High speed automatic bottle gas washer

An automatic, high-speed technology, applied in packaging, bottling machines, bottle filling, etc., can solve problems such as difficult application of packaging bottle conveyor belts, slow cleaning speed, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

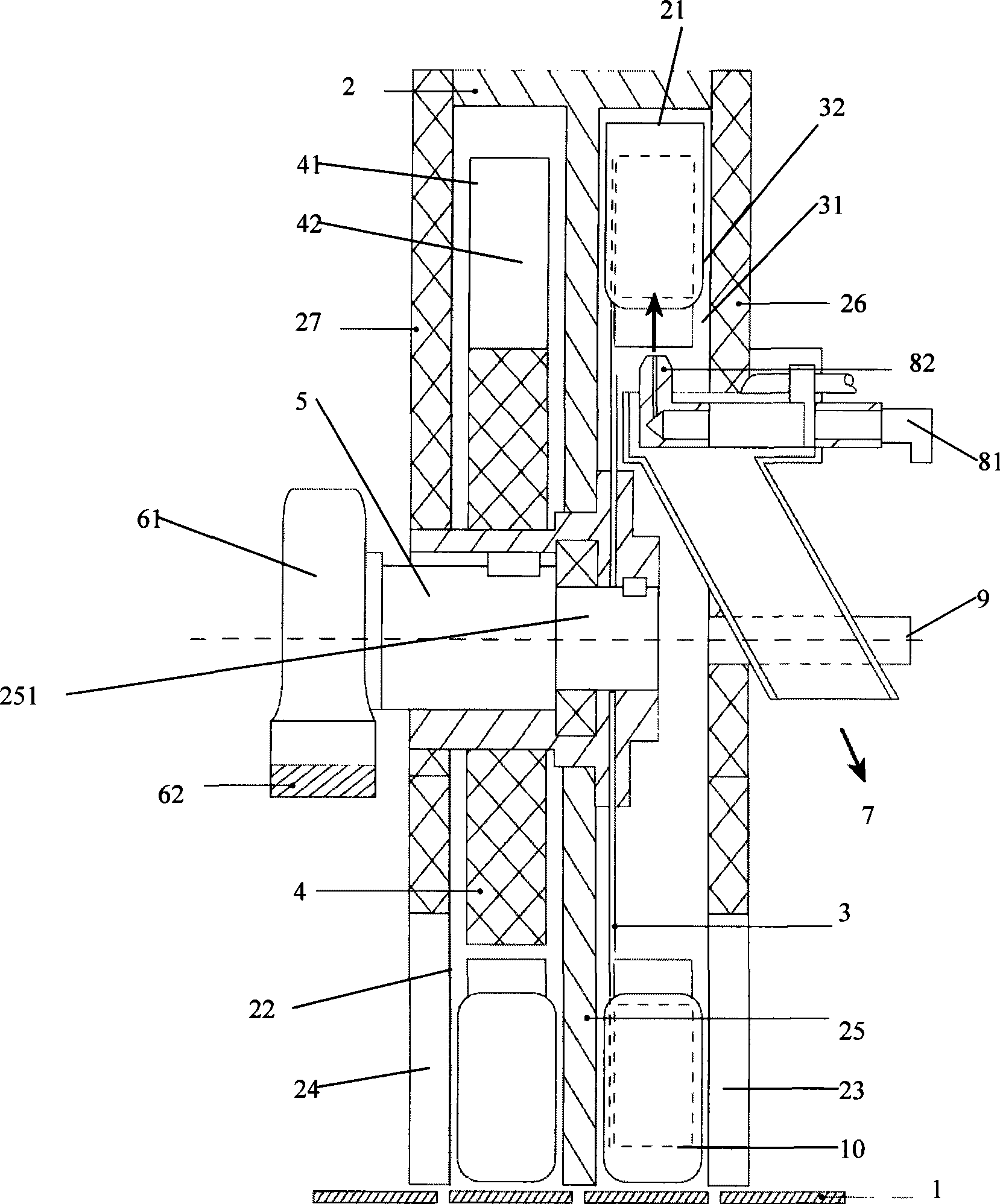

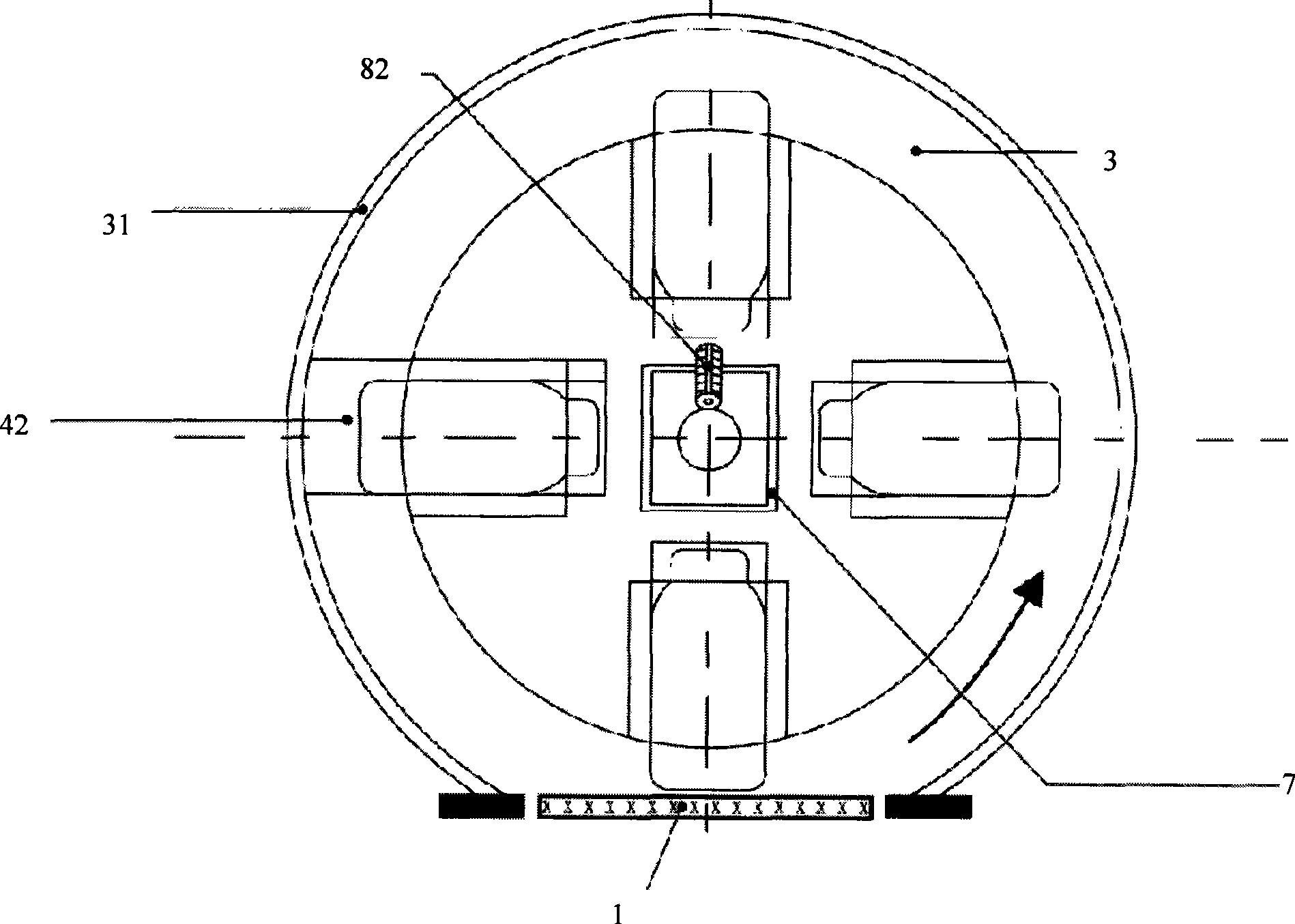

[0037] see figure 1 , 2 , which is a structural schematic diagram of the invention of a high-speed automatic air washing device. As shown it includes:

[0038] A housing 2 divided into left and right cavities 21, 22 by a partition 25; the housing 2 is located above the conveyor belt 1, and the front and rear cavities 21, 22 respectively have a bottle inlet 23 and a Bottle outlet 24, such as: this shell 21 has front and rear cover plates 26,27, and bottle inlet 23 and bottle outlet 24 are positioned at the bottom of front and rear cover plates 26,27 respectively.

[0039] The partition 25 has a bottle opening 251 communicating with the two cavities 21 , 22 .

[0040] A front cavity faceplate 3 and a rear cavity faceplate 4 are respectively arranged in the front and rear cavity bodies 21, 22, and their centers are penetrated by a controllable positioning rotating shaft 5 driven by a stepping motor 61 and can rotate coaxially , the stepping motor 61 is arranged on the frame 6...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com