Oxygen inhalation device clinical oxygen therapy

An oxygen and shell technology, applied in respirator and other directions, can solve problems such as loud noise, iatrogenic infection, and no other problems, and achieve the effect of obvious mildew and antibacterial, increase contact area, and obvious effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

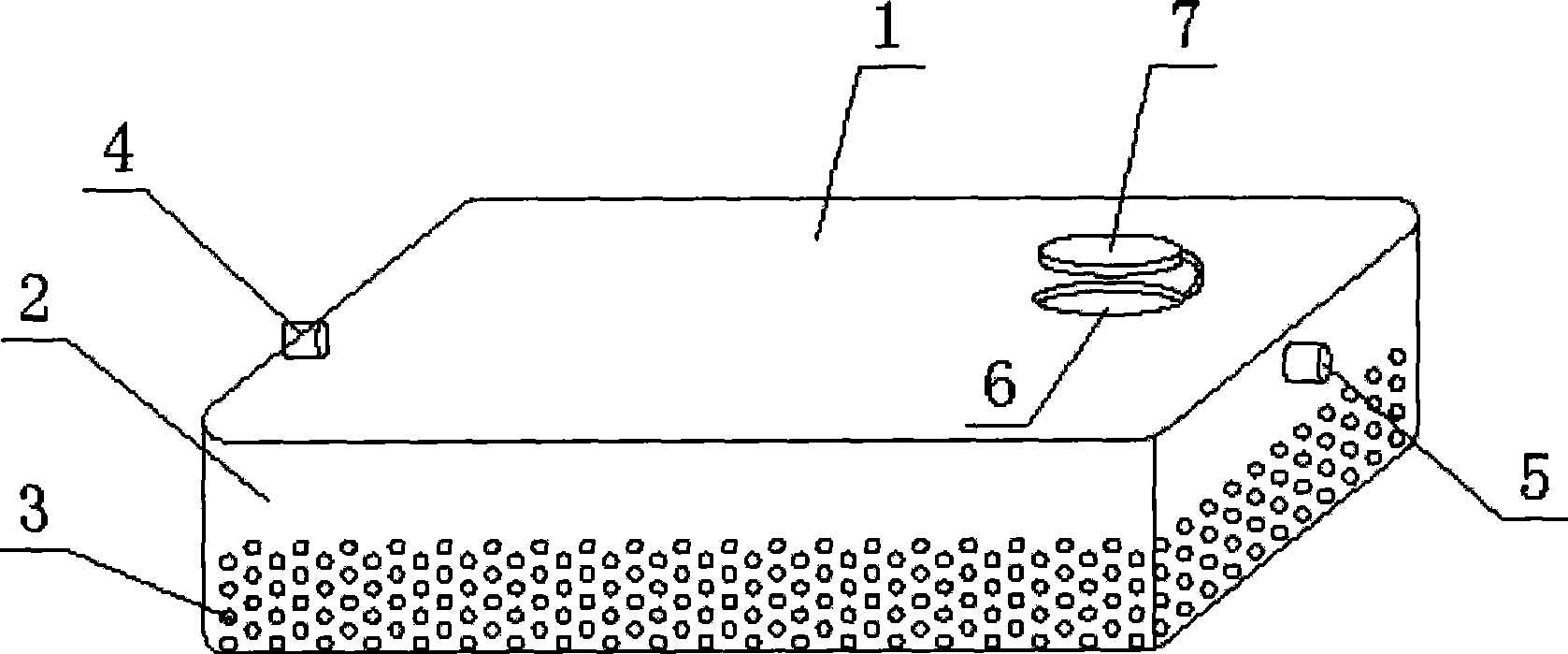

Image

Examples

Embodiment 2

[0020] The difference between this embodiment and Embodiment 1 is that: the casing of the humidification chamber is provided with a backflow partition in the oxygen passage.

[0021] The granular semi-fluid humidifier consists of the following components: 250ml of purified water, 0.5g of modified starch, 0.25g of lysozyme, and 0.5g of glycine.

Embodiment 3

[0023] The difference between this example and Example 1 is that the granular semi-fluid wetting agent consists of the following components: 250 ml of purified water, 0.5 g of modified starch, 0.01 g of paraben, and 0.2 g of sodium diacetate.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com