Two-stage turbo-charger engine system

A turbocharging and engine technology, applied in the direction of machines/engines, mechanical equipment, engine components, etc., can solve problems such as low performance and loss of heat energy, and achieve high performance, improved performance, and low pressure drop

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

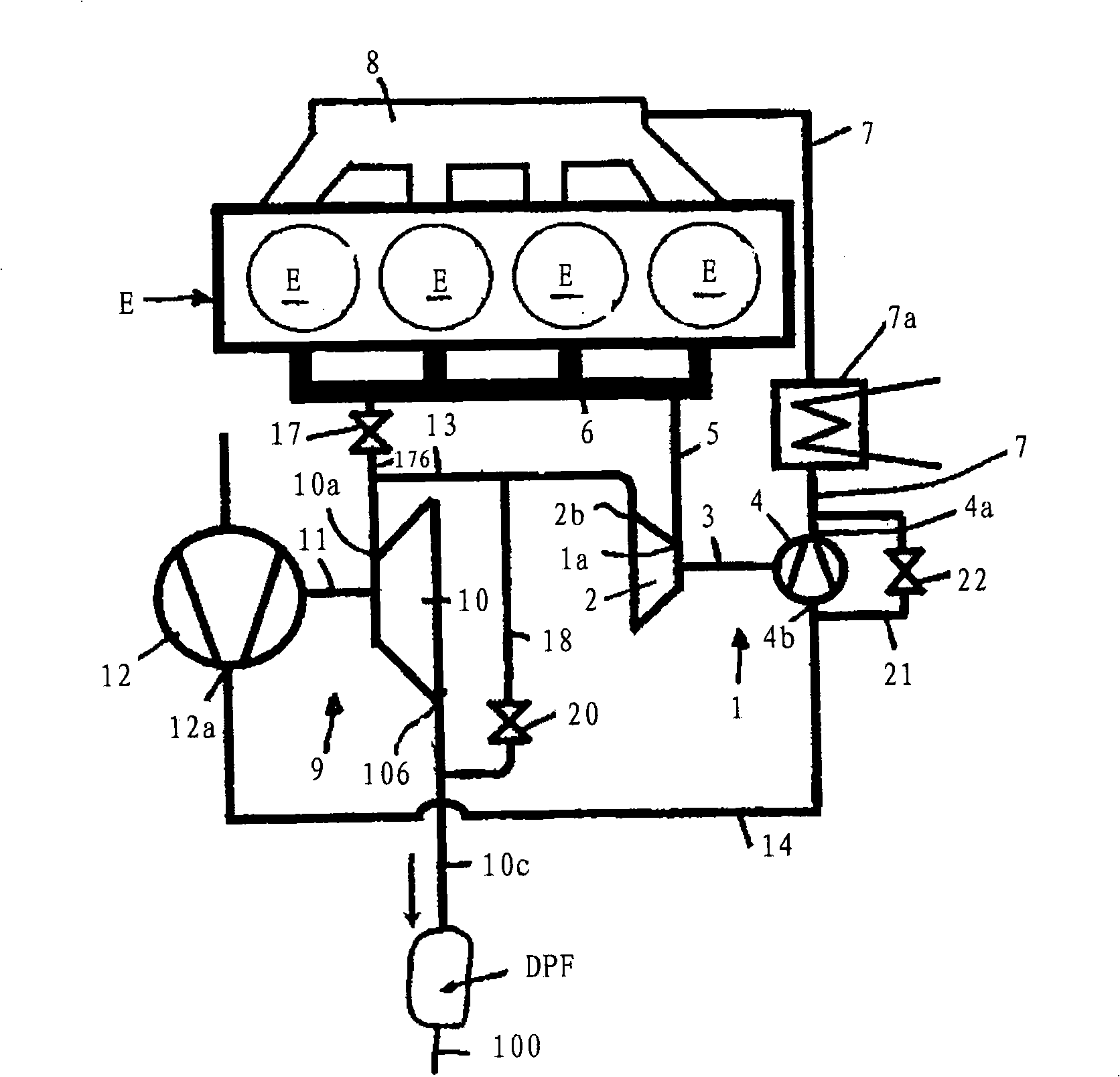

[0023] figure 1 The structure of an embodiment of the turbocharged engine system according to the invention is shown.

[0024] The turbocharged engine system has an engine E with 4 cylinders Z, a high-pressure turbocharger 1 , a low-pressure turbocharger 9 and a diesel particulate filter DPF. For clarity, other components of engine E are in figure 1 not drawn in.

[0025] The high-pressure turbocharger 1 comprises a high-pressure turbine 2 and a high-pressure compressor 4 driven by the high-pressure turbine 2 via a shaft 3 . The high-pressure turbine inlet 1 a is communicatively connected to an exhaust manifold 6 of the engine E through a high-pressure exhaust pipe 5 . The high-pressure exhaust pipe 5 is also called a high-pressure turbine connection pipe. The high-pressure compressor outlet 4a is communicatively connected to the intake manifold 8 of the engine E through the high-pressure intake pipe 7 . An intercooler 7 a is provided in the high-pressure intake pipe 7 . ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com