Field magnet frame for removing iron dust in plastic

A technology of using magnets and iron filings, applied in the field of magnet racks for removing iron filings from plastics, can solve the problems of insufficient adsorption of iron filings powder, loss of magnetism of magnet bars, and difficulty in breaking apart and cleaning, so as to reduce the influence of the flow direction of objects and prolong The effect of long service life and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with accompanying drawing and specific embodiment:

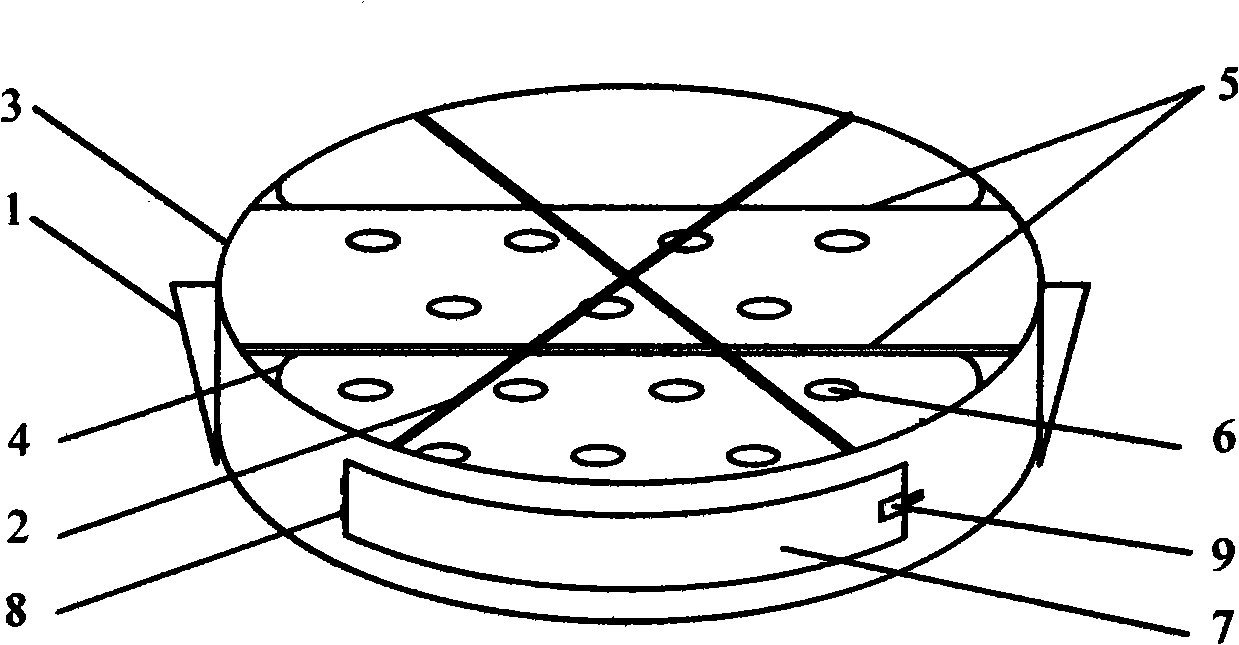

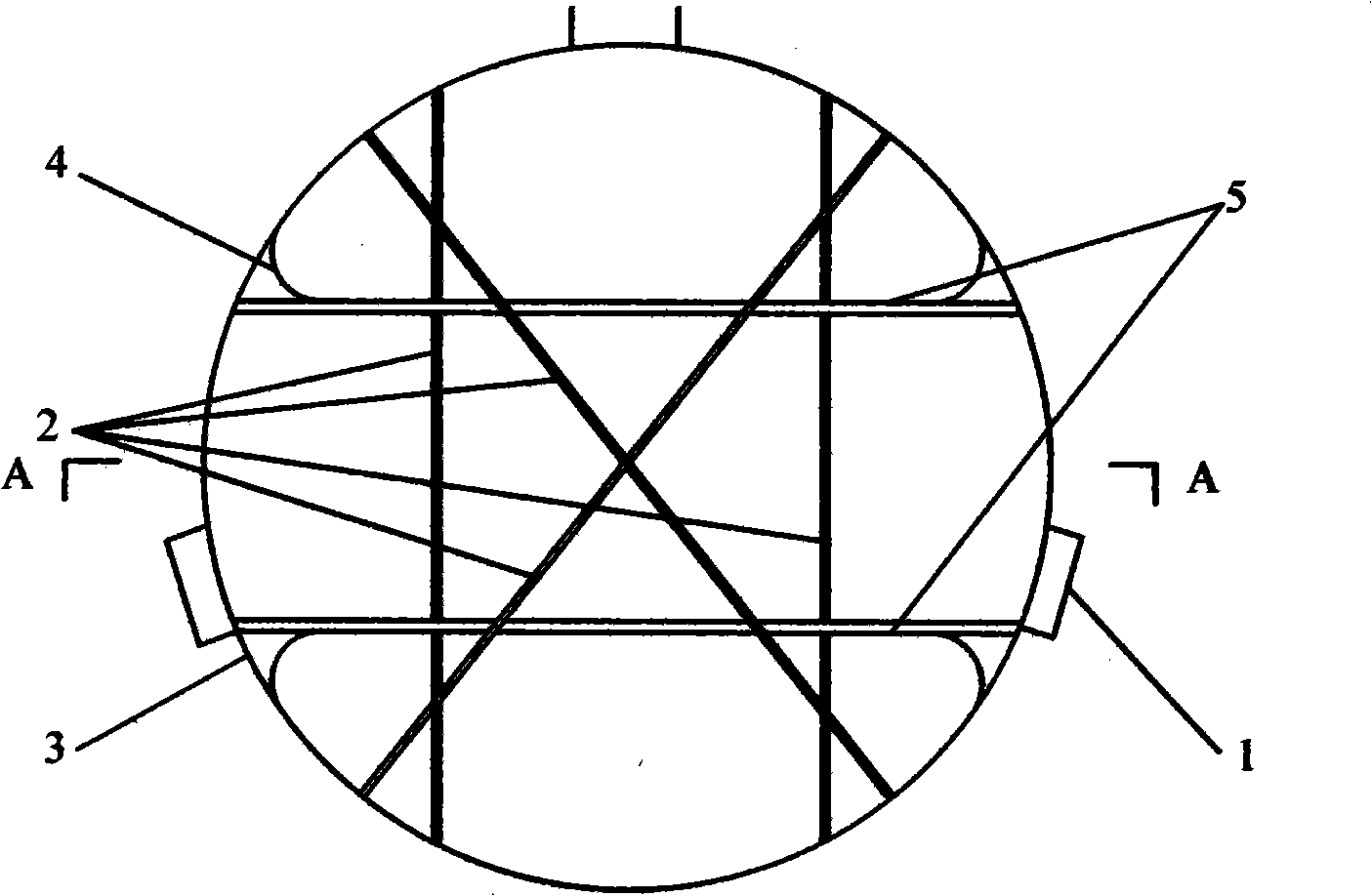

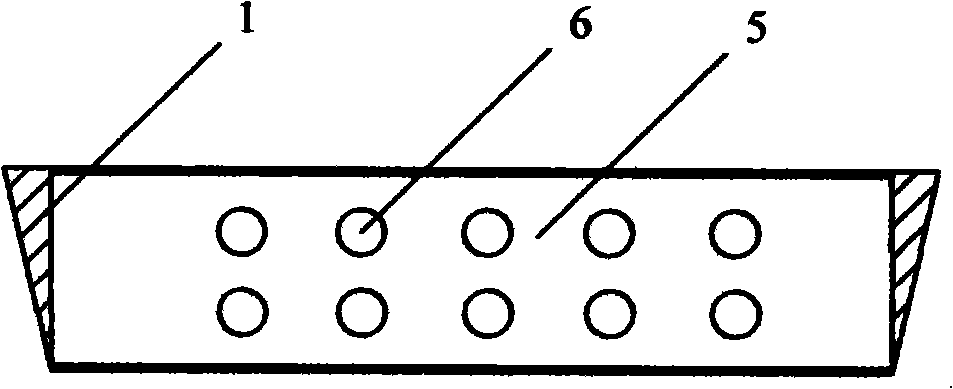

[0020] Such as figure 1 , 2 As shown in and 3, a magnet frame for plastic iron filings includes a frame body and support feet 1, the frame body is a protective ring 3 with upper and lower openings, and at least two parallel placement plates 5 are vertically fixed in the protective ring. A plurality of placement holes 6 for placing magnet rods are opened on the placement plate 5 according to requirements. The placement holes 6 are divided into upper and lower rows, and the placement holes 6 of the upper row and the lower row are evenly distributed in a staggered manner, and their apertures are slightly larger than the diameter of the magnet rods. , in order to disassemble the magnet bar. Of course, the number of magnet bars can also be adjusted according to product needs and requirements. One side of the protective ring 3 is provided with a dodge d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com