Drum type washing machine

A drum-type washing machine, a washing machine technology, applied to other washing machines, control devices of washing machines, washing devices, etc., can solve the problems such as the inability to operate the electric motor and the temperature rise of the first electric motor.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

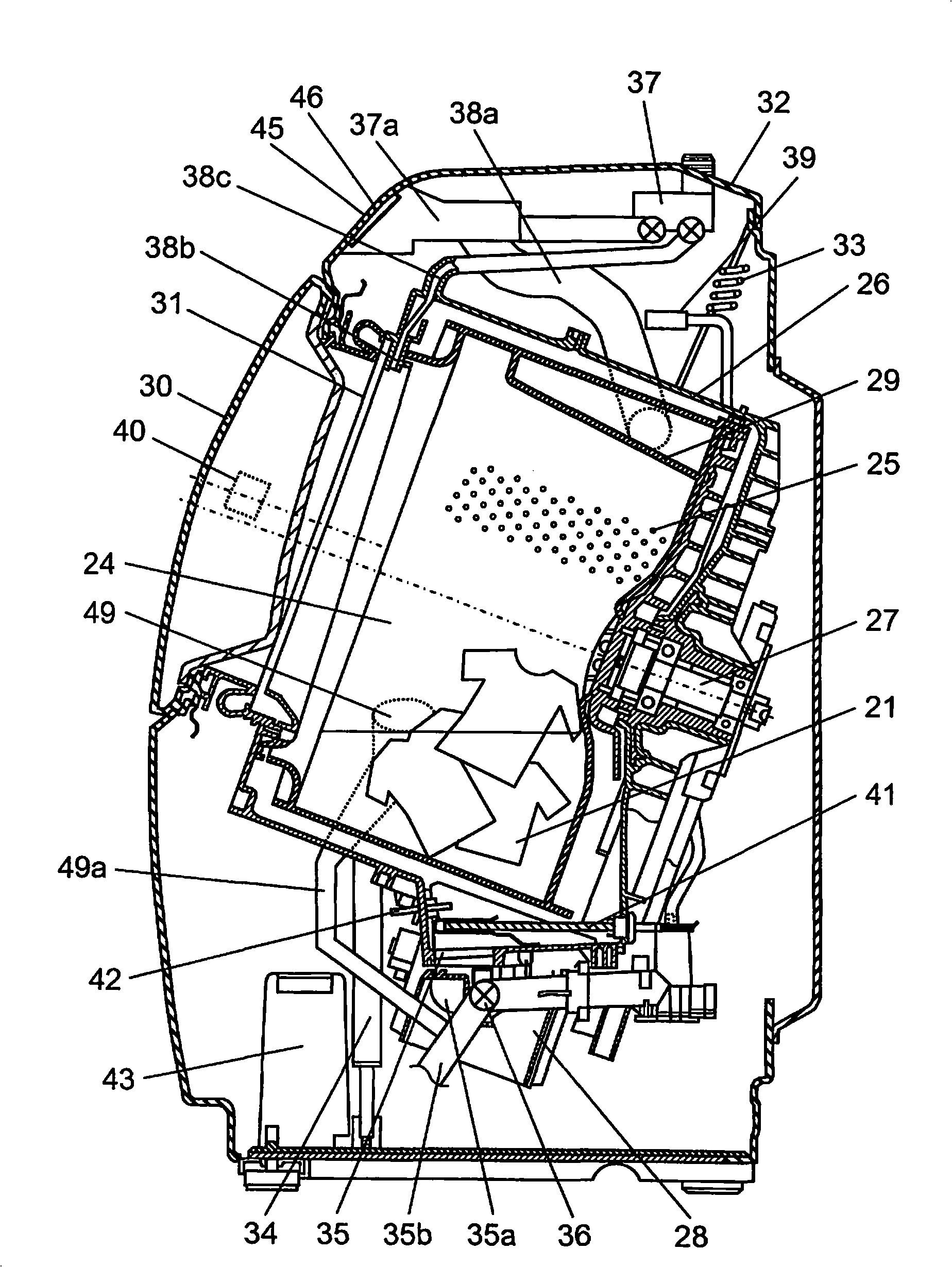

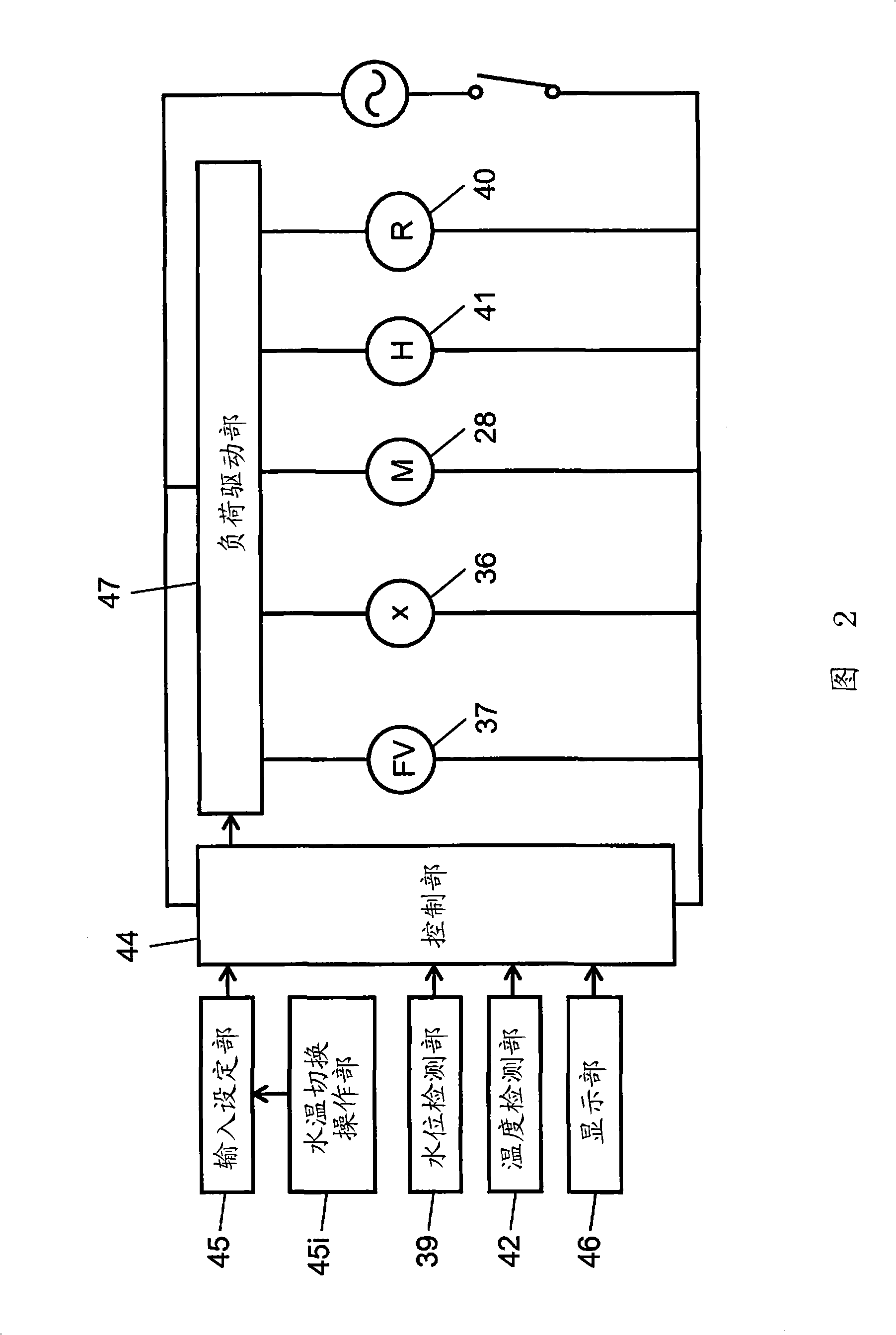

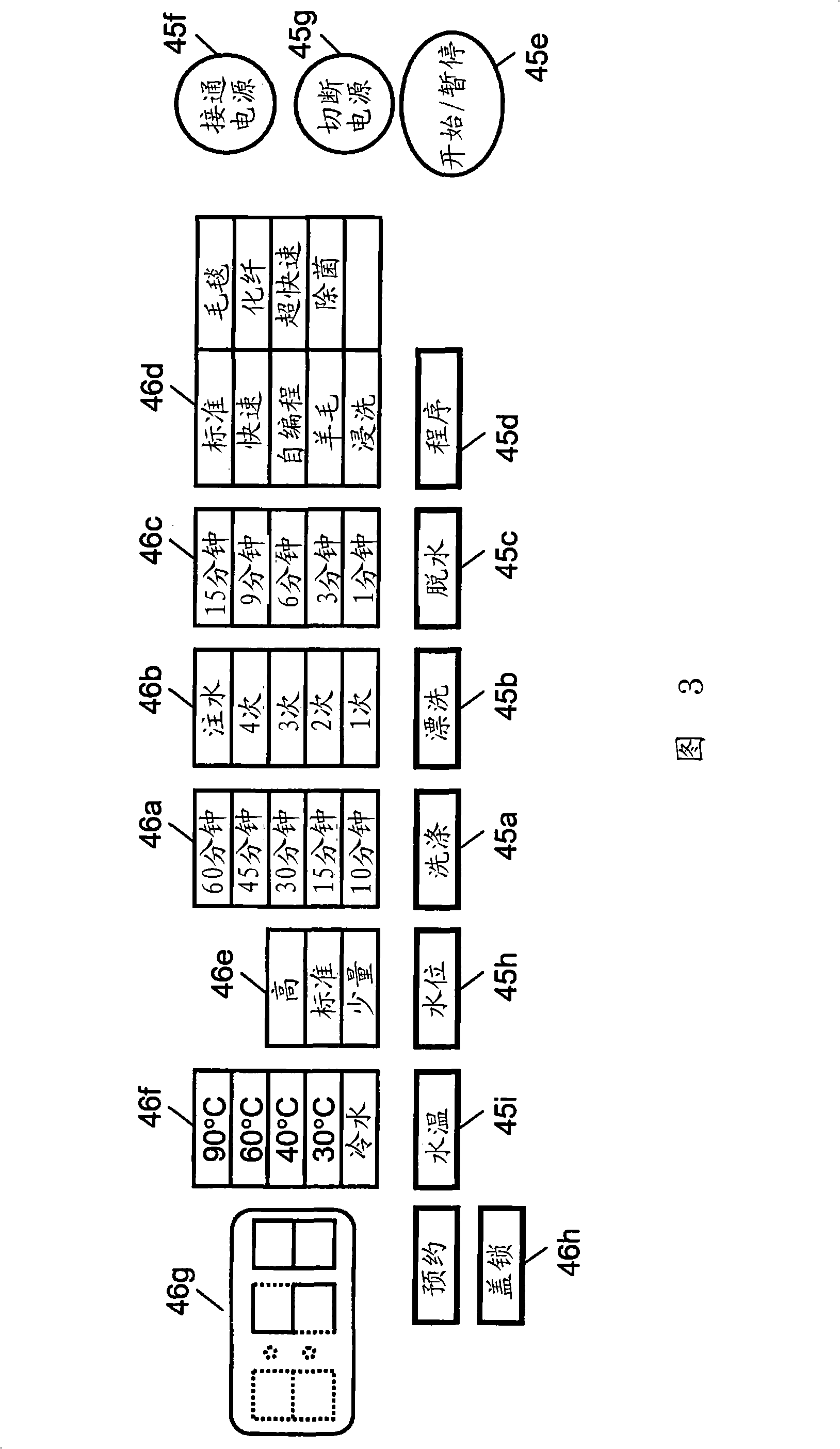

[0037] figure 1 It is a longitudinal sectional view of the front-loading-type washing machine in Embodiment 1 of the present invention. Such as figure 1 As shown, the rotary drum 24 is formed in a bottomed cylindrical shape, and a plurality of water passage holes 25 are provided on the entire outer peripheral surface thereof, and the rotary drum 24 is rotatably arranged in a water tank 26 . A rotating shaft (rotation center axis) 27 is provided substantially obliquely at the center of rotation of the rotating drum 24, and the rotating drum 24 is arranged so that the axial direction of the rotating drum 24 is inclined downward from the front side toward the rear side. A motor 28 attached to the back surface of the water tank 26 is connected to the rotating shaft 27, and the motor 28 drives the rotary drum 24 to rotate in the forward rotation direction and the reverse rotation direction. Several protruding plates 29 are arranged on the inner wall of the rotary drum 24, which...

Embodiment approach 2

[0077] Figure 8A , Figure 8B It is a flow chart of the operation of main parts of the front-loading-type washing machine according to Embodiment 2 of the present invention. Since the longitudinal sectional view, module control circuit diagram, input setting unit, and display unit of the drum-type washing machine according to Embodiment 2 of the present invention are the same as those of the drum-type washing machine according to Embodiment 1 of the present invention, the same reference numerals are assigned to the same structural elements, Its description is omitted.

[0078] Such as Figure 8A , Figure 8B As shown, in the second agitation process of the front-loading-type washing machine according to Embodiment 2 of the present invention, when the rotation of rotary drum 24 is temporarily stopped, the process shifts to the first agitation process. More specifically, in the second stirring process, stirring 2 is performed in step 112 . Then, when the stirring time S ha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com