Inner pot of electric cooker and electric cooker using the inner pot of electric cooker

An electric rice cooker and inner pot technology, applied in the field of electric rice cookers, can solve the problems of whitening, heat consumption, slow cooking temperature curve, etc., and achieve the effects of solving the bubbling and whitening, suppressing heat release, and improving the efficiency of cooking rice.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

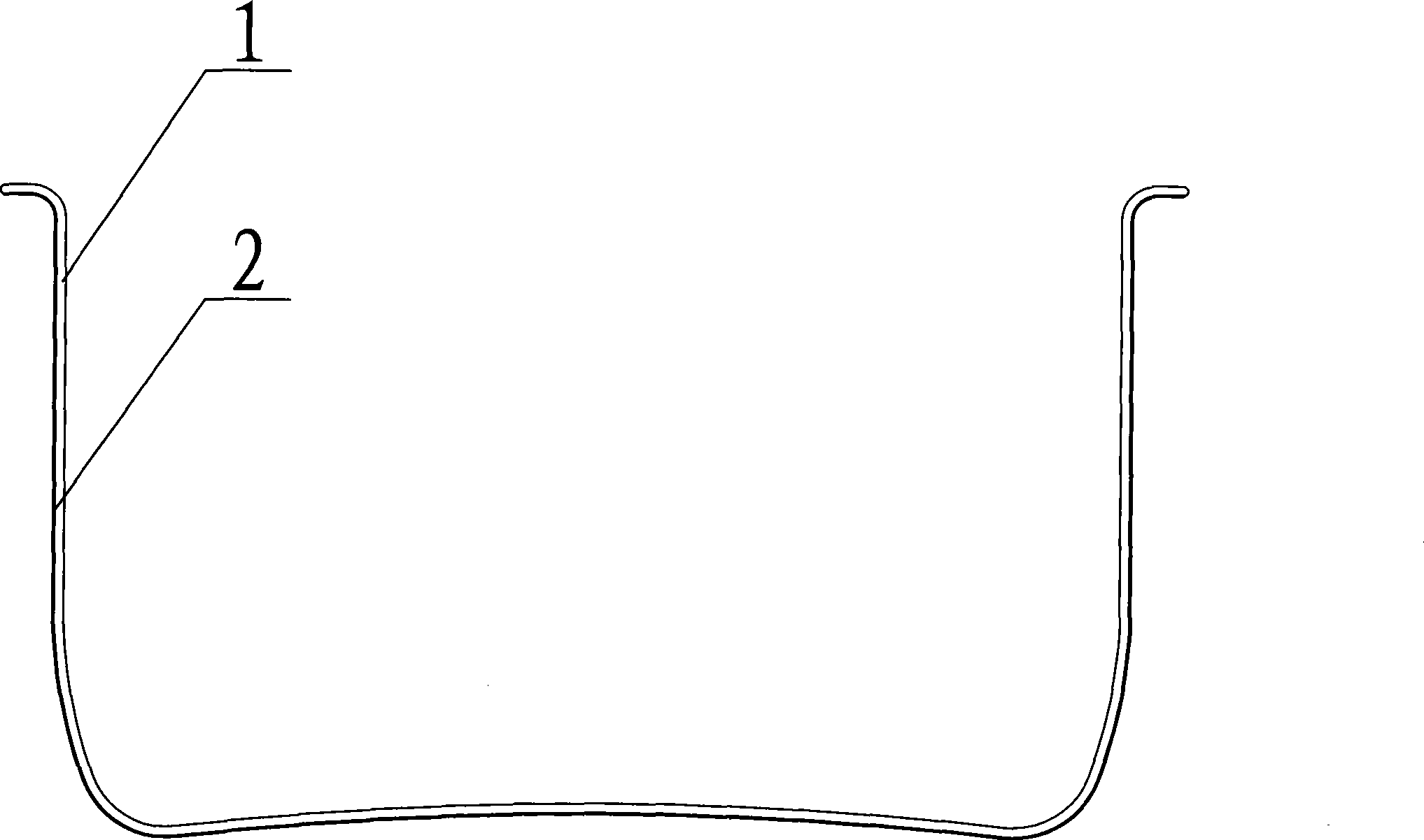

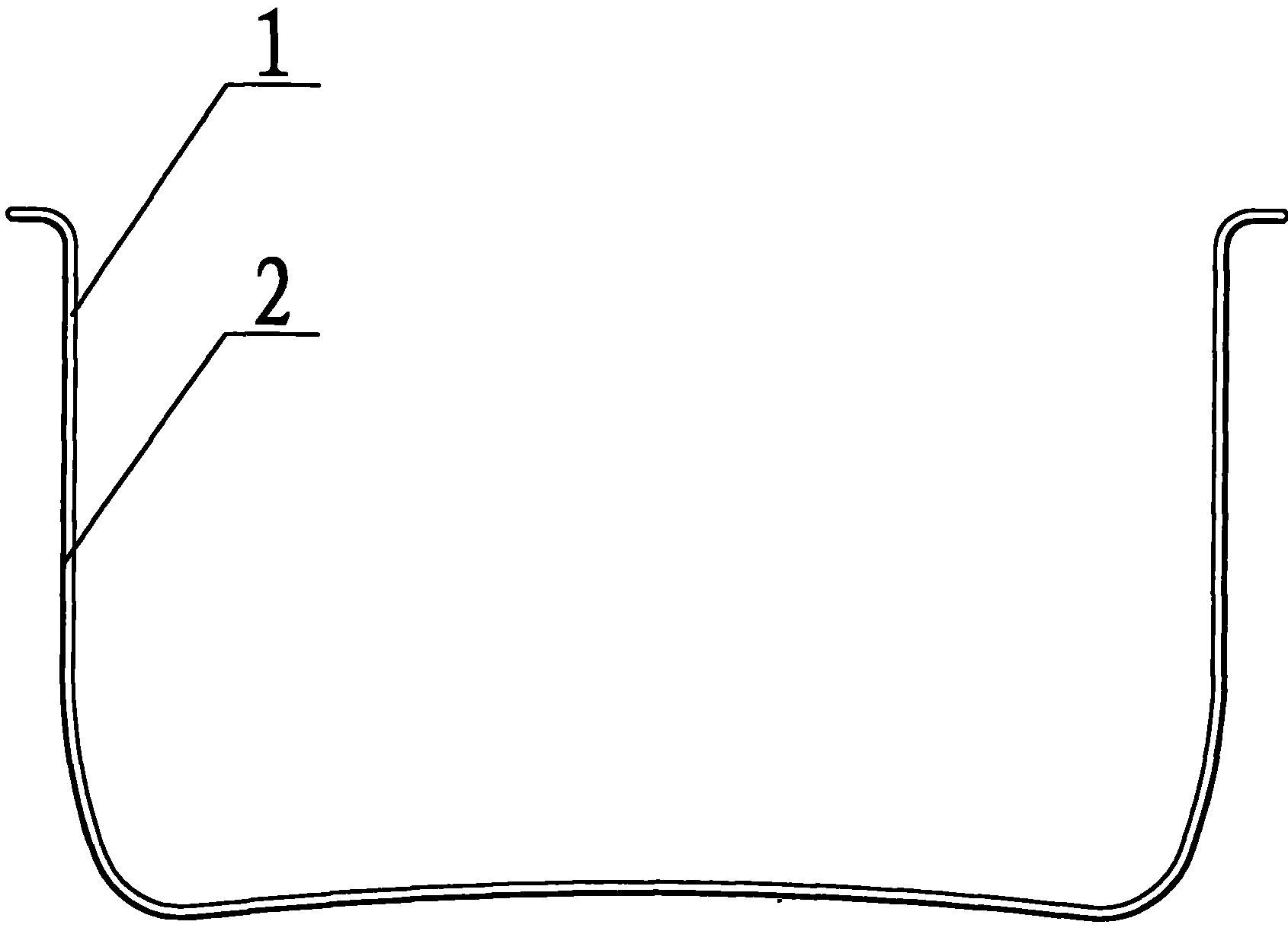

[0012] refer to figure 1 , The inner pot of the electric rice cooker includes an inner layer with high thermal conductivity and one or more outer layers with low thermal conductivity, and the thermal conductivity of multiple outer layers decreases sequentially from the inside to the outside. Preferably, the outer layer is generally one layer, which not only has a simple structure, but also can achieve the effect of suppressing the heat release of the pot. The outer layer is made of stainless steel, and the inner layer is made of aluminum. Stainless steel materials have a wide range of sources, low cost, and good wear resistance. The sum of the thickness of the inner layer and the outer layer is 1.8mm-2.2mm, and the thickness of the inner layer is greater than or equal to the thickness of the outer layer. The thickness of the inner layer is 1.9mm, and the thickness of the outer layer is 0.3mm. The pot body with a total thickness of about 2mm is more suitable for heat conduct...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com