Ultra-high molecular weight polyethylene thread separation carding machine

A polyethylene fiber, ultra-high molecular weight technology, applied in the direction of single-component polyolefin rayon, fiber processing, textiles and papermaking, etc., can solve the problem of large investment, can not be completely improved, affects the production efficiency and the internal quality of finished fibers, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

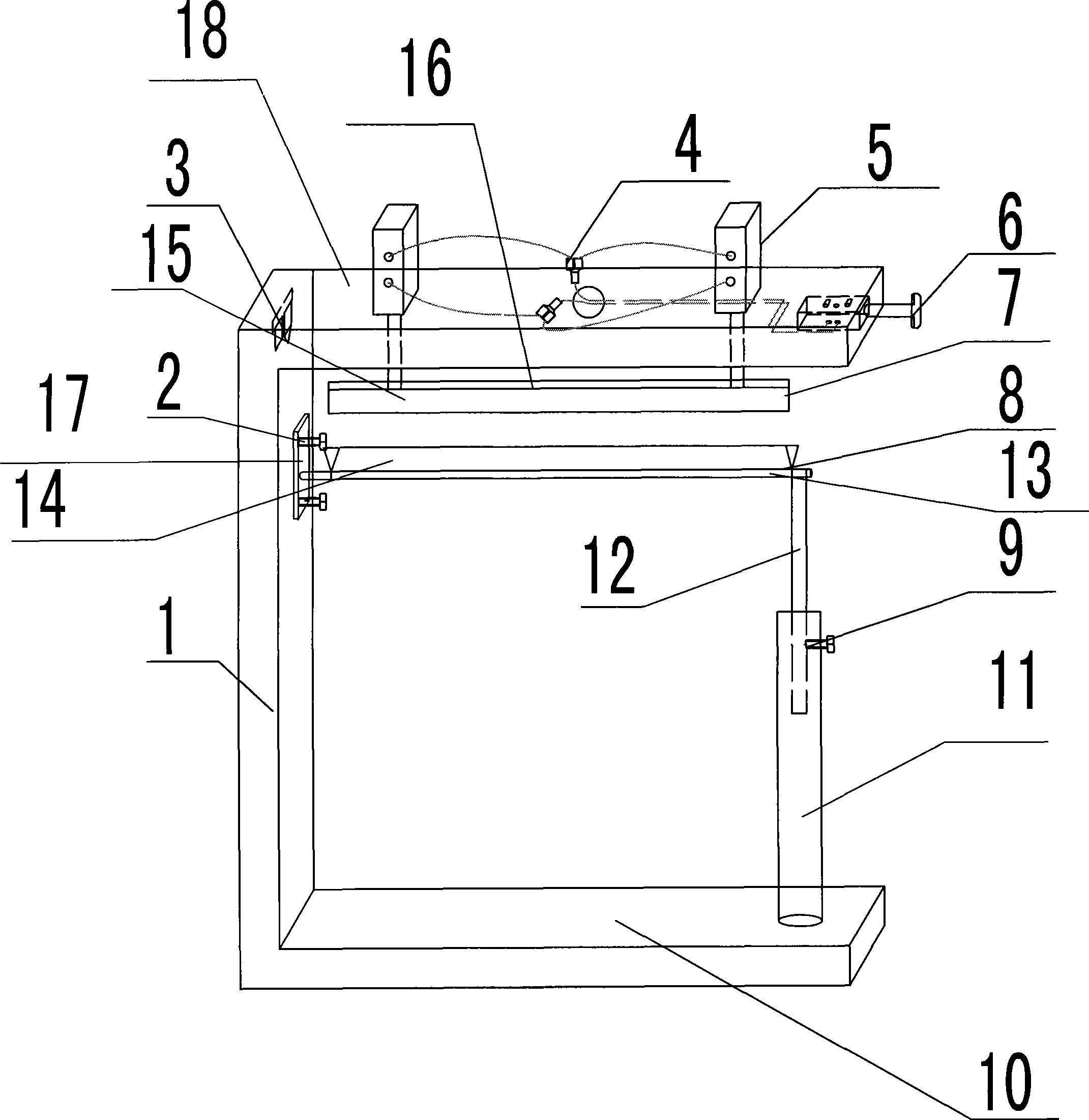

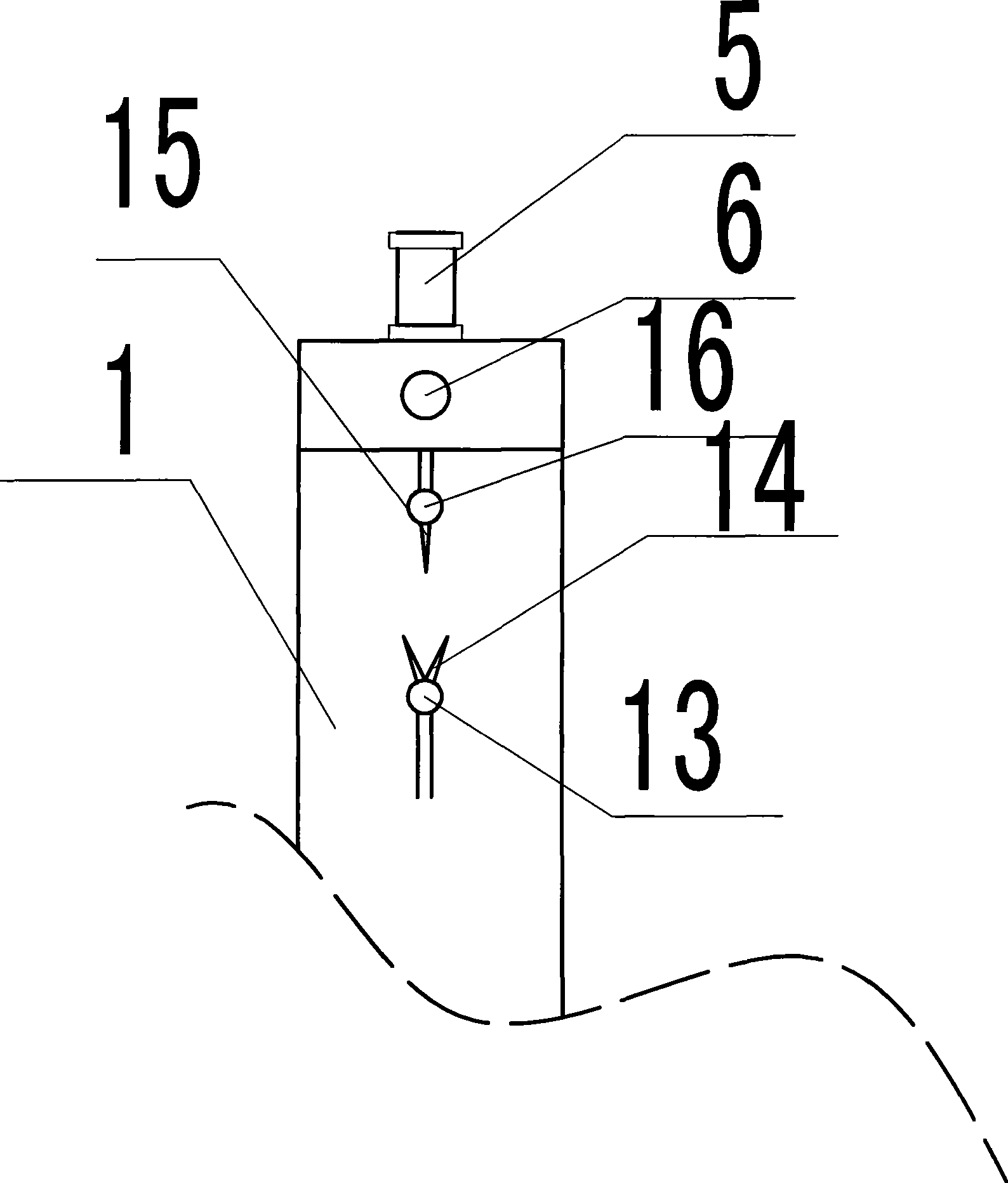

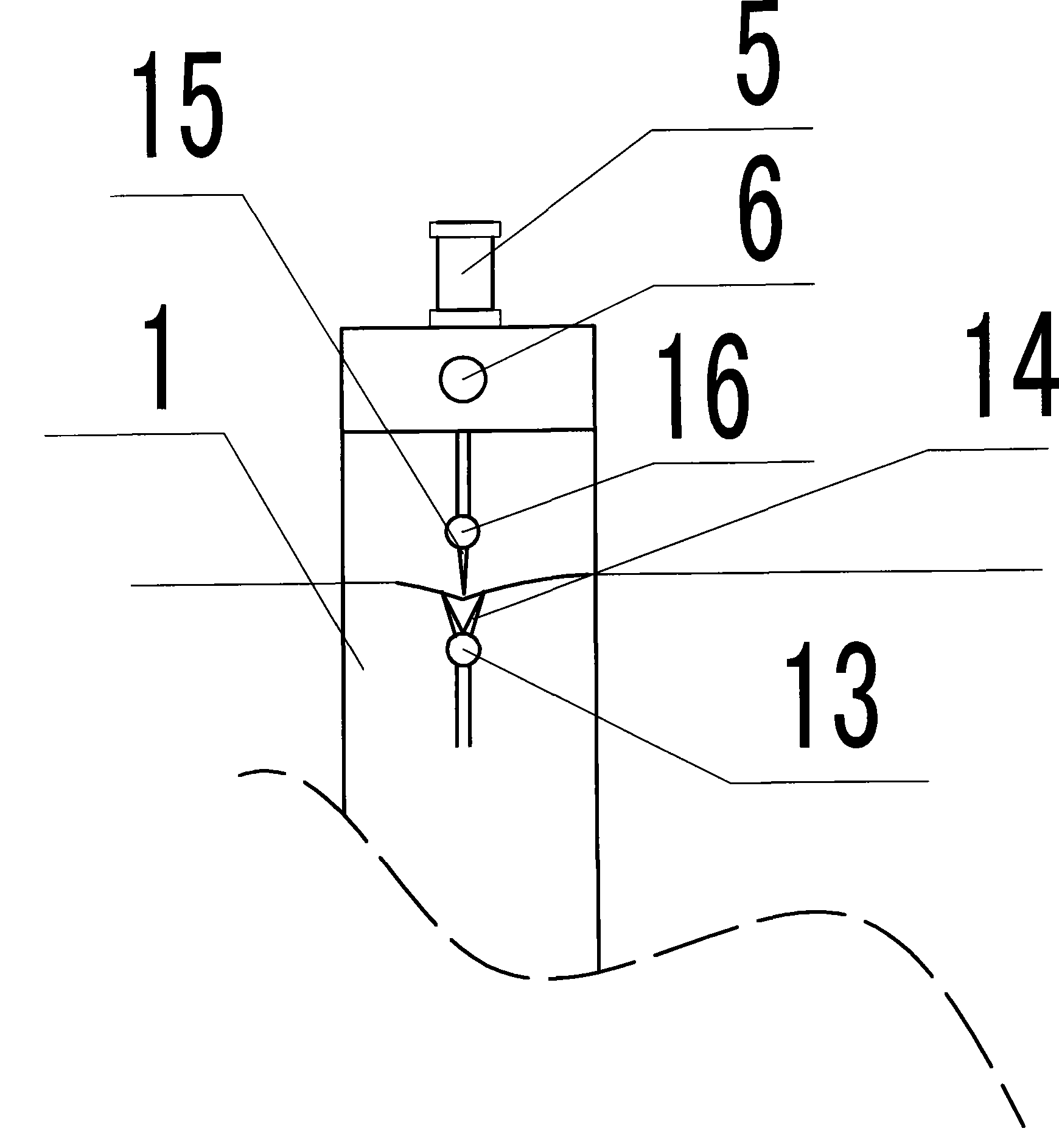

[0016] Example: such as figure 1 As shown, an ultra-high molecular weight polyethylene fiber splitting card is composed of a placement mechanism, a left frame balance adjustment mechanism, a right frame balance adjustment mechanism, a carding mechanism, and a pneumatic control mechanism; the placement mechanism consists of a base 10 and a Rack 1 constitutes, base 10 and rack 1 into " ” shape; the left frame balance adjustment mechanism is made up of support pad 17 and left frame balance adjustment screw 2, by adjusting the left frame balance adjustment screw 2, the lower carder 8 is kept level; the right frame balance adjustment mechanism is composed of Support rod 12, pillar 11 and right frame balance adjustment screw 9 are formed, and support rod 12 is inserted in the pillar 11, and right frame balance adjustment screw 9 is inserted on the pillar 11, and the bottom end of pillar 11 is fixed on the base 10, One end of the support rod 12 is fixed with the lower balance bar 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com