Method for preparing near-infrared concealed cotton textiles

A cotton textile and near-infrared technology, which is applied in the field of preparation of infrared stealth cotton textiles, can solve problems affecting the wearing comfort of the human body, poor bonding fastness between paint and fabric, poor abrasion resistance, etc., and achieve good color fastness and breathability Sexy and comfortable to wear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

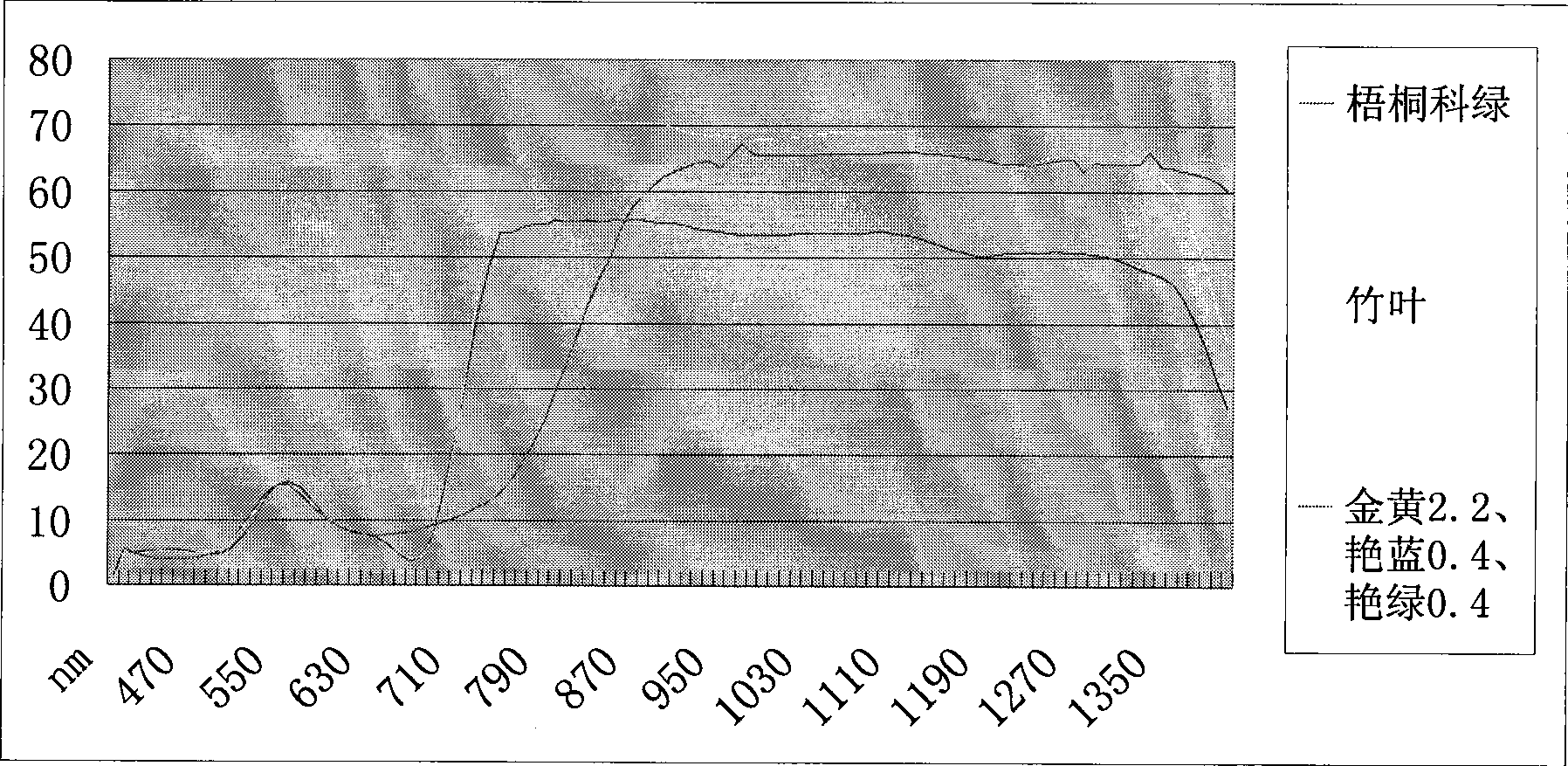

[0030] Weigh 2.2% of reduced golden yellow RK, 0.4% of reduced brilliant blue RCL, and 0.4% of reduced brilliant green FFB into a clean Erlenmeyer flask A. Restore with a dry cylinder method, dilute with a small amount of distilled water (5ml), add 2 / 3 of the amount of caustic soda (NaOH) and sodium bicarbonate (NaOH) 2 S 2 o 4 ), add water to make the dye bath 1 / 4 of the total amount of the dye solution, and stir. Take another clean Erlenmeyer flask B, add 3 / 4 of the total amount of distilled water required and the remaining 1 / 3 of the amount of caustic soda. Put the two Erlenmeyer flasks into a constant temperature water bath at the same time, raise the temperature to 60°C, and fully reduce the dye for 8-10 minutes to make a leuco dye solution. Then add the remaining 1 / 3 amount of hydrosulfite into conical flask B to fully dissolve, then add it into the dye solution (conical flask A) that has been dried and reduced, and stir evenly.

[0031] After the vat dye leuco dyein...

Embodiment 2

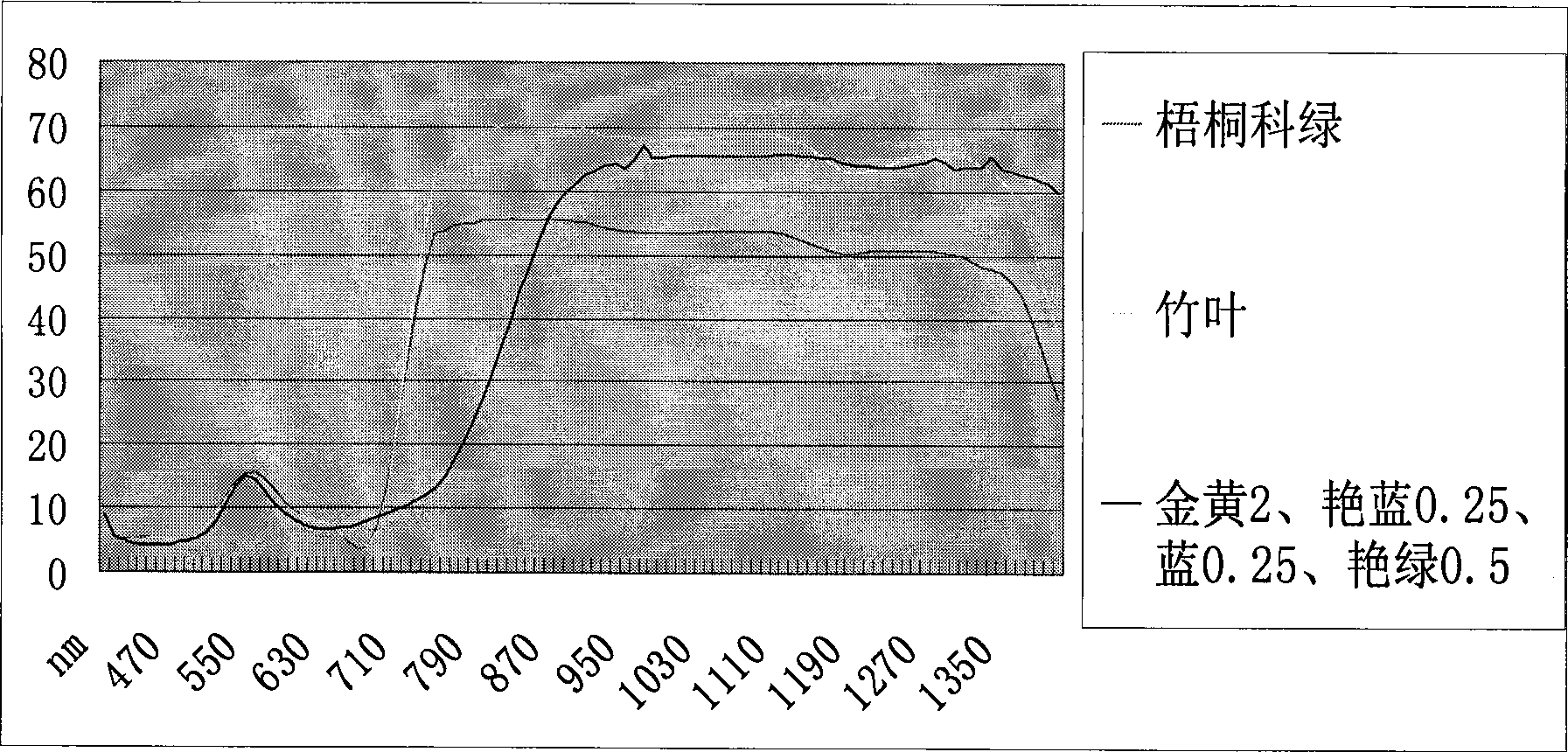

[0034] Weigh reduced golden yellow RK 2%, reduced brilliant blue RCL 0.25%, reduced brilliant blue BC 0.25%, reduced brilliant green FFB 0.5% in a clean Erlenmeyer flask A. Restore with a dry cylinder method, dilute with a small amount of distilled water (5ml), add 2 / 3 of caustic soda, sodium hydrosulfite, and add water to make the dye bath 1 / 4 of the total amount of the dye solution, and stir evenly. Take another clean Erlenmeyer flask B, add 3 / 4 of the total amount of distilled water required and the remaining 1 / 3 of the amount of caustic soda. Put the two Erlenmeyer flasks into a constant temperature water bath at the same time, raise the temperature to 60°C, and fully reduce the dye for 8-10 minutes to make a leuco dye solution. Then the remaining 1 / 3 amount of hydrosulfite (Na 2 S 2 o 4 ) into the Erlenmeyer flask B to fully dissolve, and then add it into the dried and reduced dye solution (Elenmeyer flask A), and stir evenly.

[0035] After the vat dye leuco dyeing b...

Embodiment 3

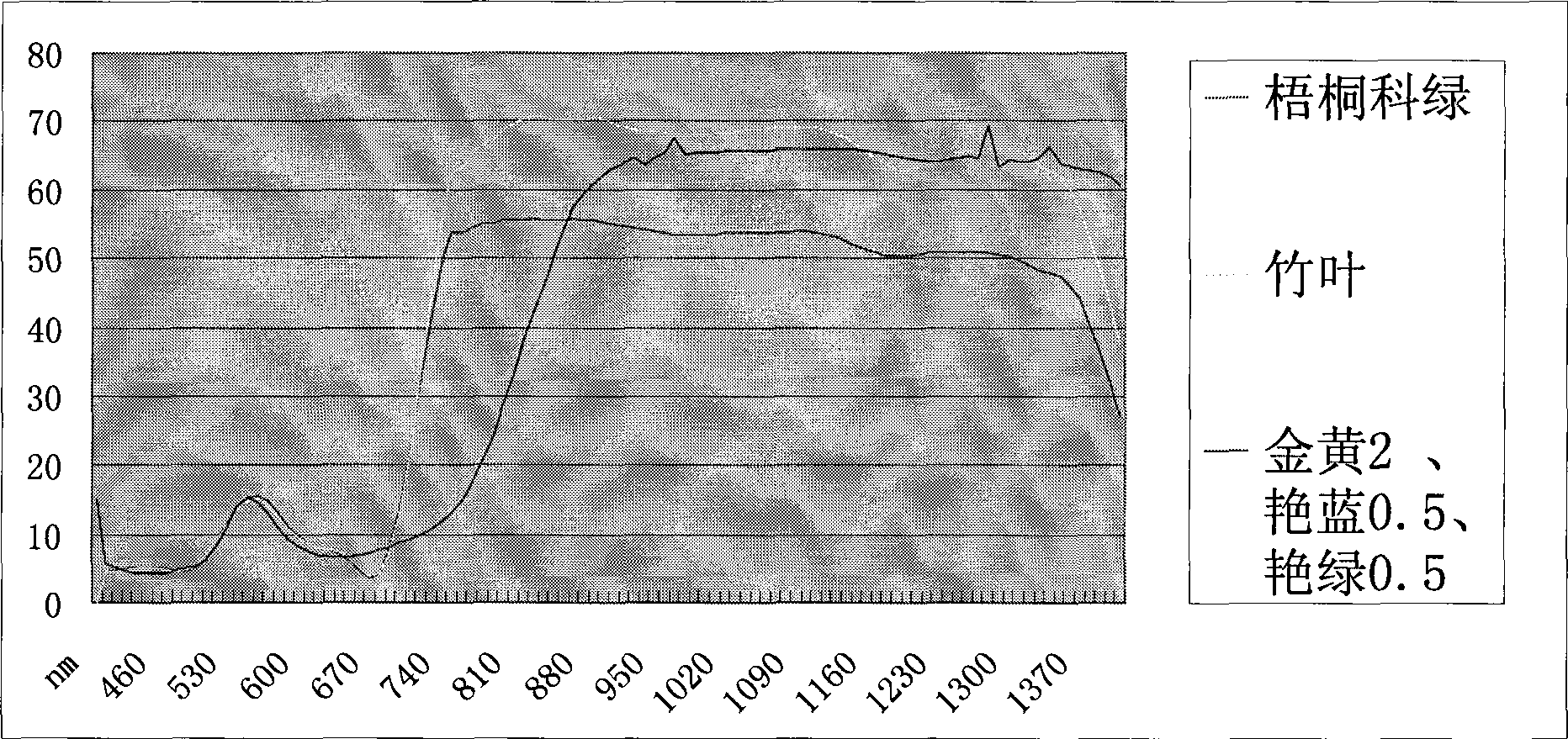

[0038] Weigh 2% of reduced golden yellow RK, 0.5% of reduced brilliant blue RCL, and 0.5% of reduced brilliant green FFB into a clean Erlenmeyer flask A. Restore with a dry cylinder method, dilute with a small amount of distilled water (5ml), add 2 / 3 of the amount of caustic soda (NaOH) and sodium bicarbonate (NaOH) 2 S 2 o 4 ), add water to make the dye bath 1 / 4 of the total amount of the dye solution, and stir. Take another clean Erlenmeyer flask B, add 3 / 4 of the total amount of distilled water required and the remaining 1 / 3 of the amount of caustic soda. Put the two Erlenmeyer flasks into a constant temperature water bath at the same time, raise the temperature to 60°C, and fully reduce the dye for 8-10 minutes to make a leuco dye solution. Then add the remaining 1 / 3 amount of hydrosulfite into conical flask B to fully dissolve, then add it into the dye solution (conical flask A) that has been dried and reduced, and stir evenly.

[0039] After the vat dye leuco dyeing ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com