Step type bed-pan equipped with horizontal siphons

A stepped and siphon tube technology, applied in water supply devices, flushing toilets, buildings, etc., can solve problems such as poor integrity, large pelvic volume, and difficulty in producing qualified products, and achieve simplified and firm skirt structure, enhanced siphon function, and convenience The effect of production operations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

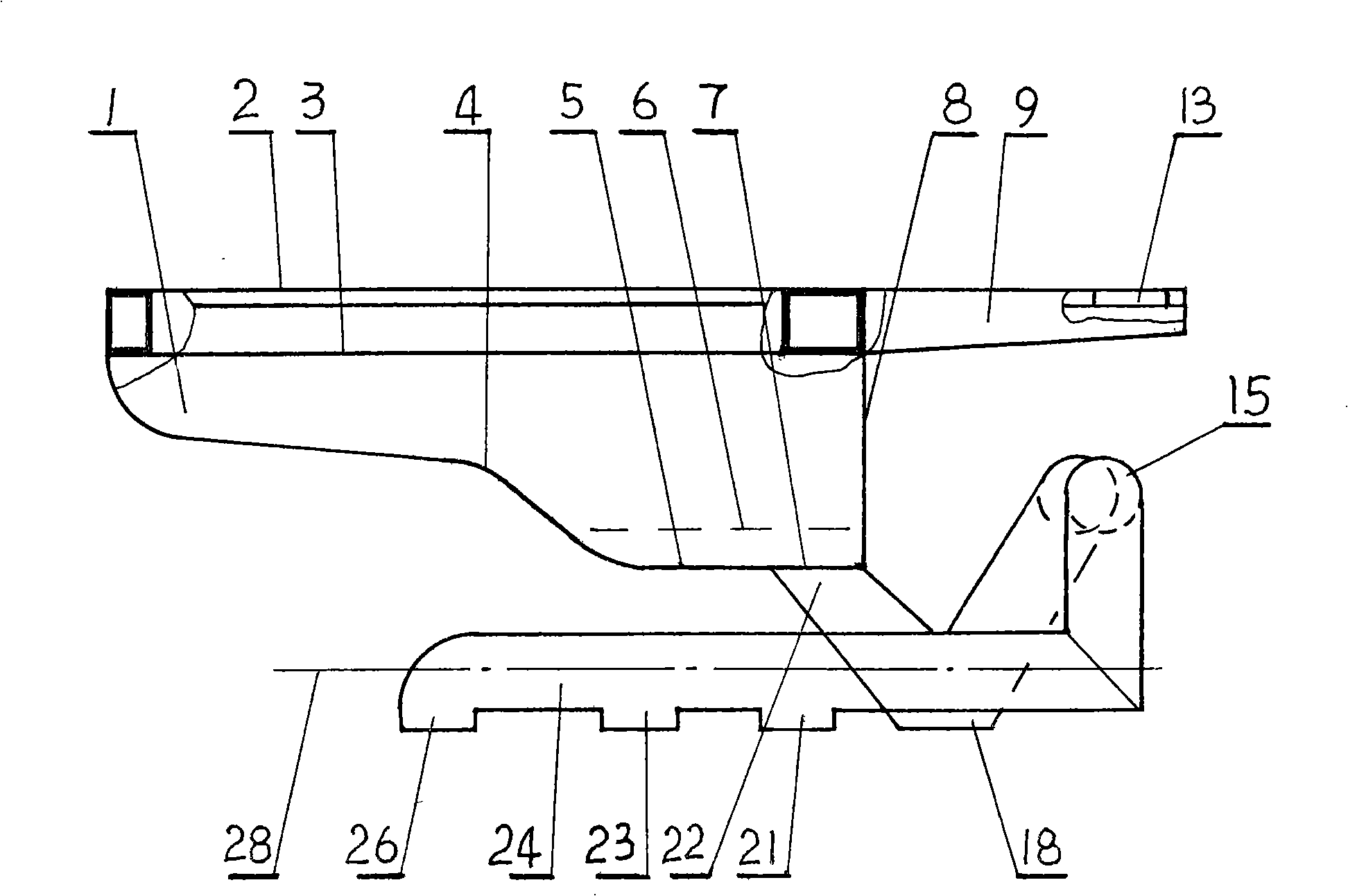

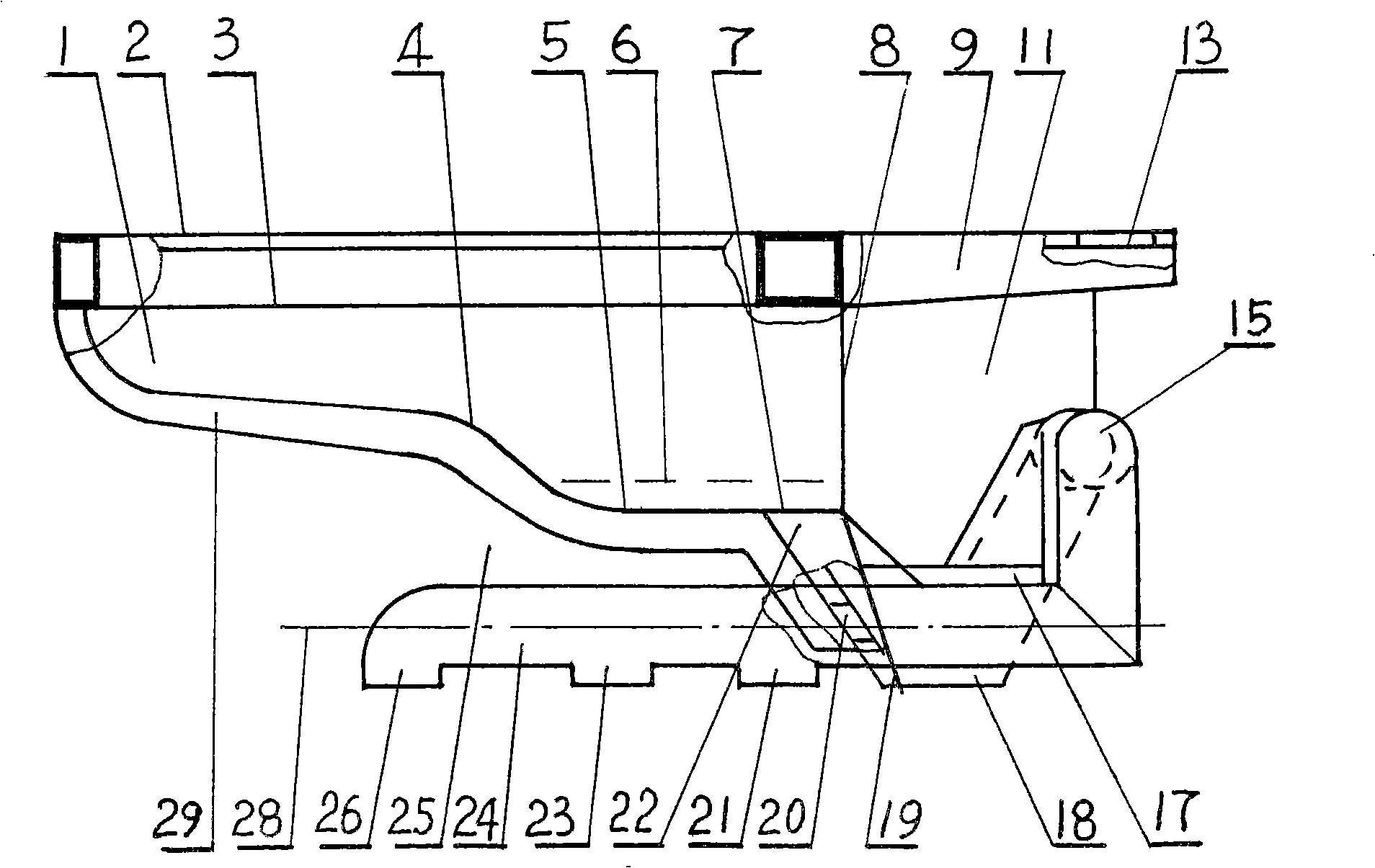

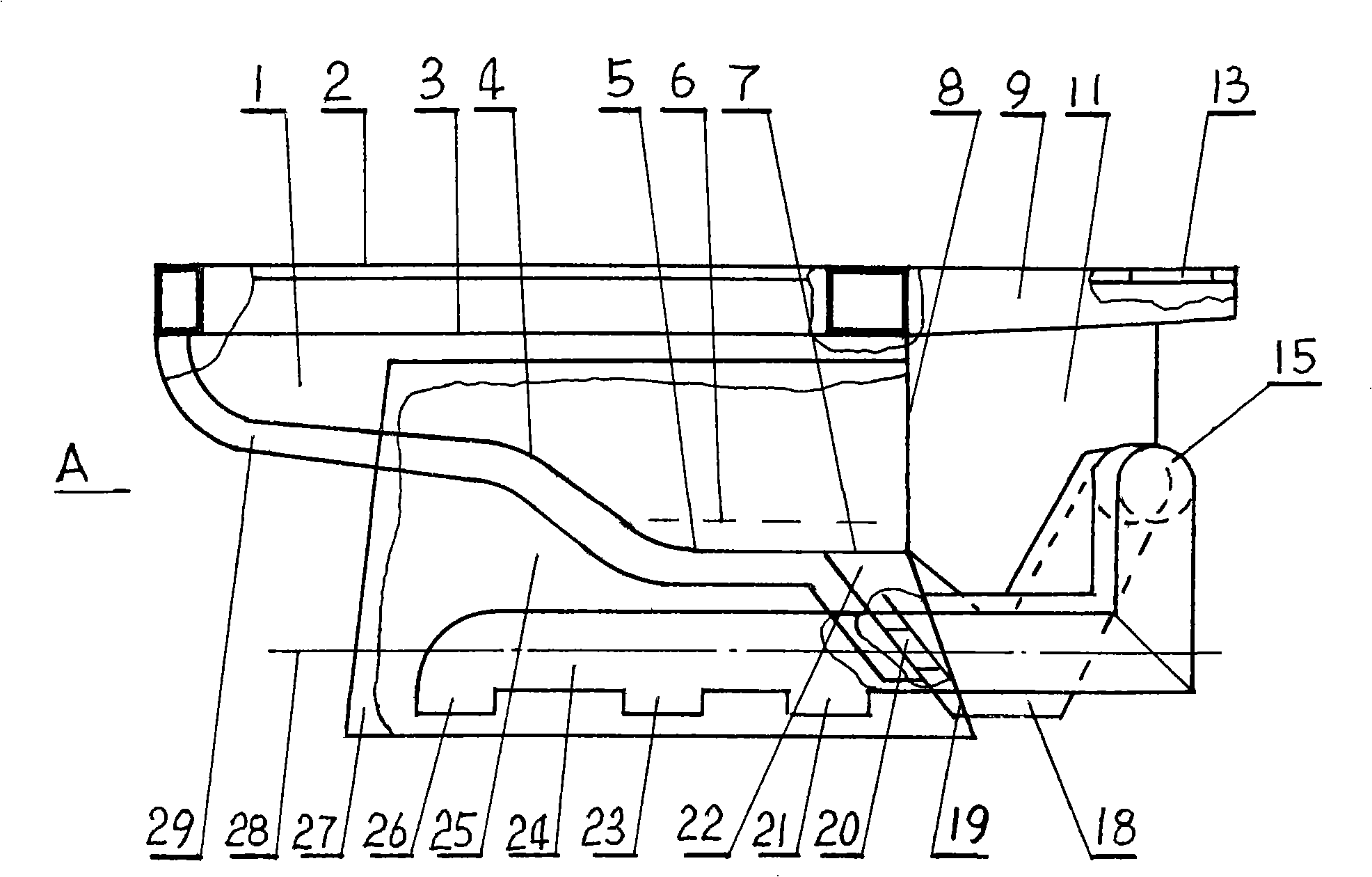

[0022] Such as figure 1 , figure 2 , Figure 5 As shown, the stepped bedpan equipped with a horizontal siphon in this embodiment includes a horizontal siphon 22 arranged at the lower rear end of the stepped bedpan 1 . Wherein, the stepped bedpan 1 includes a water ring 2, a water channel 9, a pelvic step 4, and a funnel bottom 5. The back end of the water circle 2 of the stepped bedpan 1 is connected to the water channel 9, and the rear end of the water channel 9 is provided with a flushing water inlet 13, and a pelvic step 4 is set at the middle position of the stepped bedpan 1 to the upper edge 3 of the front end of the pelvic cavity, and the pelvic cavity step 4 The bottom of the funnel pelvis 5 is formed by delaying and slanting downwards, and the bottom of the funnel pelvis 5 and the pelvic cavity steps 4 form an oblong two-step pelvic floor. Horizontal siphon, wherein: includes a V-shaped water-sealed lower elbow 18, a horizontal elbow 15, and a drain main pipe 24. ...

Embodiment 2

[0024] Such as figure 1 , figure 2 , Figure 5 , Figure 6 As shown, the stepped bedpan equipped with a horizontal siphon in this embodiment is based on the embodiment 1 and is provided with an additional water channel 29 outside the bottom of the stepped bedpan 1, and the upper end of the attached water channel 29 is connected to the water circle 2 , the lower end is connected with the injection hole 20 provided on one side of the bottom tube wall of the V-shaped water-sealed lower elbow.

Embodiment 3

[0026] Such as figure 1 , figure 2 , Figure 5 , Figure 6 As shown, it includes the above-mentioned stepped bedpan equipped with a horizontal siphon, wherein: it also includes a vertical rib plate 11 connected to the lower end surface of the V-shaped water-sealed lower elbow 18 outer diameter middle water channel 9, and the inner side of the vertical rib plate 11 The horizontal curved pipe 15, the angular rib plate 17 provided on the upper end of the drain main pipe 24, and the funnel basin bottom 5 rear wall form a box-like structure that expands to one side. Rib 25.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com