Heat resisting polyimides / polyhedral oligomeric silsesquioxane nano hybridization material

A technology of polysilsesquioxane and nano-hybrid materials is applied in the field of materials, which can solve the problems that the performance of pure polyimide cannot meet the requirements, and achieve the effects of improving performance, improving thermal performance and broad application prospects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

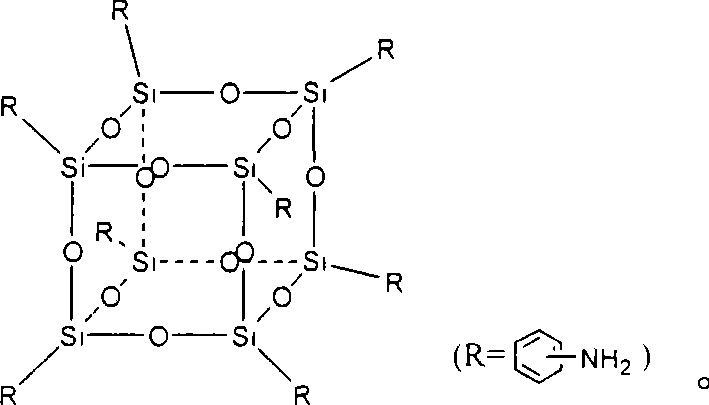

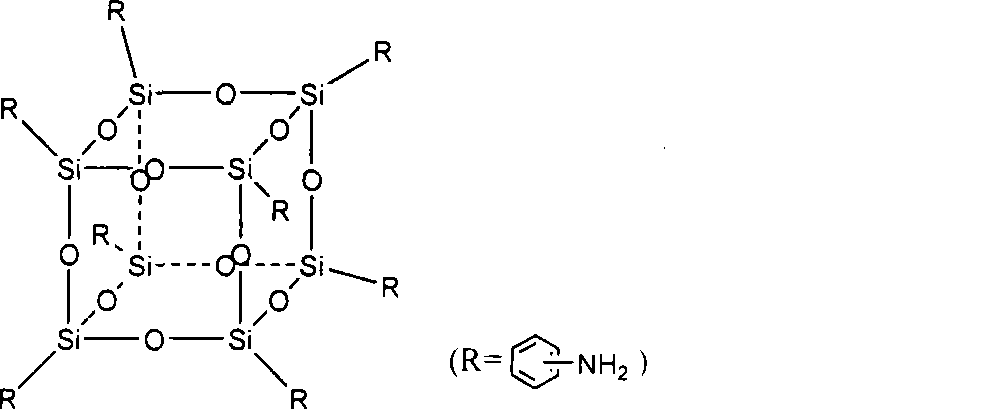

[0037]Dissolve 1.3g of octaaminophenylsilsesquioxane (OAPS for short) in 15ml of N-methylpyrrolidone (NMP for short). After fully dissolving, slowly drop into 10ml of A NMP solution of 2.9 g of benzophenonetetracarboxylic dianhydride (BTDA); after the dropwise addition, react at 30° C. for 1 hour under a nitrogen atmosphere to obtain a polyhedral oligomeric silsesquioxane solution with an anhydride functional group;

[0038] Take 2.0g of 4,4'-diaminodiphenyl ether (ODA) monomer and dissolve it in 30ml of NMP. After fully dissolving, add 1.0ml of the polyhedral oligomeric silsesquioxane solution with anhydride functional groups dropwise; Then add 3.2g BTDA, and the feeding time is controlled at 60 minutes. After the feeding is completed, react at 20°C for 20 hours under a nitrogen atmosphere to obtain a uniform polyamic acid solution with a solid content of 0.18g / ml;

[0039] The above polyamic acid solution was formed into a film on a glass plate, and imidization treatment was...

Embodiment 2

[0041] According to the method of Example 1, the amount of ODA and additional BTDA was adjusted so that the content of OAPS in the polyimide / oligomeric silsesquioxane nano-hybrid film was 3.0 wt%. The added mass percentages of the reaction monomers in the film are BTDA 61.1wt% and ODA 35.9wt%.

Embodiment 3

[0043] According to the method of Example 1, the amount of ODA and additional BTDA was adjusted so that the content of OAPS in the polyimide / oligomeric silsesquioxane nano-hybrid film was 5.0 wt%. The added mass percentages of the reaction monomers in the film are 60.7wt% of BTDA and 34.3wt% of ODA.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com