Double-mechanical sealing device in oil-gas mixed delivery pump

A technology of mechanical sealing device and oil-gas mixing pump, which is applied in mechanical equipment, components of pumping device for elastic fluid, pump, etc., can solve the problem of increased wear of dynamic and static ring friction pairs, shortened service life of double mechanical seal devices, etc. problems, to achieve the effect of prolonging the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] Specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

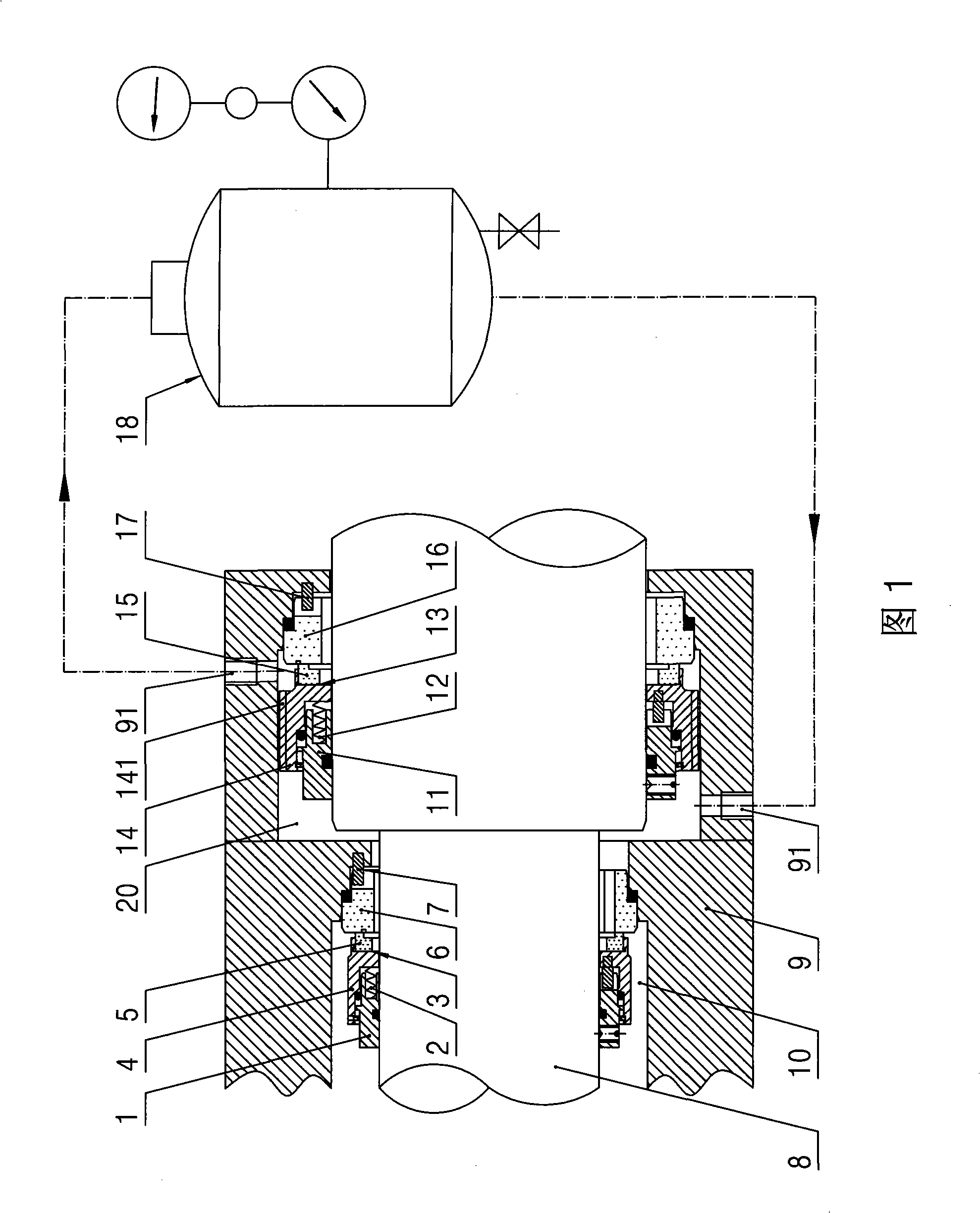

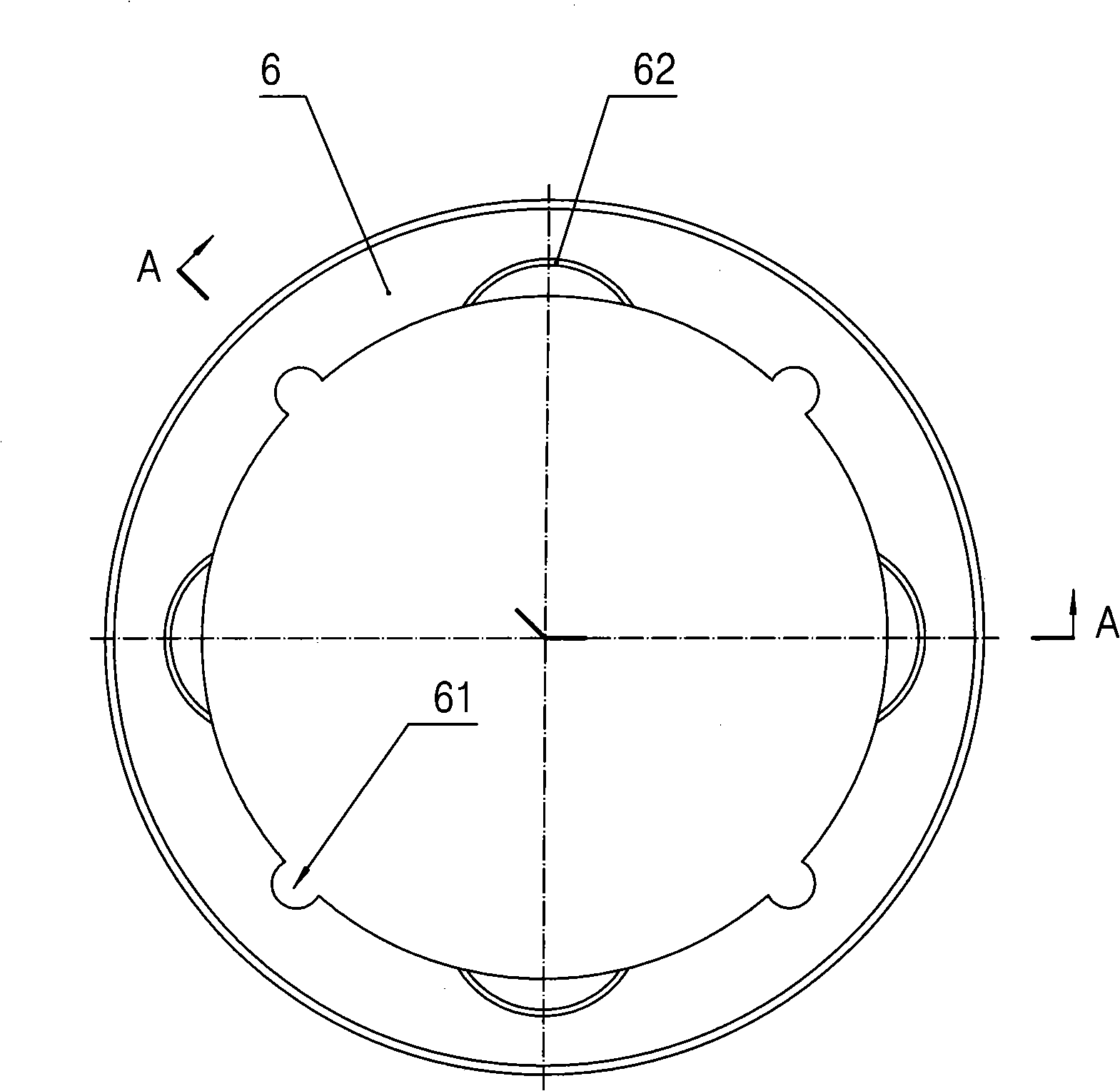

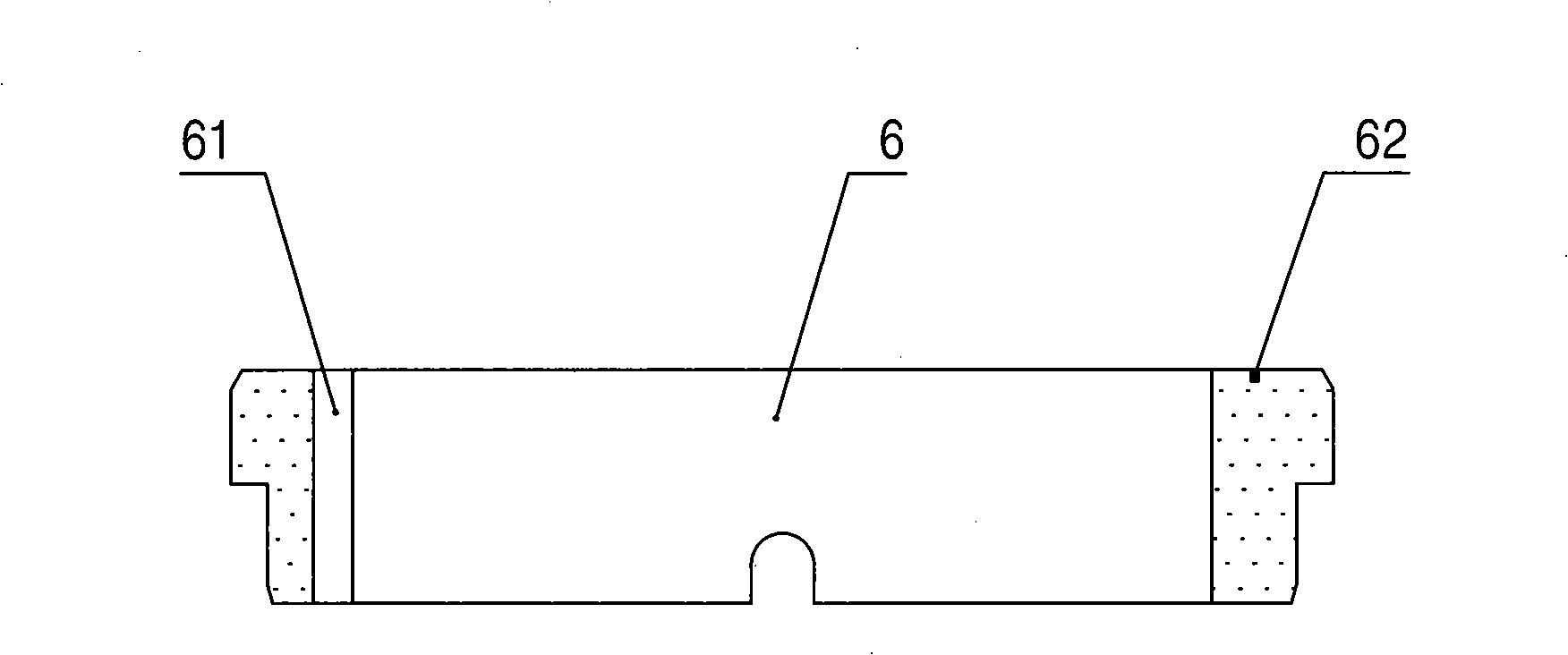

[0015] As shown in Figure 1, the double mechanical seal device in the oil-gas mixed transport pump according to the present invention includes: a pump body 9 and a pump shaft 8 which is movably arranged in the pump body 9, and the pump shaft 8 and the pump body 9 are arranged There are two sets of mechanical seals inside and outside, that is, the inner mechanical seal and the outer mechanical seal. The inner and outer mechanical seals separate the cavity between the pump body 9 and the pump shaft 8 into a sealing chamber 10 and a sealing liquid chamber 20; the inner mechanical seal includes: transmission Sleeve 1, moving ring 3 and static ring 6, the transmission sleeve 1 is fixed on the pump shaft 8, and sealed with the pump shaft 8 through the sleeve O-ring, the moving ring 3 is composed of the moving ring seat 4 and the moving ring piece 5, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com