Oil electric compound energy-saving type closed-loop control system and control method thereof

A closed-loop control and energy-saving technology, applied in fluid pressure actuation system components, fluid pressure actuation devices, servo motors, etc., can solve problems such as excessive overflow of hydraulic equipment, low degree of automation, and inaccurate motor control. Achieve the effect of improved energy saving, convenient operation and lower oil temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

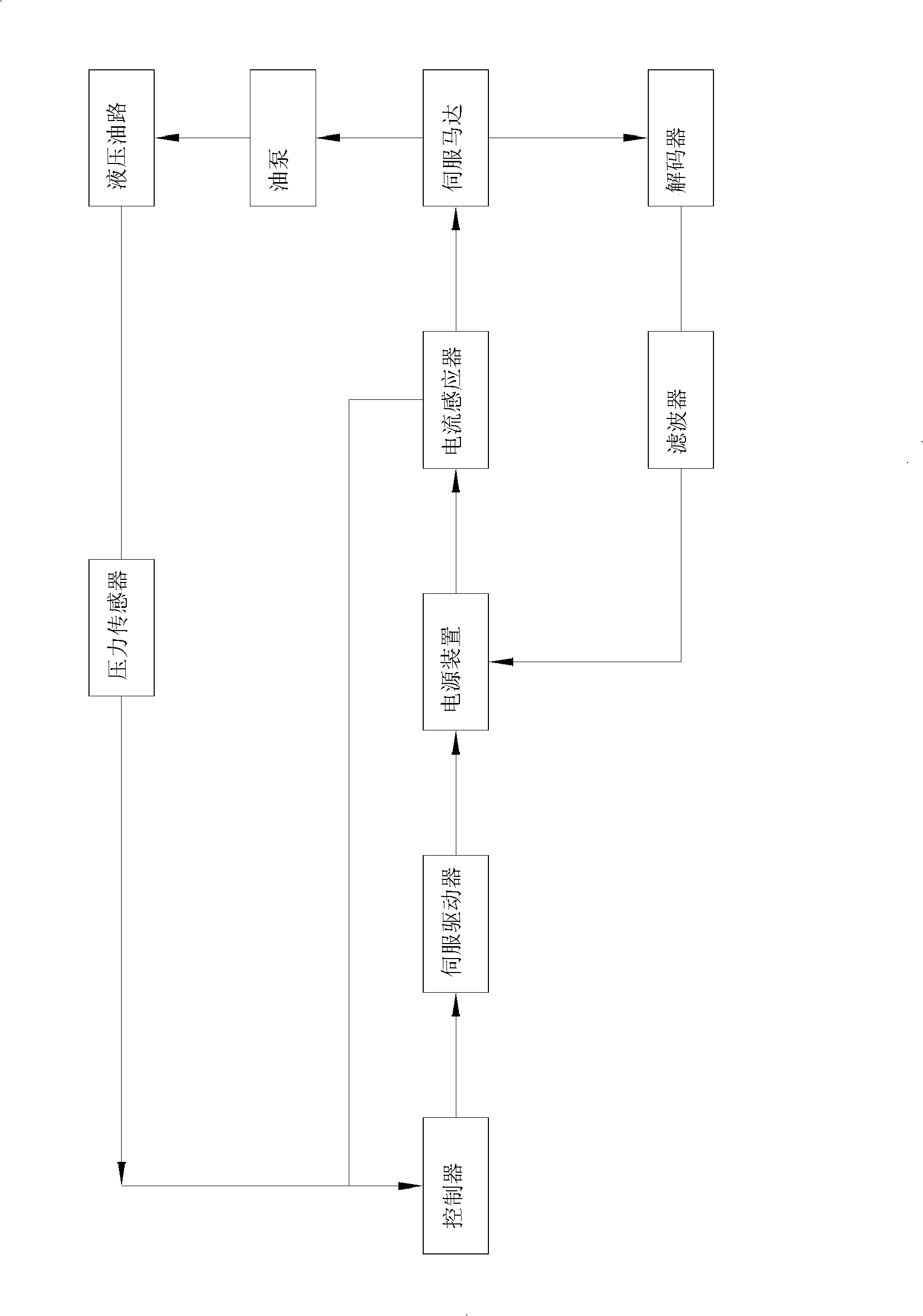

[0020] Example: attached figure 1 It is a structural schematic diagram of an oil-electric composite energy-saving closed-loop control system of the present invention. It is composed of a controller, a servo driver, a servo motor, a drive power supply device, a hydraulic oil circuit, a forward control circuit and a feedback circuit. The forward control circuit The controller, the servo driver, the drive power supply unit, and the servo motor are connected in sequence. The power output end of the servo motor is connected to the oil pump, and the working signal of the servo motor is fed back to the power supply unit through the feedback circuit. The feedback circuit is also connected with The decoder and filter convert the working signal of the motor from analog signal to digital signal, and then filter the digital signal, and feed back the required signal to the power supply device. A pressure sensor is arranged in the hydraulic oil circuit, and the signal circuit of the pressur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com