Electromagnetic heating micro-forming method and apparatus used for non-magnetic workpiece

A micro-forming, non-magnetic technology, applied in induction heating devices, induction heating, induction heating control and other directions, can solve the problems of non-magnetic workpiece heating, heating application range, limitations, etc., to achieve simple structure, low use and maintenance costs , The effect of the control circuit is safe and reliable

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

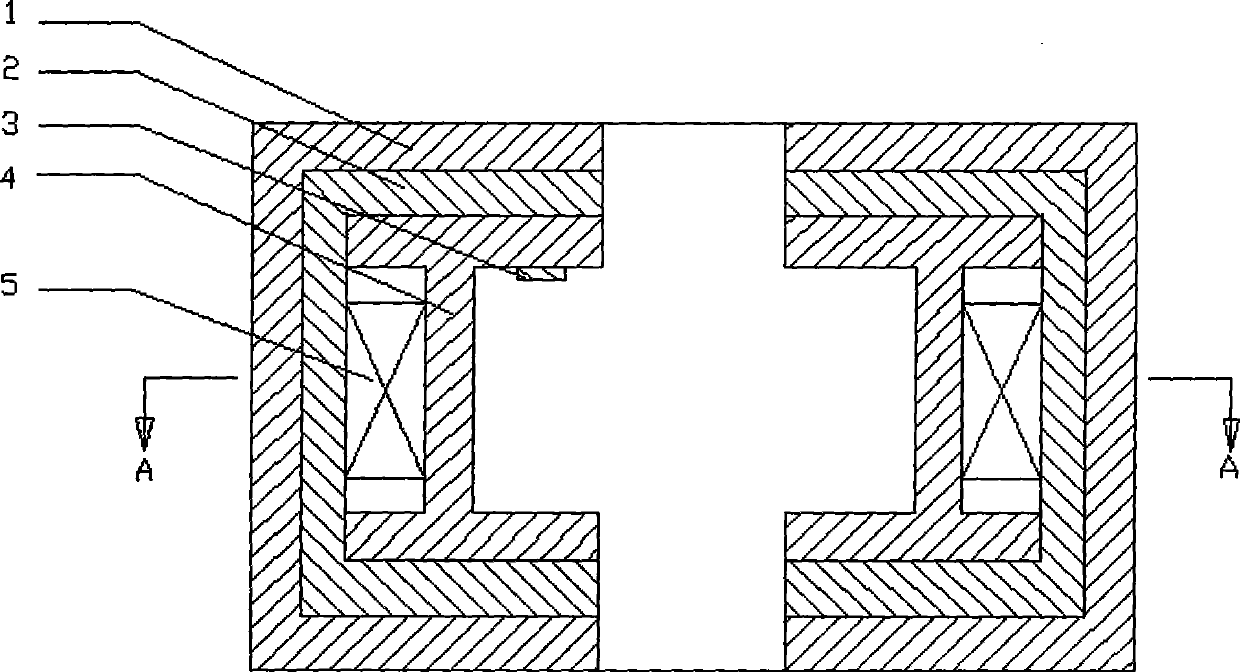

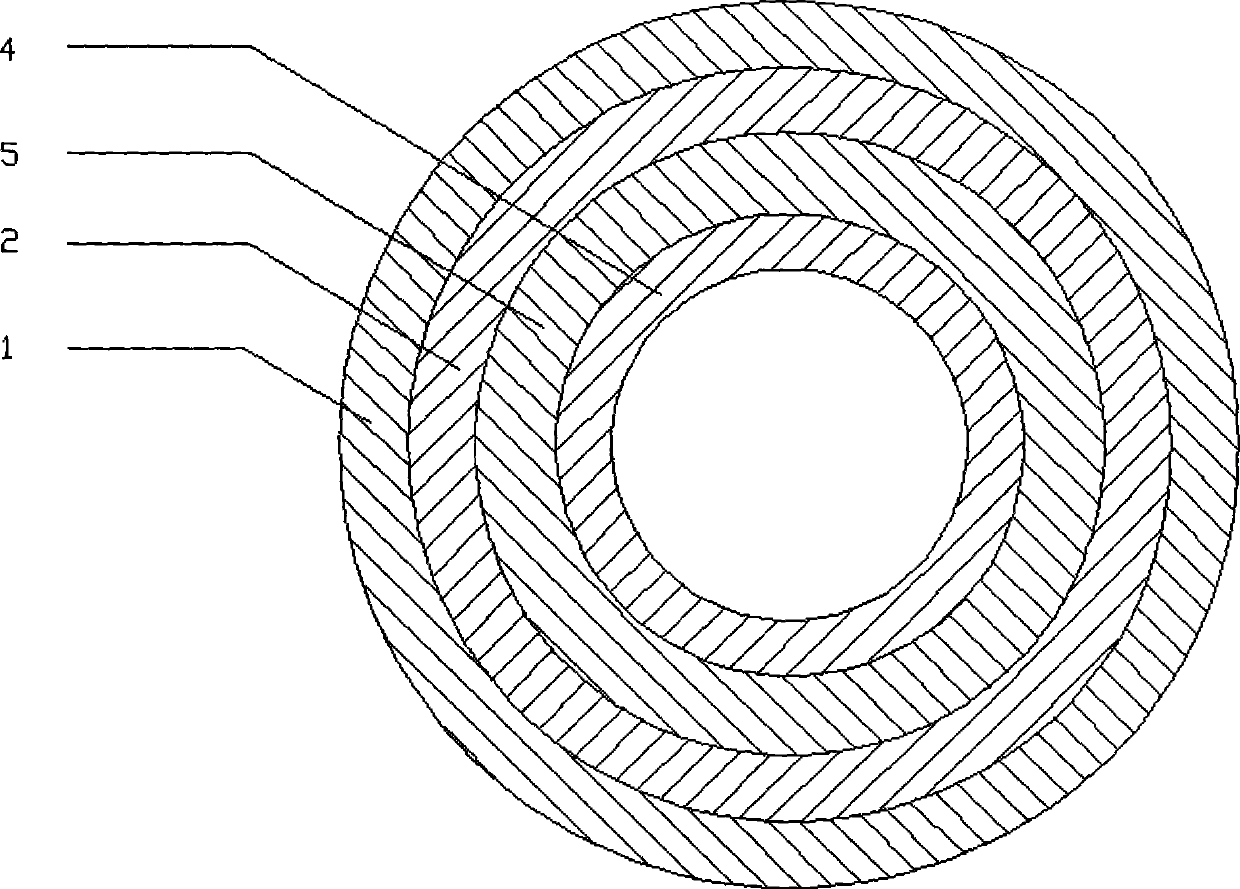

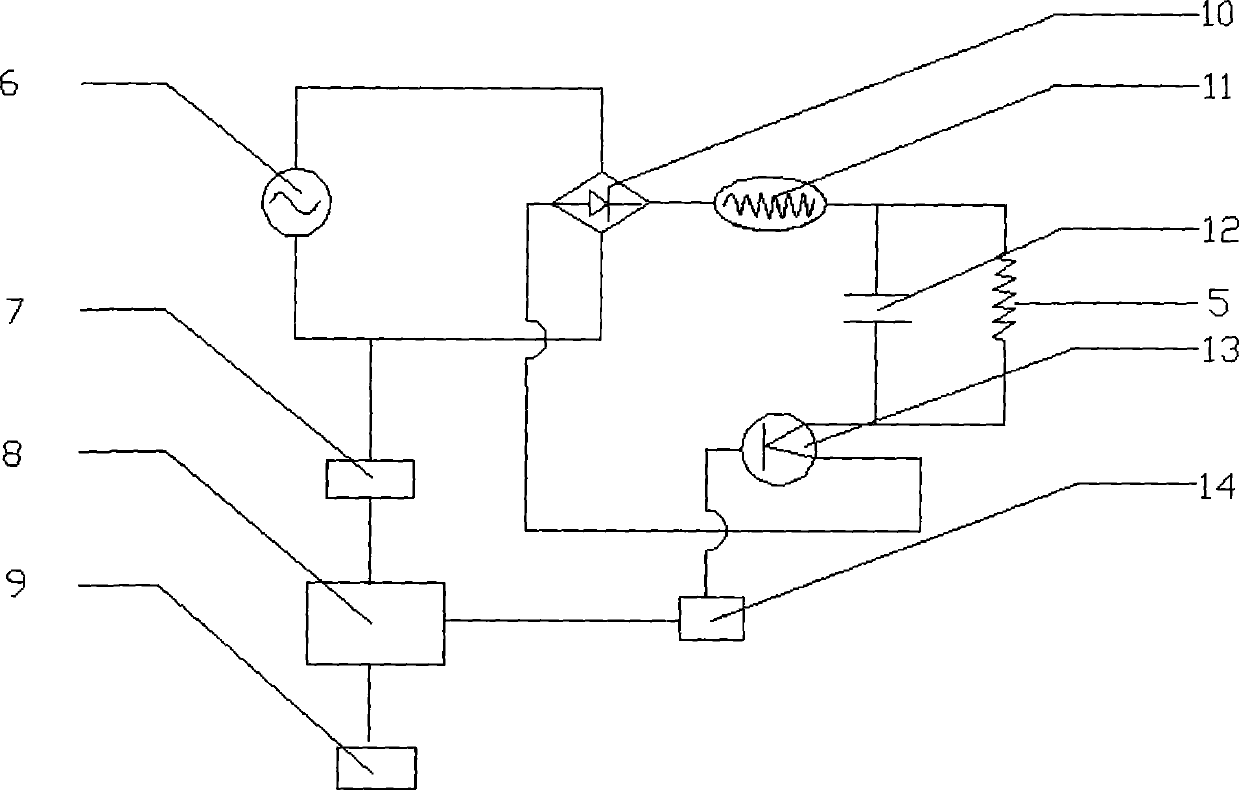

[0020] Combine below figure 1 , figure 2 , image 3 Be specific.

[0021] like figure 1 Shown is the main cross-sectional view of a microplastic forming device for non-magnetic workpieces that cannot be electromagnetically heated by direct heat transfer between objects. The workpiece is a non-magnetic workpiece that cannot be electromagnetically heated through direct heat transfer between objects. The center of the device is a heating cavity with upper and lower through holes, narrow at both ends, and wide in the middle. From the inside to the outside, there are magnetic metal (magnetic core) 4, electric The magnetic induction coil 5, the electromagnetic shielding magnetic block 2, the insulating heat shield 1, and the temperature detection element 3 are arranged on the inner surface of the magnetic core close to the workpiece. When working, the fixture connecting the workpiece will position the workpiece in the middle of the heating cavity through the upper and lower thr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com