Soft steel shearing lag return damper

A damper and hysteresis technology, applied to building components, earthquake resistance, etc., can solve problems such as high maintenance costs, and achieve the effects of small space occupation, avoiding local buckling, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

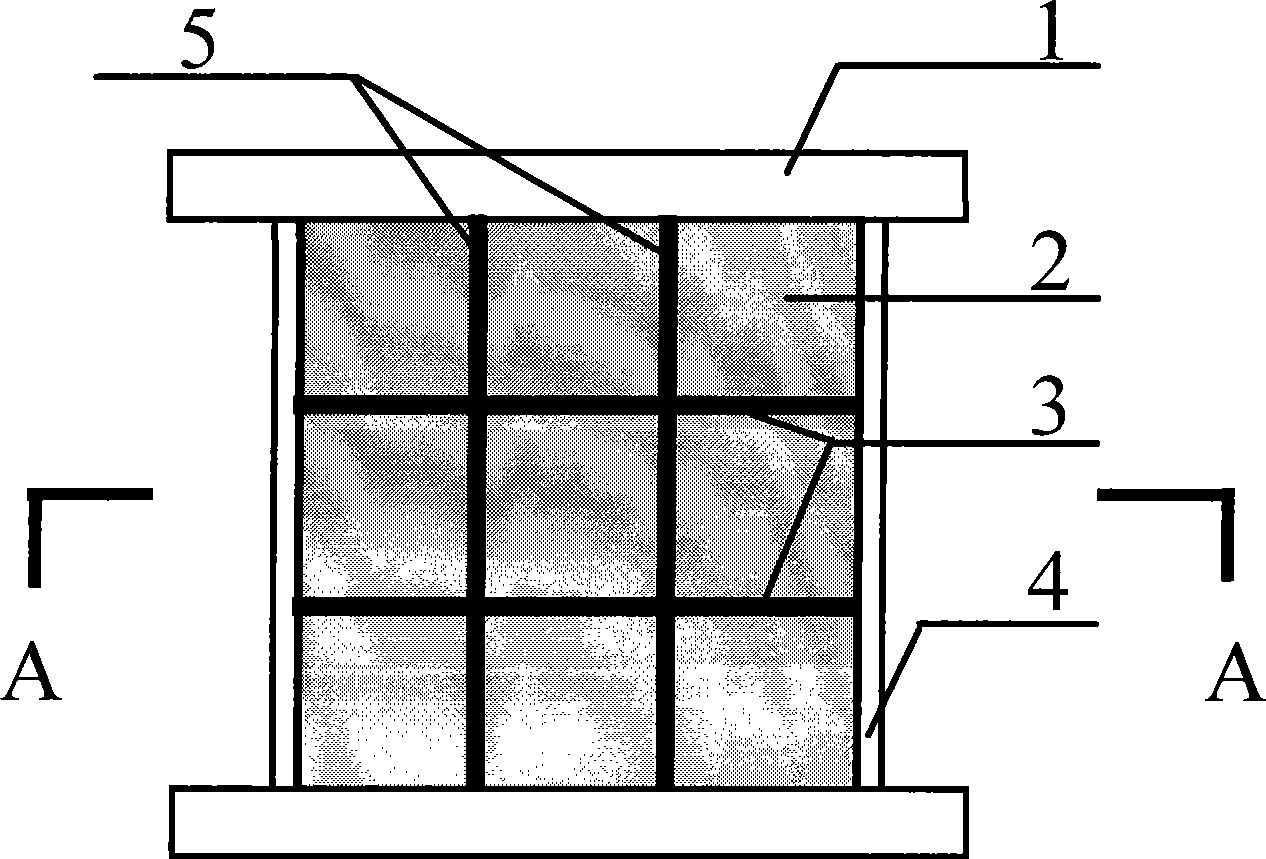

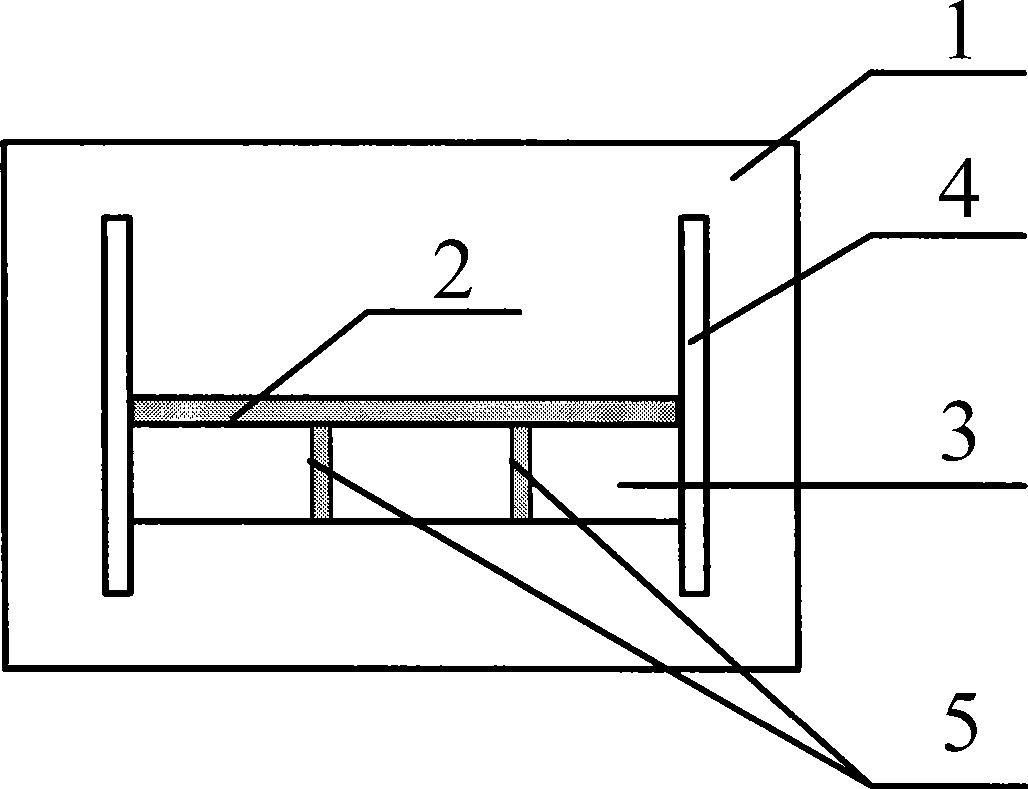

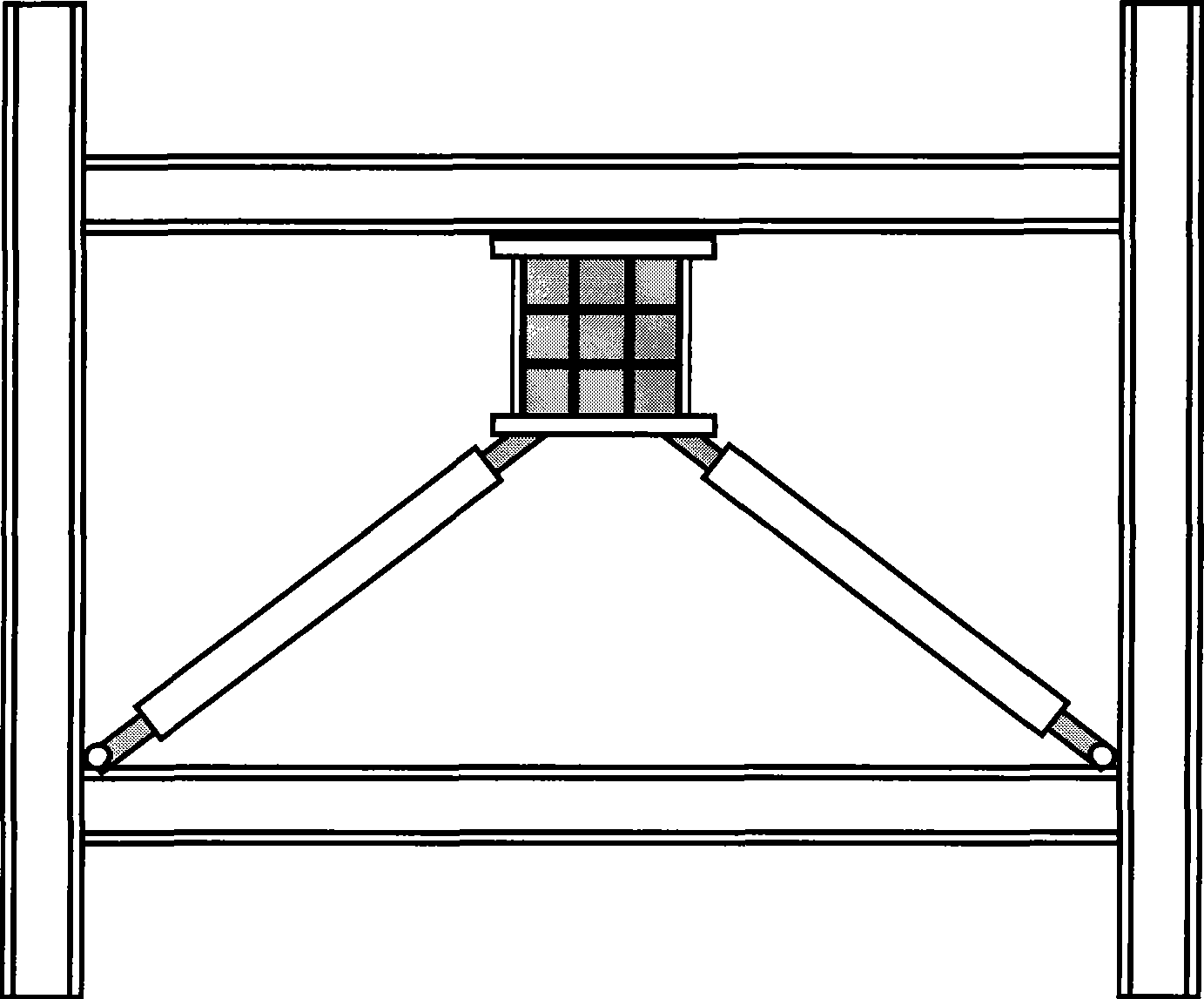

[0014] The content of the present invention is described below in conjunction with embodiment. Such as figure 1 Shown, is the main part of the mild steel shear hysteretic damper of the present invention, namely image 3 with Figure 4 Parts shown in shaded.

[0015] The damper of the present invention comprises: a rigid connecting plate 1 , a hysteretic energy dissipation web 2 , a transverse stiffener 3 , a flange 4 and a longitudinal stiffener 5 . Among them, the hysteretic energy-dissipating web 2 is the main energy-dissipating plate, and the rigid connecting plate 1 and the flange 4 are welded around it. When there are reliable edge constraints around the hysteretic energy dissipation web 2 (such as Figure 4 example shown), such rigid connecting plates 1 and flanges 4 can be omitted. The transverse stiffener 3 and the longitudinal stiffener 5 can be welded on one side or both sides of the hysteretic energy dissipation web 2 . When the softness ratio parameters of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com