Three-dimensional quantum well CMOS integrated device and preparation method thereof

A technology of integrated devices and quantum wells, applied in semiconductor/solid-state device manufacturing, electric solid-state devices, semiconductor devices, etc., can solve the problem of low speed of three-dimensional integrated circuits, and achieve the goal of ensuring AC and DC electrical performance, improving performance, and improving performance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

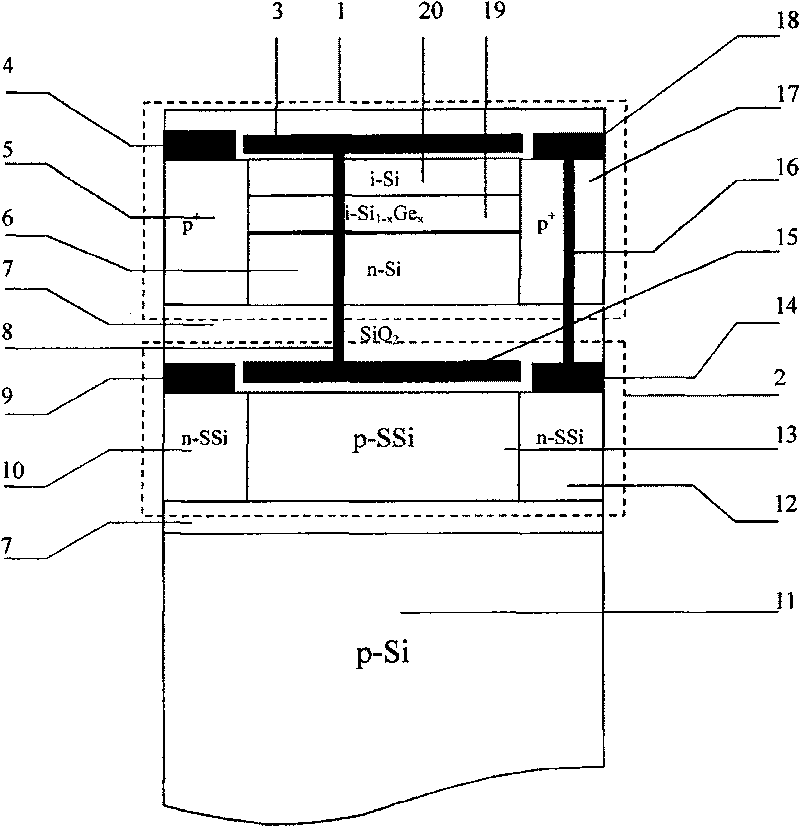

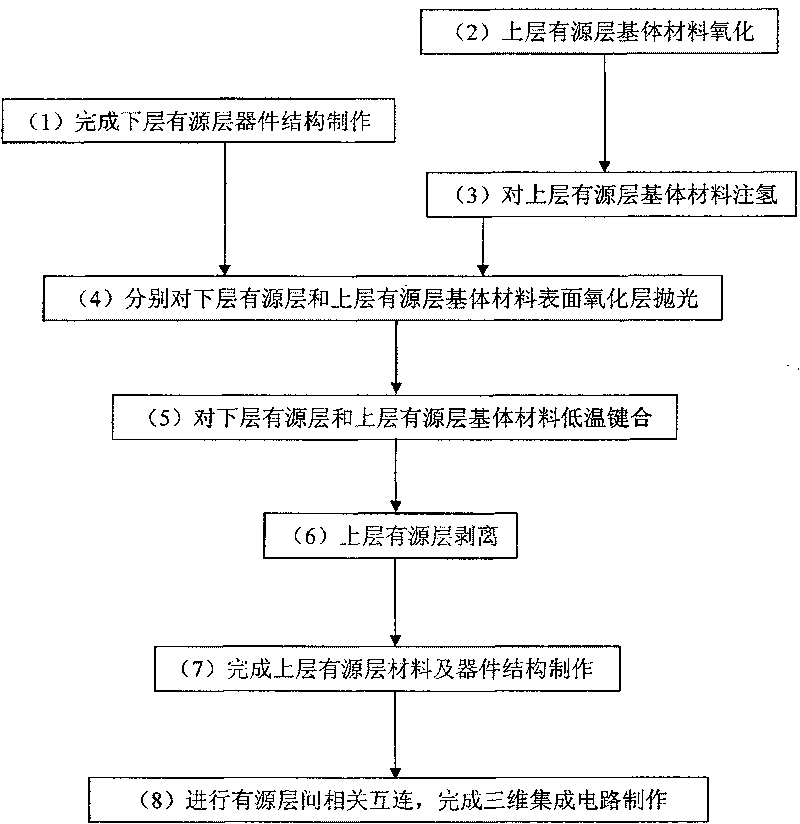

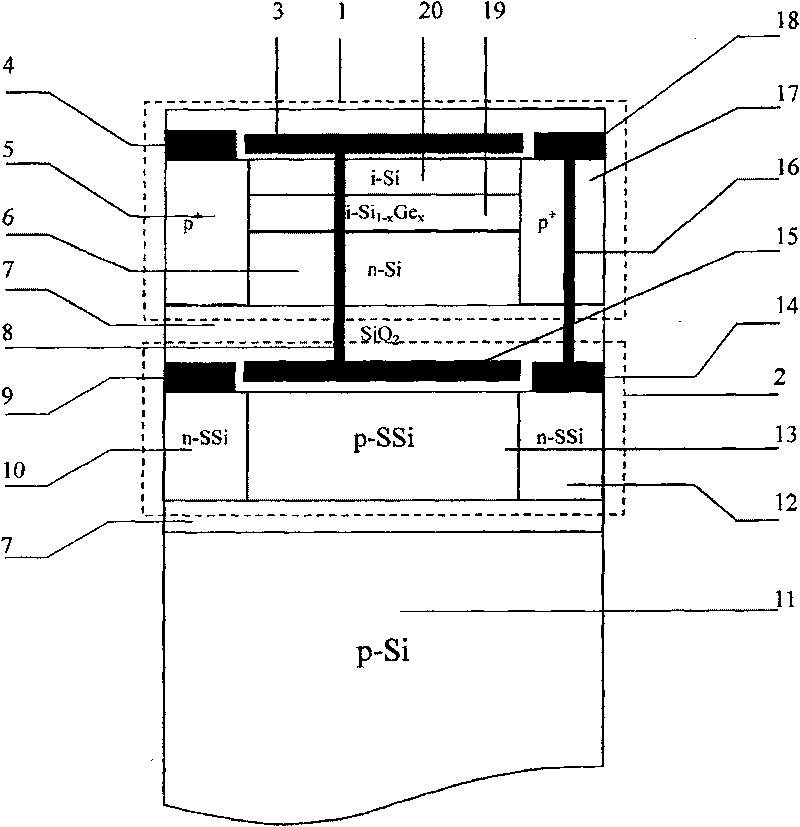

[0040] Embodiment 1: The steps for fabricating a three-dimensional quantum well CMOS integrated device with a 90nm conductive channel are as follows:

[0041] (1) Select SSOI substrate with stress> 1Gpa;

[0042] (2) On the SSOI substrate, use oxidation-photolithography source, drain, gate region-gate oxidation-deposition of polysilicon-photolithography of polysilicon and diffusion layer contact hole-deposition of polysilicon-photolithography of polysilicon-phosphorus implantation-low temperature deposition Product SiO 2 -Lithography lead hole-Polysilicon wiring-Low temperature deposition of SiO 2 Dielectric layer, fabricating strained Si nMOSFET device structure with 90nm conduction channel and interconnecting each other to complete the lower active layer structure;

[0043] (3) Depositing SiO on the surface of the above active layer 2 Dielectric layer

[0044] (4) Surface oxidation of the cleaned n-type Si wafer as the upper base material;

[0045] (5) Use ion implantation process to...

Embodiment 2

[0052] Embodiment 2: The steps for fabricating a three-dimensional quantum well CMOS integrated device with a 130 nm conductive channel are as follows:

[0053] (1) Select SSOI substrate with stress> 1Gpa;

[0054] (2) On the SSOI substrate, use oxidation-photolithography source, drain, gate region-gate oxidation-deposition of polysilicon-photolithography of polysilicon and diffusion layer contact hole-deposition of polysilicon-photolithography of polysilicon-phosphorus implantation-low temperature deposition Product SiO 2 -Lithography lead hole-Polysilicon wiring-Low temperature deposition of SiO 2 Dielectric layer, fabricating strained Si nMOSFET device structure with 130nm conduction channel and interconnecting to complete the lower active layer structure;

[0055] (3) Depositing SiO on the surface of the above active layer 2 Dielectric layer

[0056] (4) Surface oxidation of the cleaned n-type Si wafer as the upper base material;

[0057] (5) Use ion implantation process to implant...

Embodiment 3

[0064] Embodiment 3: The steps of fabricating a three-dimensional quantum well CMOS integrated device with a 65nm conductive channel are as follows:

[0065] (1) Select SSOI substrate with stress> 1Gpa;

[0066] (2) On the SSOI substrate, use oxidation-photolithography source, drain, gate region-gate oxidation-deposition of polysilicon-photolithography of polysilicon and diffusion layer contact hole-deposition of polysilicon-photolithography of polysilicon-phosphorus implantation-low temperature deposition Product SiO 2 -Lithography lead hole-Polysilicon wiring-Low temperature deposition of SiO 2 Dielectric layer, fabricating strained Si nMOSFET device structure with 65nm conduction channel and interconnecting to complete the lower active layer structure;

[0067] (3) Depositing SiO on the surface of the above active layer 2 Dielectric layer

[0068] (4) Surface oxidation of the cleaned n-type Si wafer as the upper base material;

[0069] (5) Use ion implantation process to implant hyd...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com