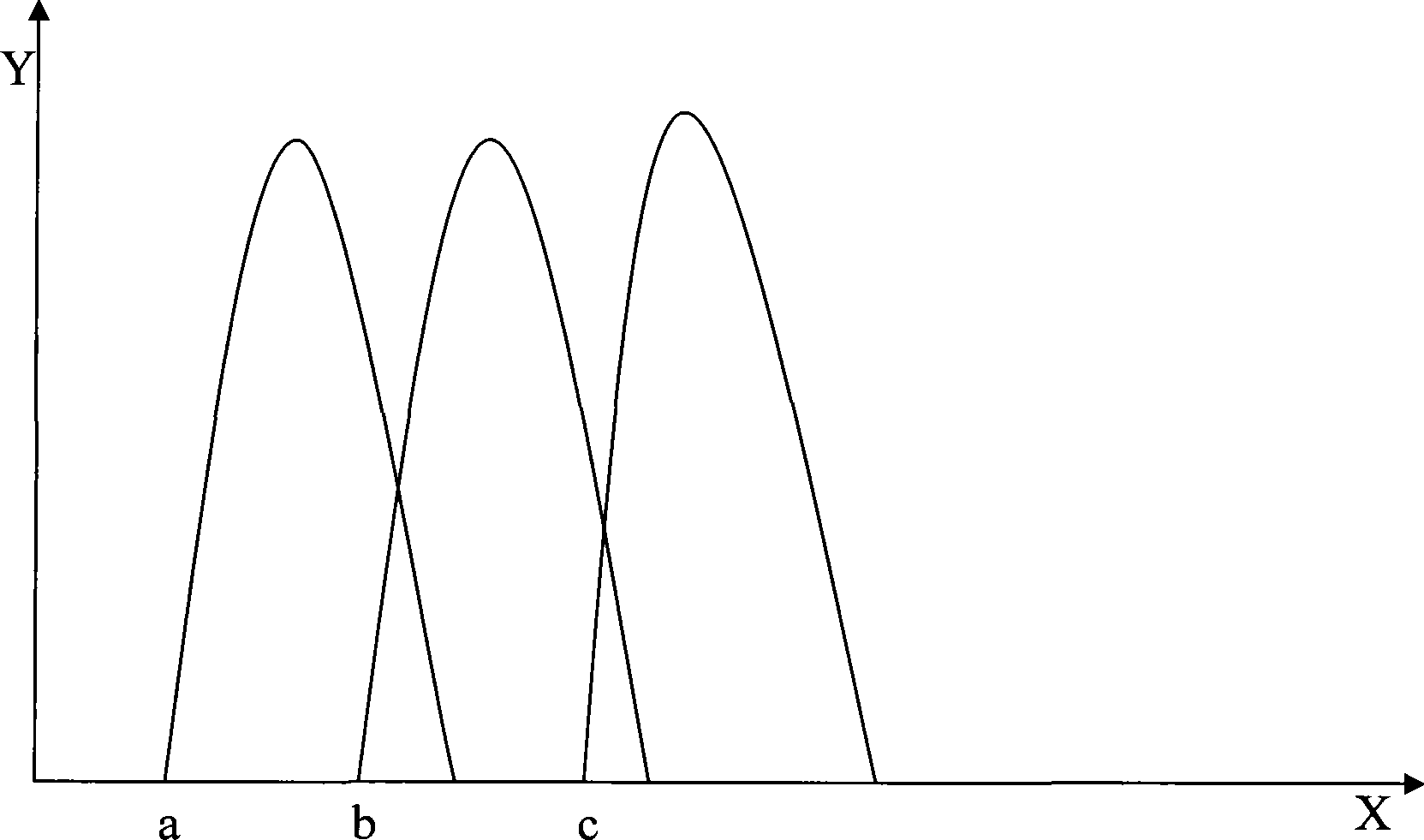

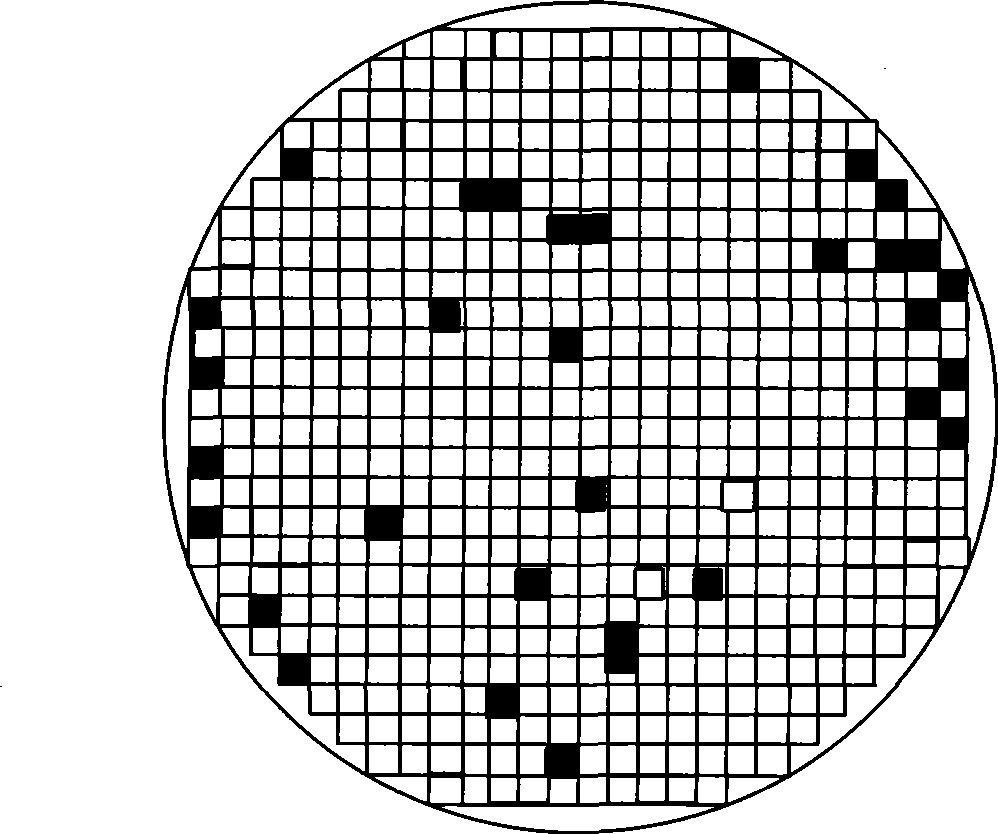

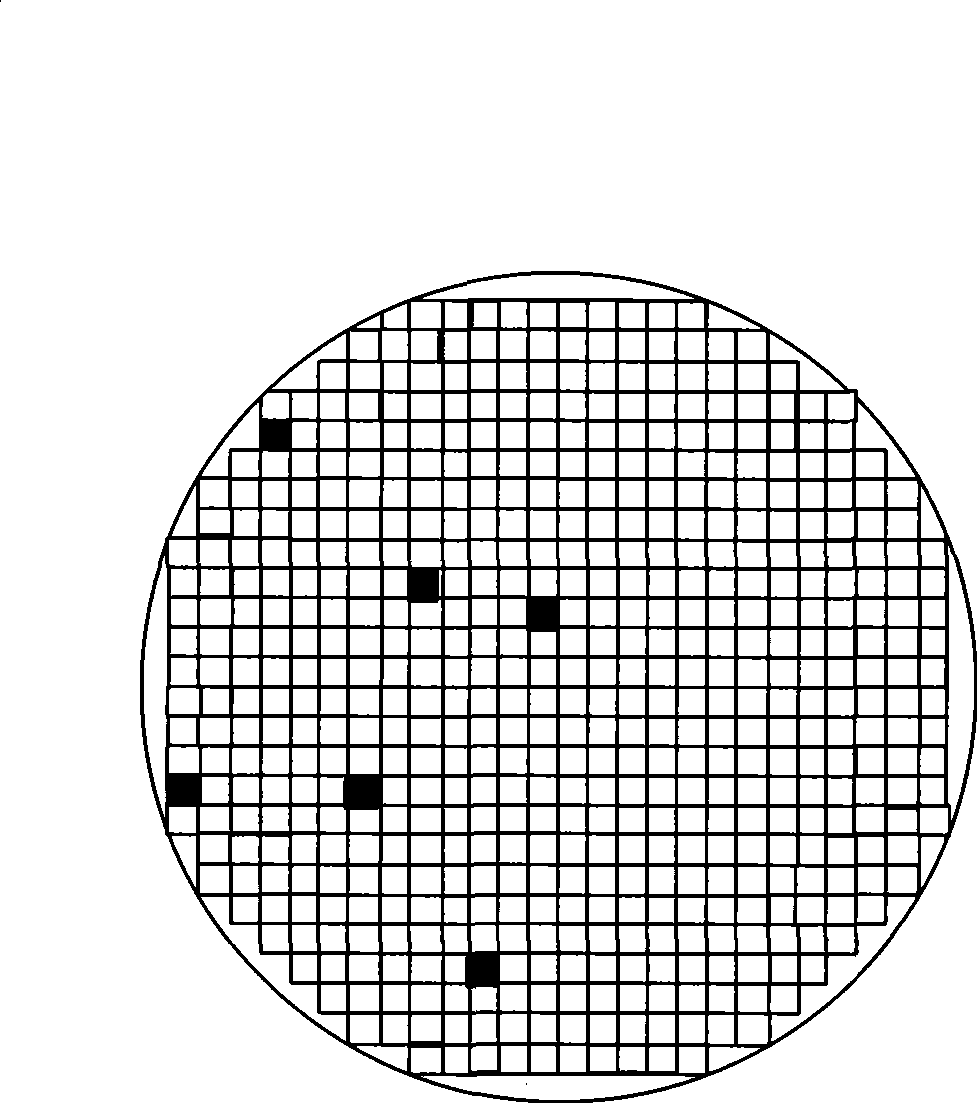

[0042] A method for filtering chip cone-shaped defects by adjusting defect inspection equipment parameters, the three parameters of Lo are the voltage values of three dynamic scattering receivers, comprising the following steps:

[0043] A, Adjust the three values of the scanning device machine system parameter Lo between the system default value and 0 for a given polarization combination.

[0044] Lo is one of the system parameters of the scanning device, which has three values, and the wind corresponds to the three dynamic scattering receivers of the scanning device. These three values are used to adjust the voltages of the three receiving devices, which determine the intensity of the received laser light scattering. Low voltage values make these...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com