Heat exchanger, thermal management system of vehicle and vehicle

A heat management system and heat exchanger technology, applied in the field of heat management systems and vehicles, can solve the problems of high manufacturing and development costs, low pressure resistance, low product generalization rate, etc., and achieve simple manufacturing process and convenient The effect of simple processing and structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

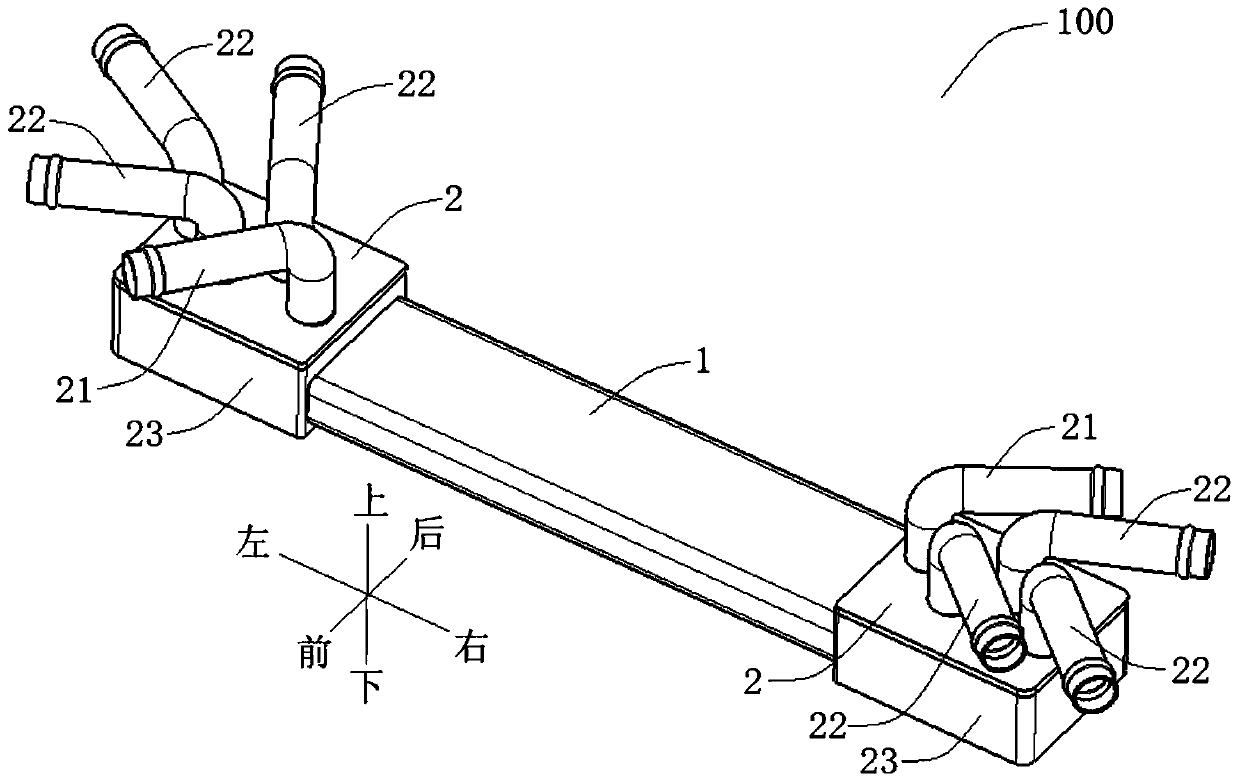

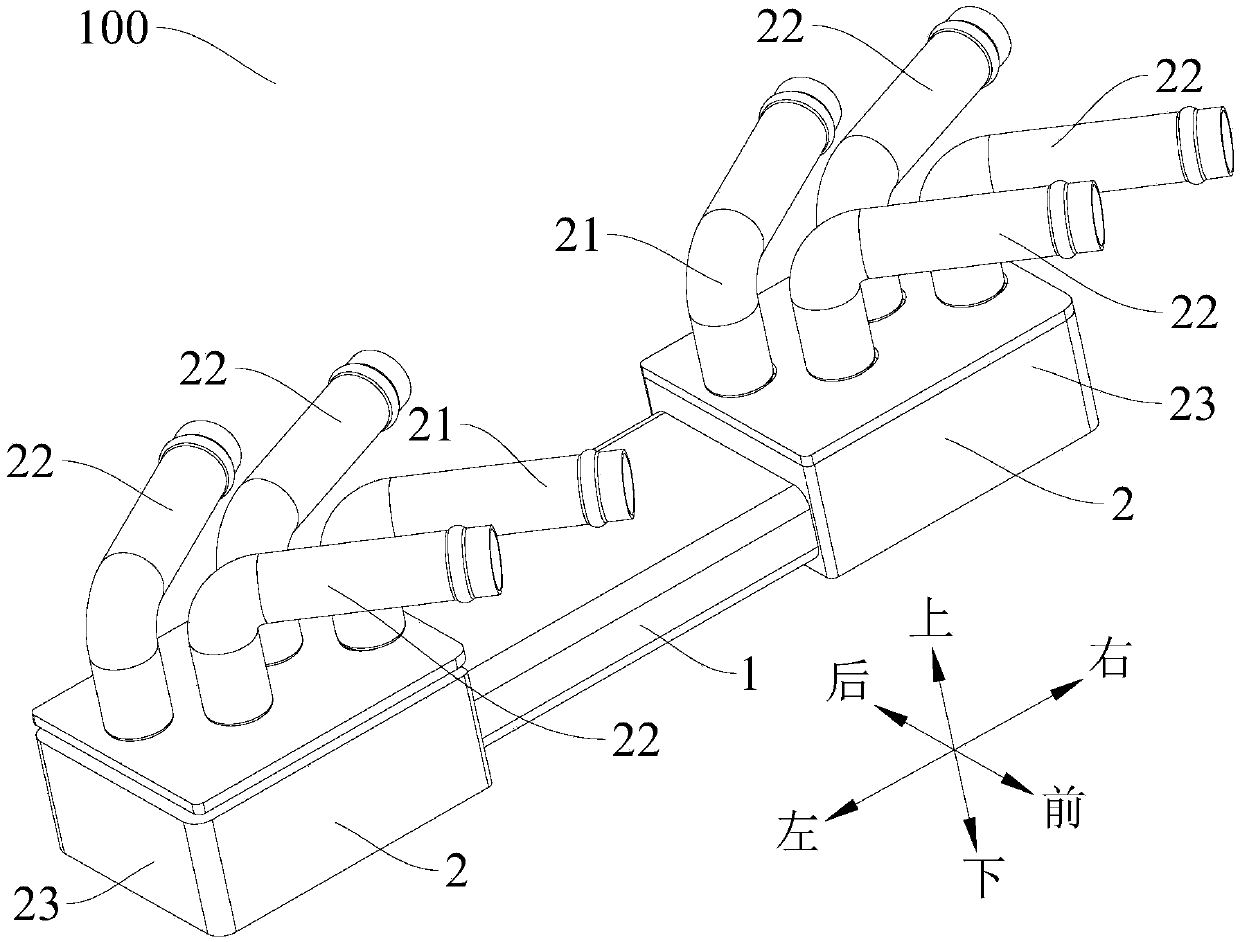

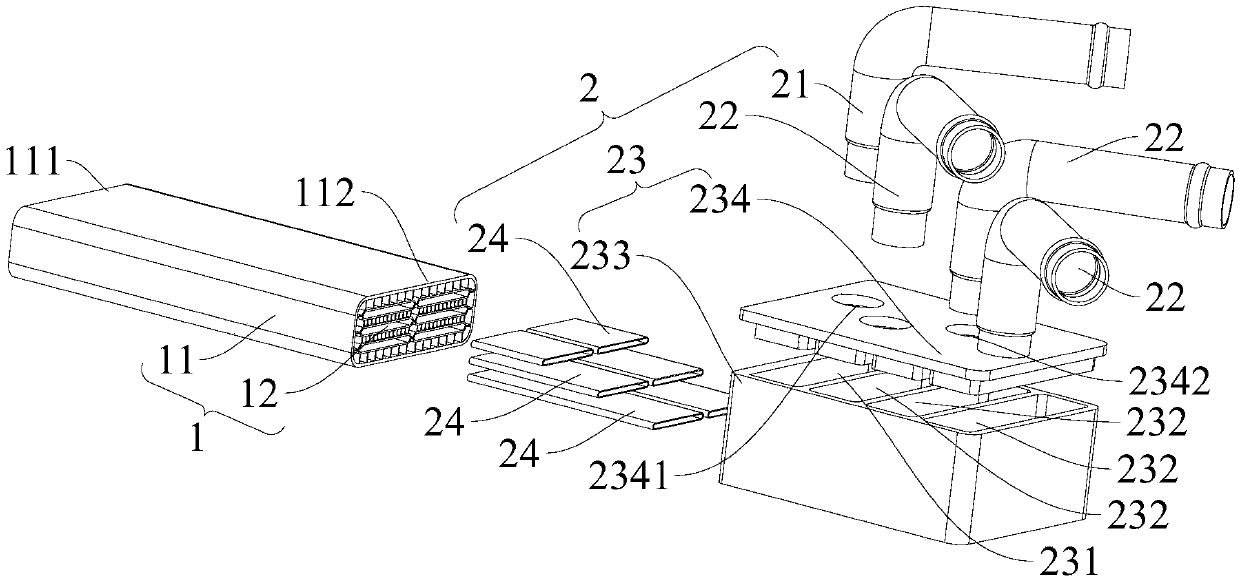

[0099] In this example, if Figure 2-Figure 8 As shown, the heat exchanger 100 includes a body 1 and two joints 2, the body 1 includes a shell 11 and a plurality of passages 12 formed in the shell 11, the shell 11 extends along a straight line, and the cross-sectional outer profile of the shell 11 is roughly formed as a square Structure, the cross-sectional shape of the shell 11 remains unchanged along its axial direction, and the shell 11 is an extruded integral piece; each channel 12 runs through the first end 111 of the shell along the length direction of the shell 11 to the second end of the shell Two ends 112, a plurality of passages 12 include a first passage 121 and three second passages 122, and the three second passages 122 are along the first direction (for example, Image 6 The upper and lower directions in the center) are spaced apart, so that each second passage 122 is surrounded by the first passage 121, so that heat exchange will not occur between different seco...

Embodiment 2

[0106] like figure 1 As shown, the structure of this embodiment is substantially the same as that of Embodiment 1, wherein the same components use the same reference numerals, the difference is that: the free ends of the first connecting pipes 21 of the two joints 2 respectively extend toward directions away from each other , the free ends of the corresponding second connecting pipes 21 of the two connectors 2 respectively extend in directions away from each other.

Embodiment 3

[0108] like Figure 9 As shown, the structure of this embodiment is substantially the same as that of Embodiment 1, wherein the same components use the same reference numerals, the difference is that: the two second sub-channels 1221 of one of the three second channels 12 At least one partition plate 1220 is provided to divide each second sub-channel 1221 into a plurality of sub-flow channels; at this time, the second channel 12 can flow into the refrigerant of the air-conditioning system of the vehicle 300 .

[0109] Refer below Figure 10 and Figure 11 The thermal management system 200 of the vehicle 300 according to the embodiment of the present invention is described in detail with two specific embodiments. It should be understood that the following description is only an illustration rather than a specific limitation to the invention.

[0110] Embodiment one

[0111] In this example, if Figure 10 As shown, the thermal management system 200 includes a heat exchanger...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com