Process steam flow control apparatus

A technology of steam flow and control device, which is applied to non-electric variable control, temperature control, control/regulation system, etc., can solve the problem that the temperature of process hot water cannot meet the production needs, the heat demand of process water fluctuates, and the steam control of small flow cannot be achieved. and other problems to avoid adverse effects, prolong service life, and improve reliability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

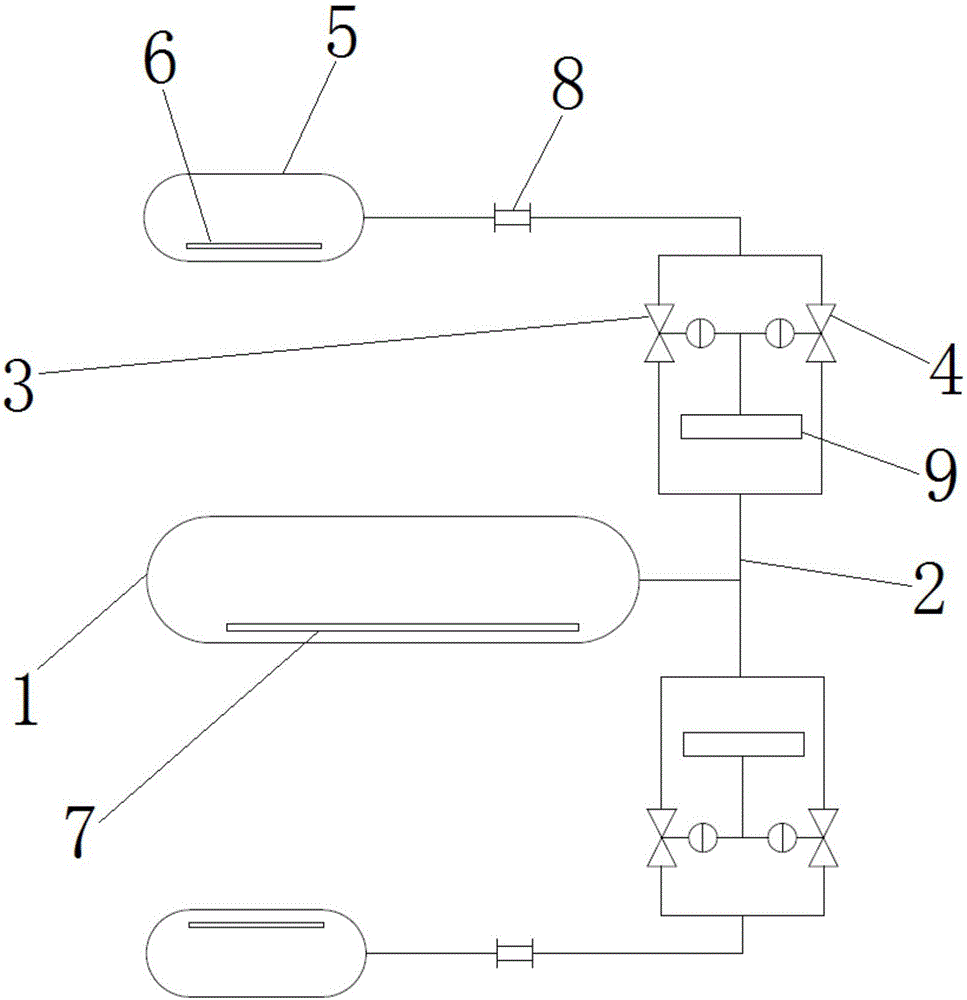

[0023] Such as figure 1 A process steam flow control device is shown, which includes a steam sub-cylinder 1 and two process steam supply units respectively connected with the steam sub-cylinder 1, and the process steam supply unit includes a steam sub-cylinder connected with the steam sub-cylinder 1 The steam supply pipeline 2, the first pneumatic valve 3 and the second pneumatic valve 4 arranged in parallel on the steam supply pipeline 2, and the time control switch control box electrically connected with the first pneumatic valve 3 and the second pneumatic valve 4 respectively , The end of the steam supply pipeline 2 is provided with a heat exchanger 5, which is a shell-and-tube heat exchanger. The device also includes an air compressor 9 communicating with the pneumatic actuators in the first pneumatic valve 3 and the second pneumatic valve 4 respectively. The process steam in the steam distribution cylinder 1 is sent to the heat exchanger 5 after the process steam supply ...

Embodiment 2

[0027] In this embodiment, there are three process steam supply units, and the rest are the same as in Embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com