Method for measuring electrode current of buried arc furnace

A technology of electric furnace electrode and measurement method, which is applied in the direction of measuring device, measuring electric variable, measuring current/voltage, etc., can solve the problems of open flame, large smoke and dust, and unsuitable installation of detection equipment, etc., and achieves high accuracy, low cost, and measurement Method reliable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The technical solutions of the present invention will be described in further detail below with reference to the accompanying drawings and embodiments.

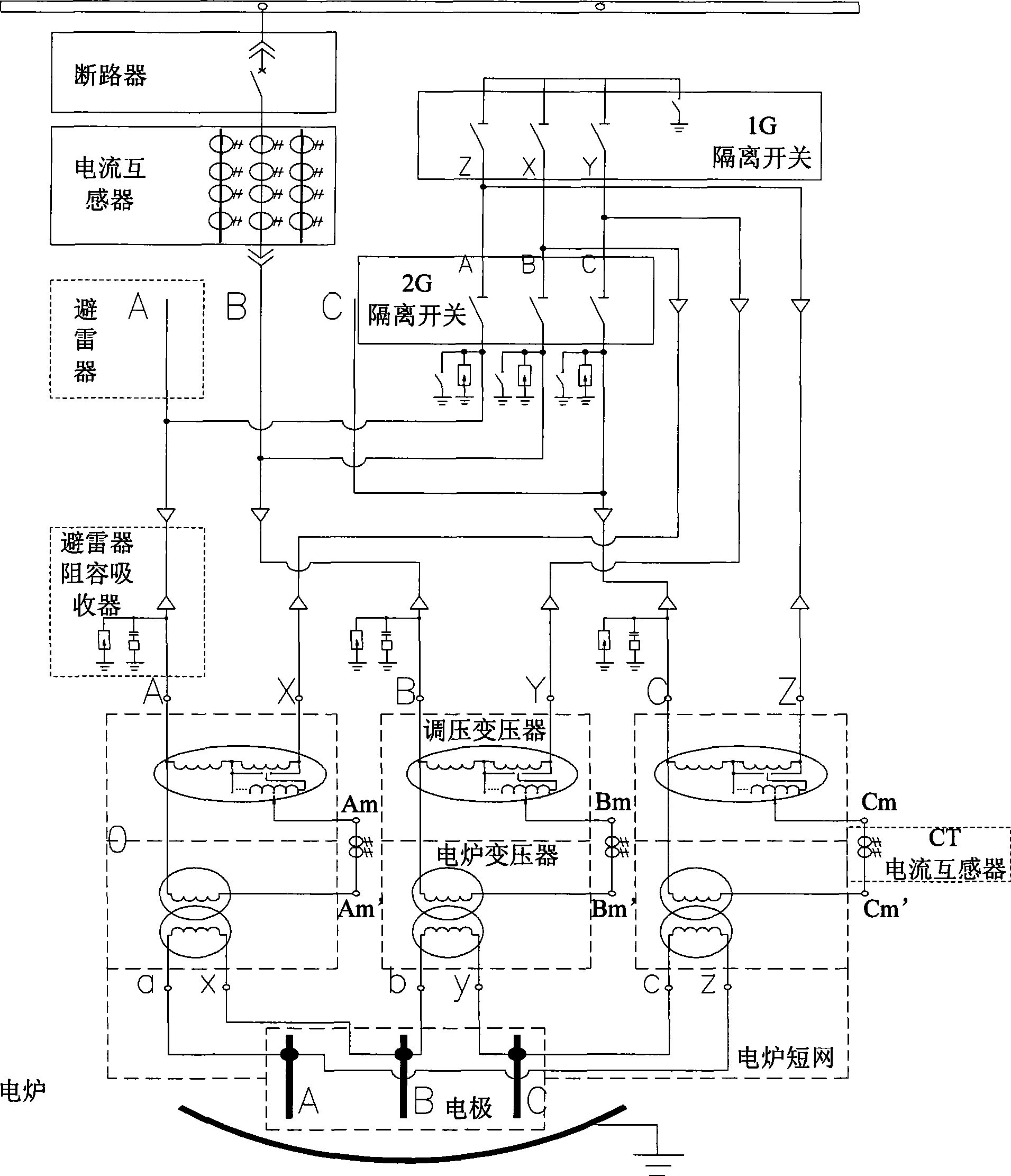

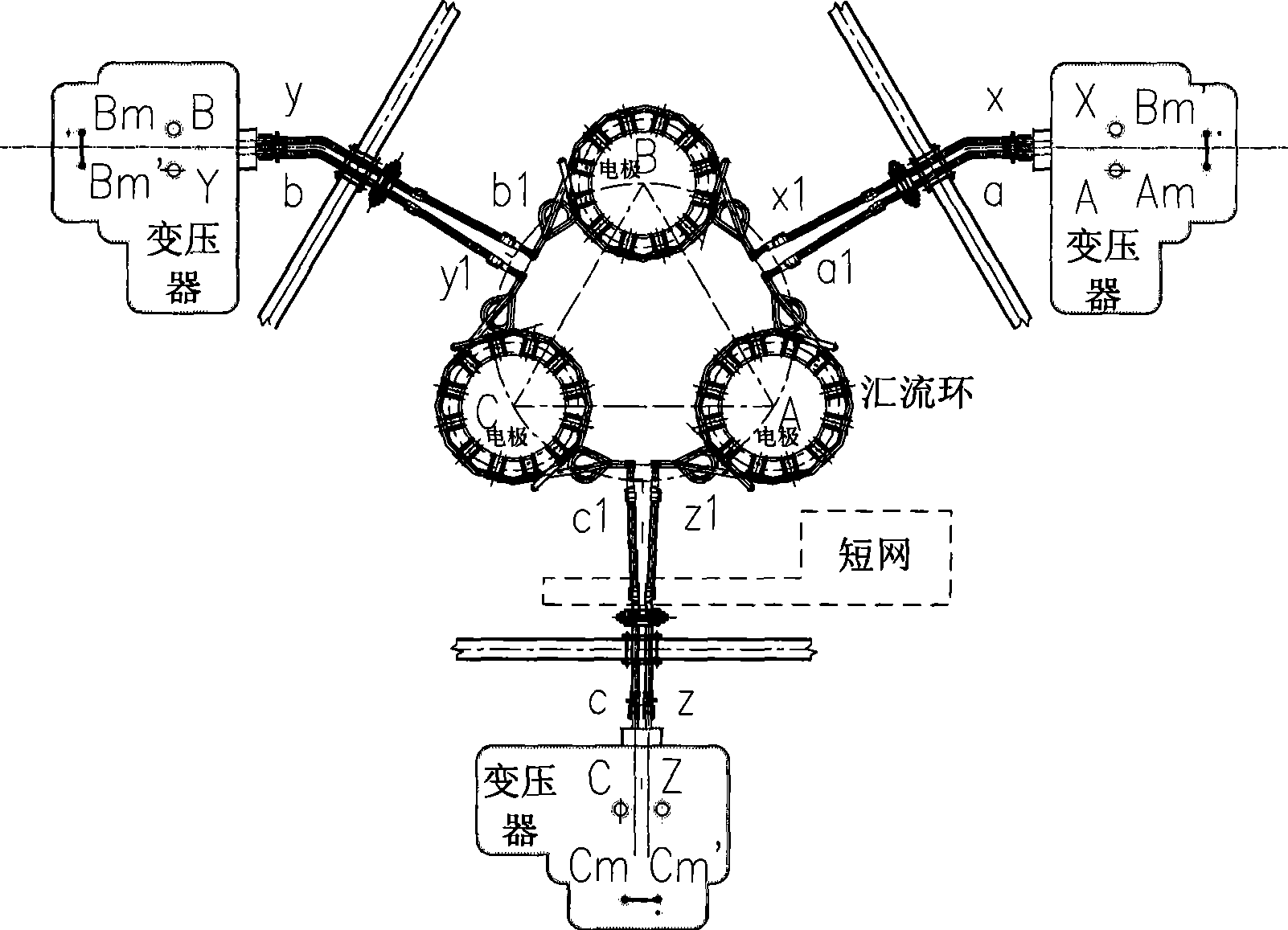

[0032] The current measurement method of the submerged arc furnace electrode in the prior art mainly focuses on the main circuit of the electric furnace. Since the short network current of the electric furnace is connected with the secondary current of the electric furnace transformer, the internal structure of the electric furnace transformer can be used to measure the electrode current of the submerged arc electric furnace. Measurement.

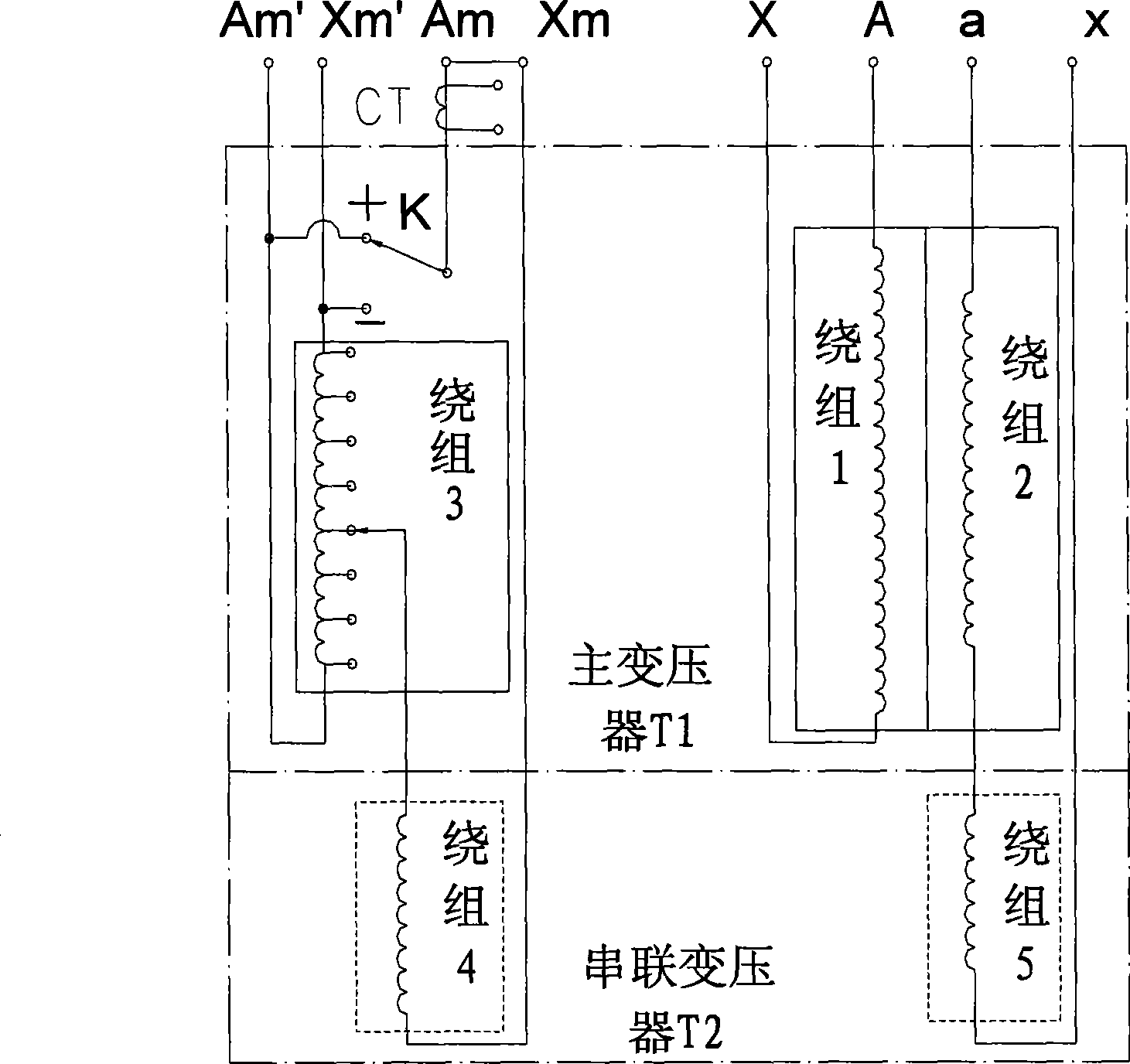

[0033] Large-scale electric furnace transformers are divided into two main methods according to the voltage regulation method: the on-load voltage regulation method of the series transformer and the on-load voltage regulation method of the autotransformer, such as Figure 3A and Figure 3B Shown is a schematic diagram of the existing pressure regulation method.

[0034] Refer to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com