Method for preparing monodisperse flower-shaped gold/platinum hybrid nano particles having different particle diameters

A technology of hybrid nanoparticles and gold nanoparticles, applied in chemical instruments and methods, metal/metal oxide/metal hydroxide catalysts, physical/chemical process catalysts, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0012] a. Preparation of 25 nm gold nanoparticles

[0013] Put 0.5-2 ml of 24.3mM / LHAuCl 4 The aqueous solution was added to 50-200 ml of distilled water and heated to boiling, and then 0.75-3 ml of 34.3 mM / L sodium citrate aqueous solution was quickly added to obtain 25 nm gold nanoparticles after heating for 10 minutes;

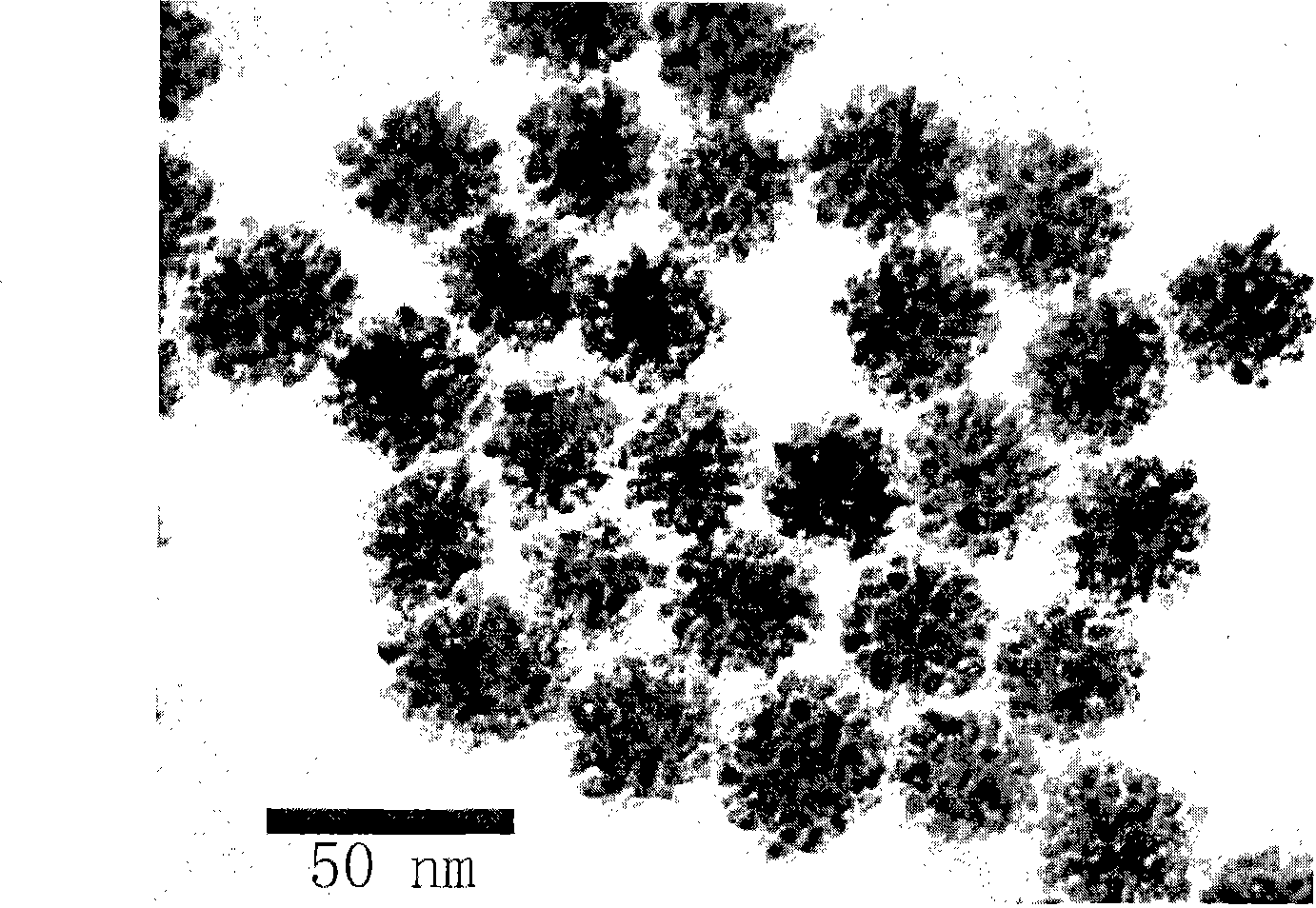

[0014] b, with the gold nanoparticles obtained above as seeds, with 0.1M / L ascorbic acid as green reducing agent, with 19.3mM / L H 2 PtCl 6 As a platinum source, the molar ratio of platinum to gold is 2:1, 0.1M / L ascorbic acid and 19.3mM / L H 2 PtCl 6 The volume ratio is 0.8-2, and heated at 100° C. for 15 minutes to obtain monodisperse flower-shaped gold / platinum hybrid nanoparticles with a particle size of 35 nm.

Embodiment 2

[0016] a. Preparation of 13nm gold nanoparticles

[0017] In 2.12 mL of 24.3mM / LHAuCl 4 The aqueous solution was added to 50 ml of distilled water and heated to boiling, then 5.7 ml of 34.3 mM / L sodium citrate aqueous solution was added rapidly. After heating for 10 minutes, gold nanoparticles of 13 nm were obtained;

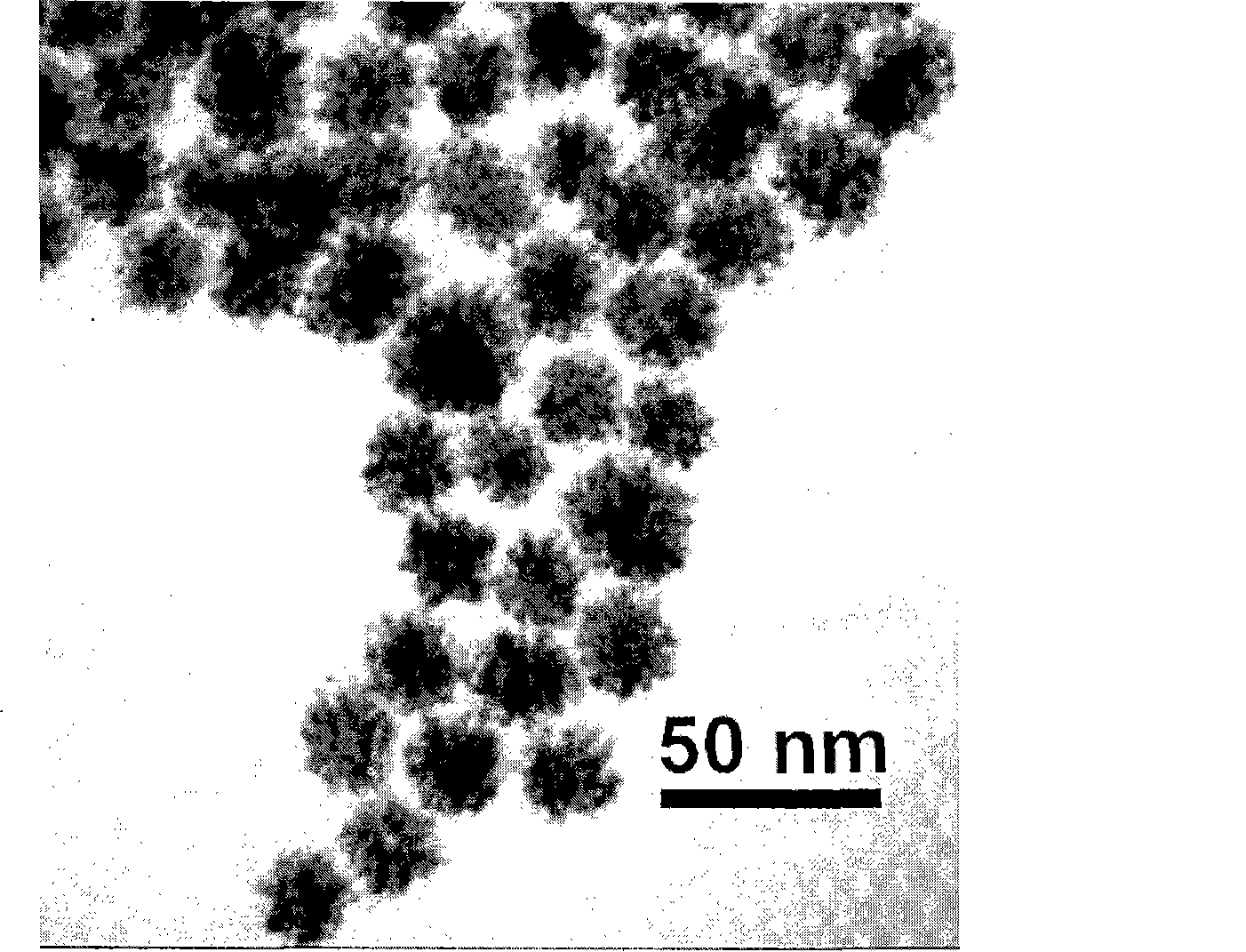

[0018] b, with the gold nanoparticles obtained above as seeds, with 0.1M / L ascorbic acid as green reducing agent, with 19.3mM / L H 2 PtCl 6 As a platinum source, the molar ratio of platinum to gold is 2:1, 0.1M / L ascorbic acid and 19.3mM / L H 2 PtCl 6 The volume ratio is 0.8-2, and heated at 100° C. for 15 minutes to obtain monodisperse flower-shaped gold / platinum hybrid nanoparticles with a particle size of about 20 nanometers.

Embodiment 3

[0020] a. Preparation of 3 nm gold nanoparticles

[0021] In 0.5-2ml 24.3mM / L HAuCl 4 Add the aqueous solution to 50-200 ml of distilled water, then add 0.75-3 ml of 34.3 mM / L sodium citrate aqueous solution, add 0.5-3 ml of 0.1 M / L sodium borohydride aqueous solution under stirring conditions, and stir overnight to obtain about 3 nm of gold nanoparticles;

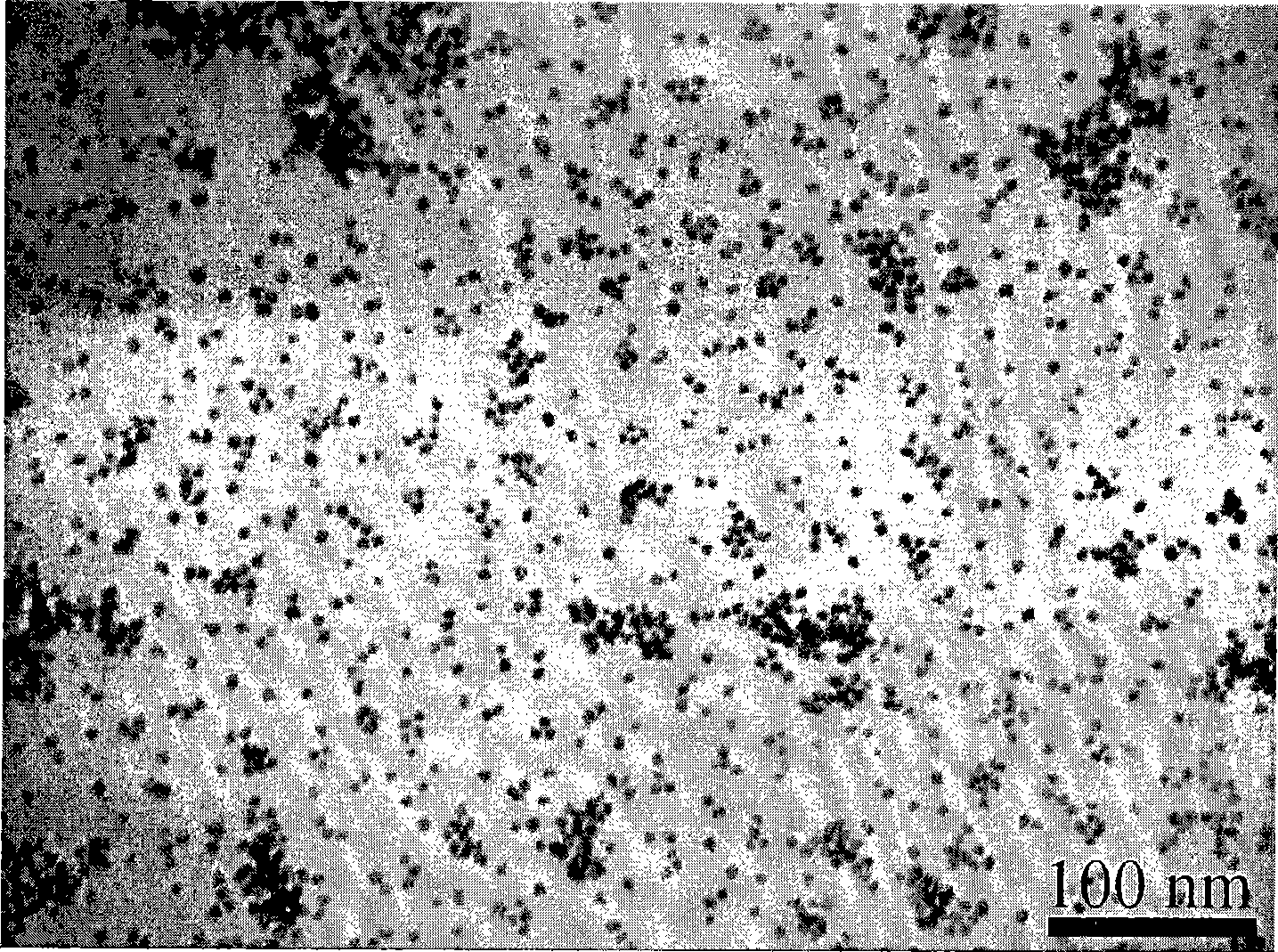

[0022] b, with the gold nanoparticles obtained above as seeds, with 0.1M / L ascorbic acid as green reducing agent, with 19.3mM / L H 2 PtCl 6 As a platinum source, the molar ratio of platinum to gold is 2:1, 0.1M / L ascorbic acid and 19.3mM / L H 2 PtCl 6 The volume ratio is 0.8-2, and heated at 100° C. for 15 minutes to obtain monodisperse flower-shaped gold / platinum hybrid nanoparticles with a particle size of about 6 nanometers.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com