Load-sensitive and logical double-pump switching valve structure

A load-sensitive switching valve technology, applied in the field of hydraulic valves, can solve the problems of increasing manufacturing costs, increasing the complexity of linkage control, and being unfavorable for popularization, and achieves the effects of reasonable design principles, convenient loading, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

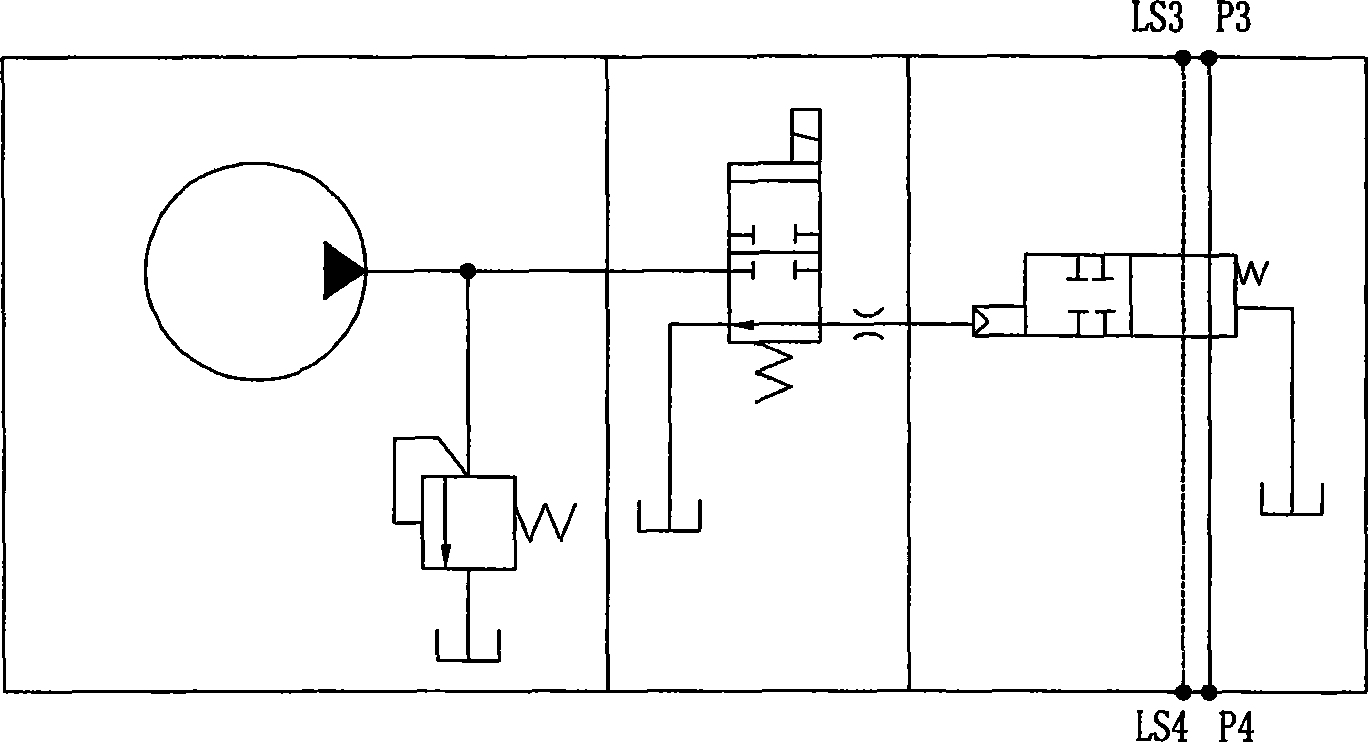

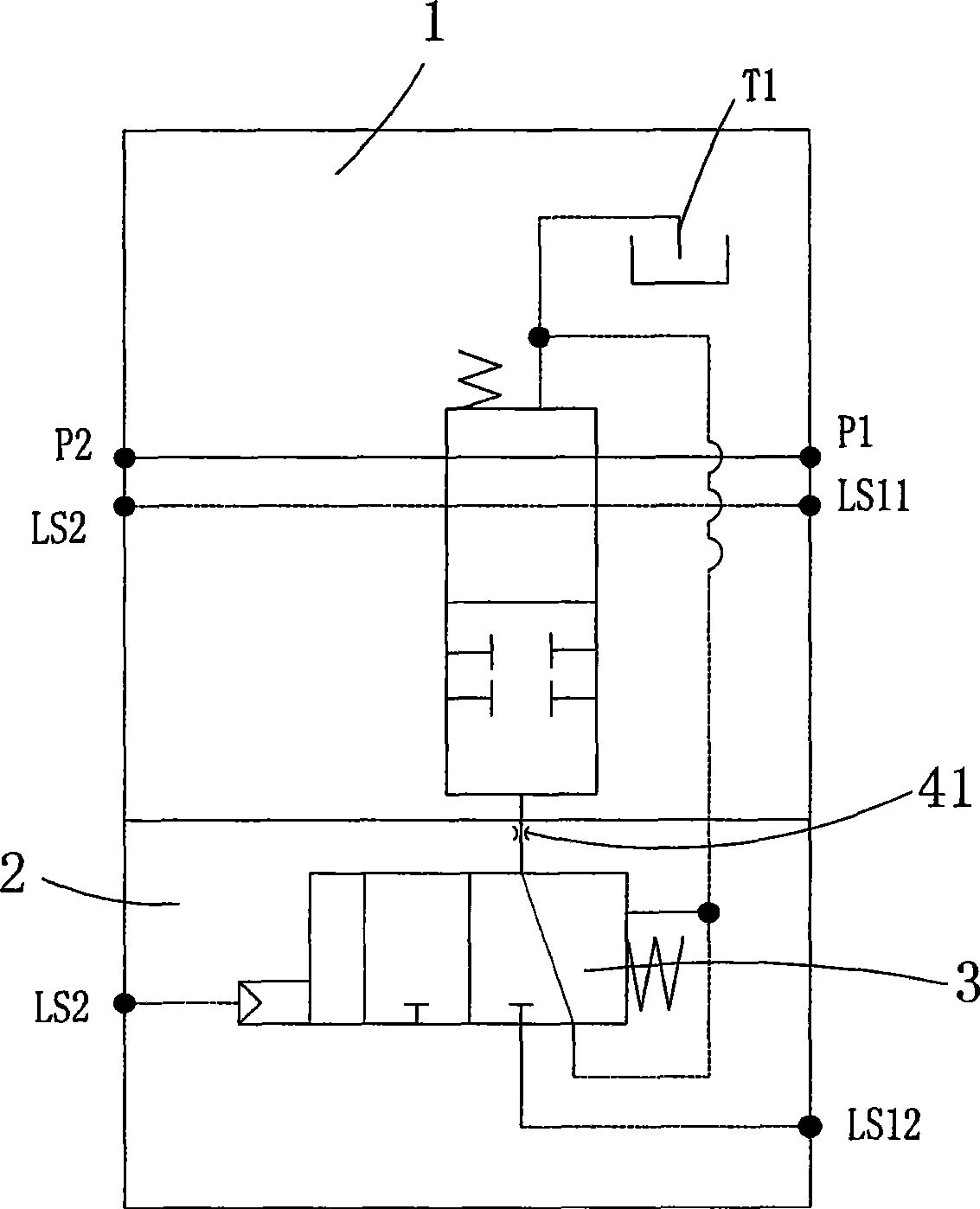

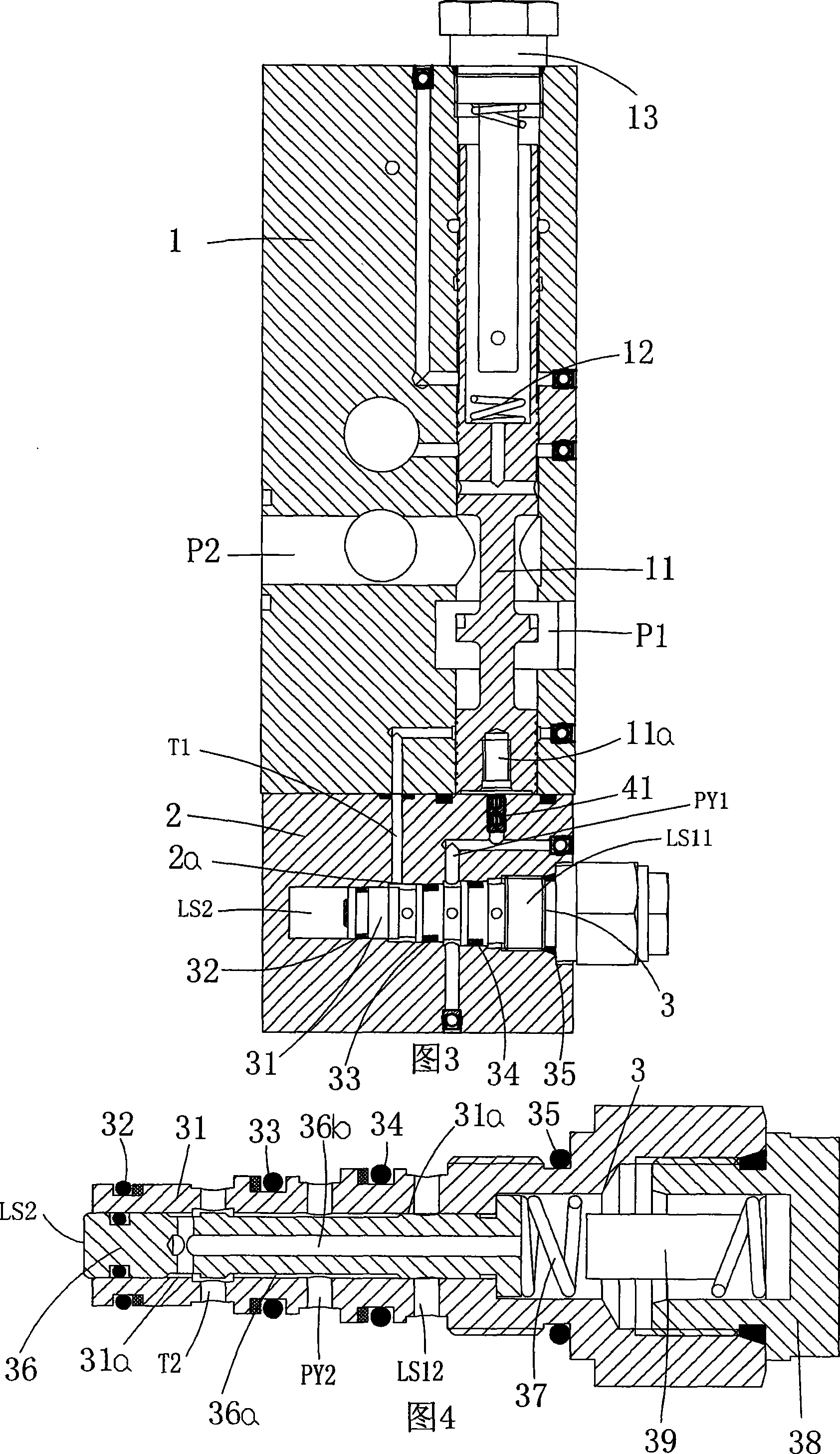

[0026] Such as figure 2 As shown in Figure 6, the reference numbers are as follows: the first valve body 1, the switching valve core 11, the hydraulic control chamber 11a, the first spring 12, the screw plug 13, the second valve body 2, the first slideway hole 2a, the logic Valve 3, valve sleeve 31, second slideway hole 31a, first sealing ring 32, second sealing ring 33, third sealing ring 34, fourth sealing ring 35, logic valve core body 36, ring groove body 36a, middle Hole 36b, second spring 37, second spring seat 38, spring support seat 39, transition block 4, damper 41, first control spool 5, third spring 51, first drive chamber 52, first hydraulic control hole 53, the second control spool 6, the fourth spring 61, the second drive chamber 62, the second hydraulic control hole 63, the main control port LS1, the first input control port L...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com