Product quality prediction technique for recombination assembly line

A technology of product quality and prediction method, applied in the direction of comprehensive factory control, comprehensive factory control, electrical program control, etc., can solve the problems of many variables, large amount of data, difficult analysis and so on

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

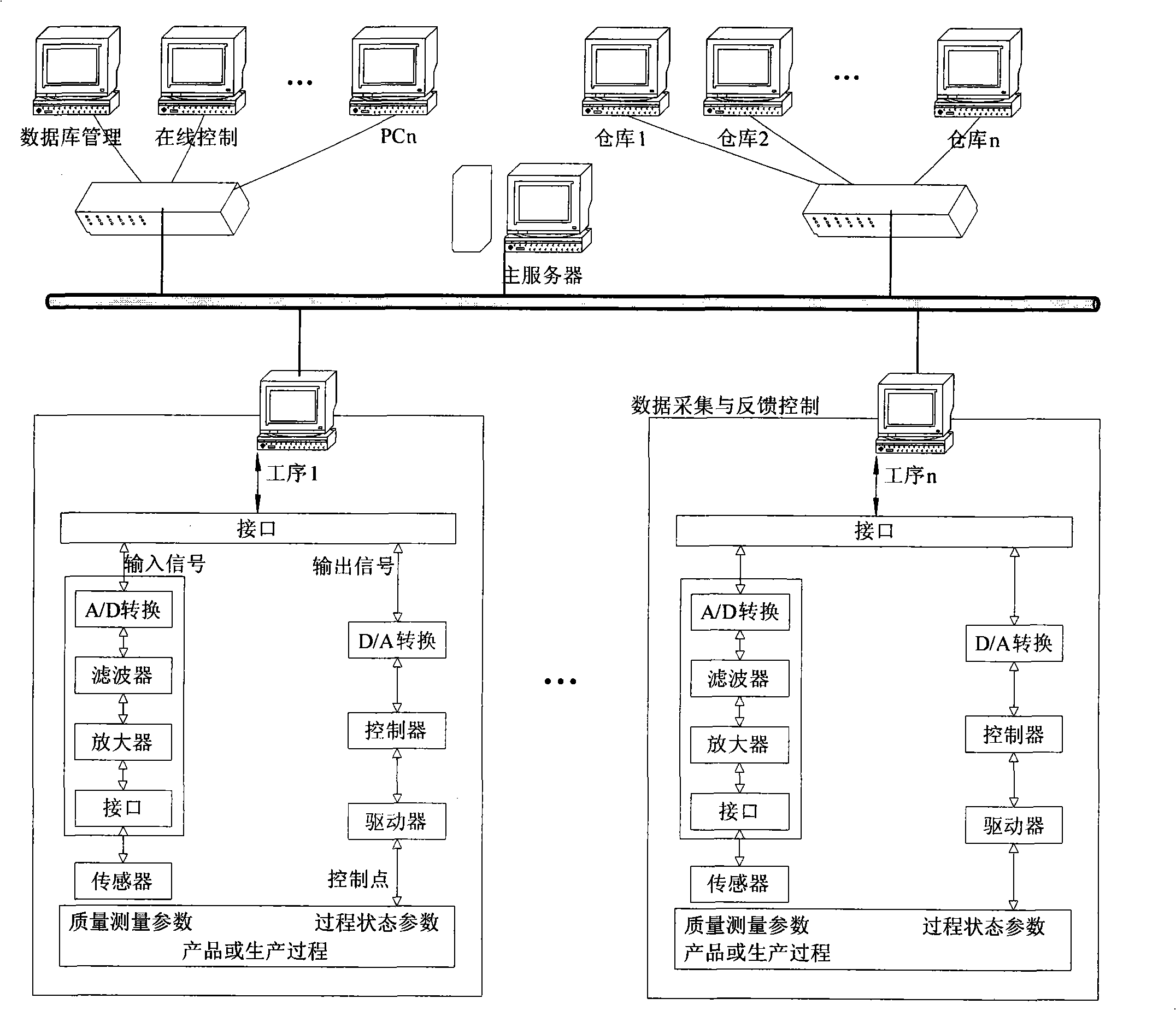

[0026] The present invention is realized through the following technical solutions, the hardware system of the production line is as figure 1 As shown, it mainly includes production line control system and sensor data acquisition system.

[0027] (1) The production line control system adopts a distributed network control system. This system structure can be generally divided into three levels: on-site execution layer, analysis control layer and planning decision-making layer. It has the following characteristics:

[0028] Because the distribution of the physical location of the process is discrete, the distributed control network makes them organically form a whole in order to share data and exchange information.

[0029] In order to effectively organize a large amount of quality data and establish a standard data exchange interface, a database should be used for storage and management.

[0030] The collection of process quality data is real-time. Multiple process quality co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com