Plasma surface cleaning apparatus

A surface cleaning and plasma technology, used in cleaning methods and utensils, chemical instruments and methods, etc., can solve the problems of easy formation of water stains, easy shedding of thin films, easy shedding of coating layers, etc., to improve surface cleanliness and avoid two Less polluting, versatile effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] In this embodiment, wet cleaning and ion cleaning are combined, that is, wet cleaning is performed first, and then plasma cleaning is performed, so that the cleaning effect is better, the surface cleanliness of the plated parts is high, the quality of the coated film layer is good, and the adhesion is strong. long life.

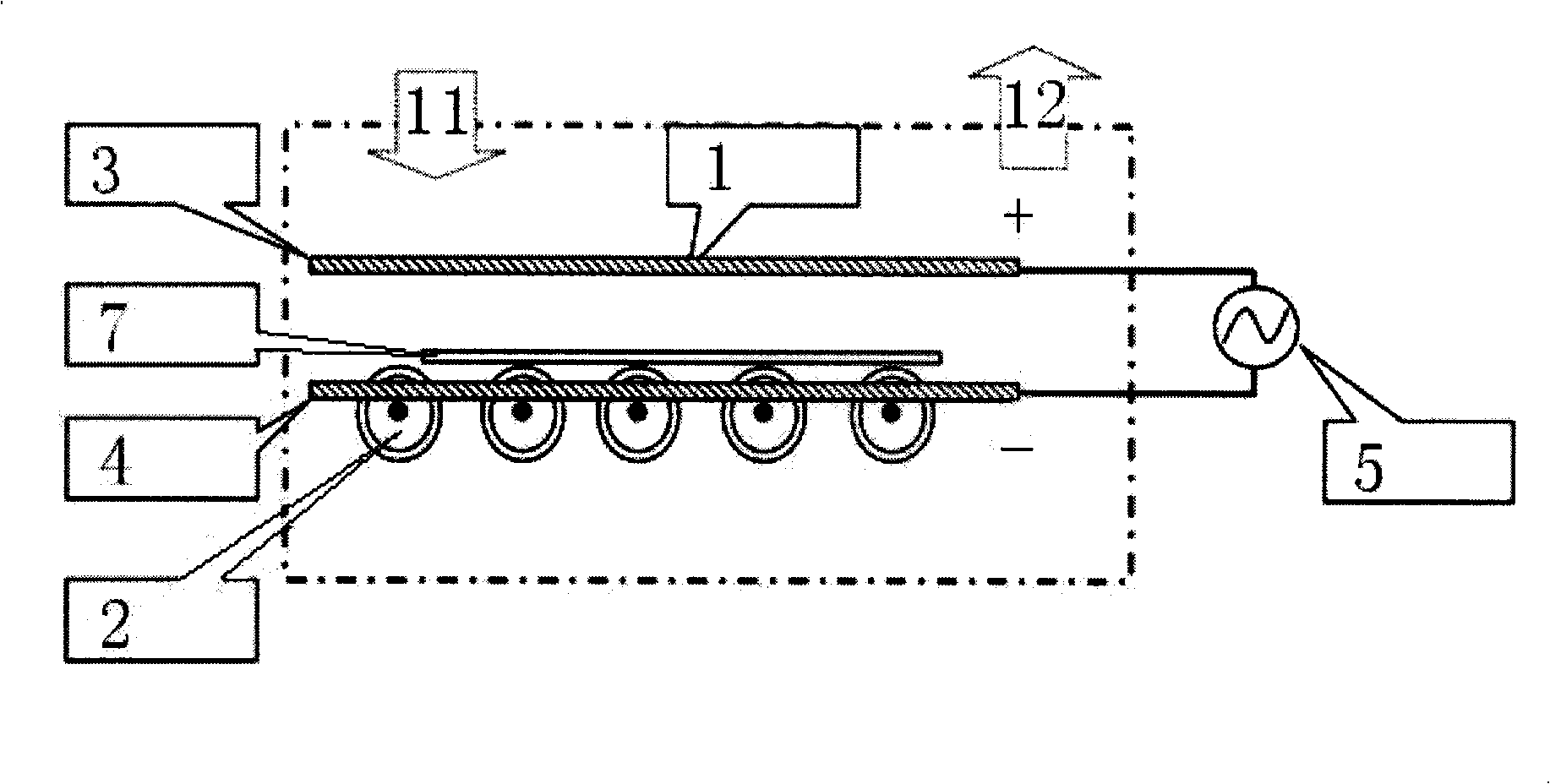

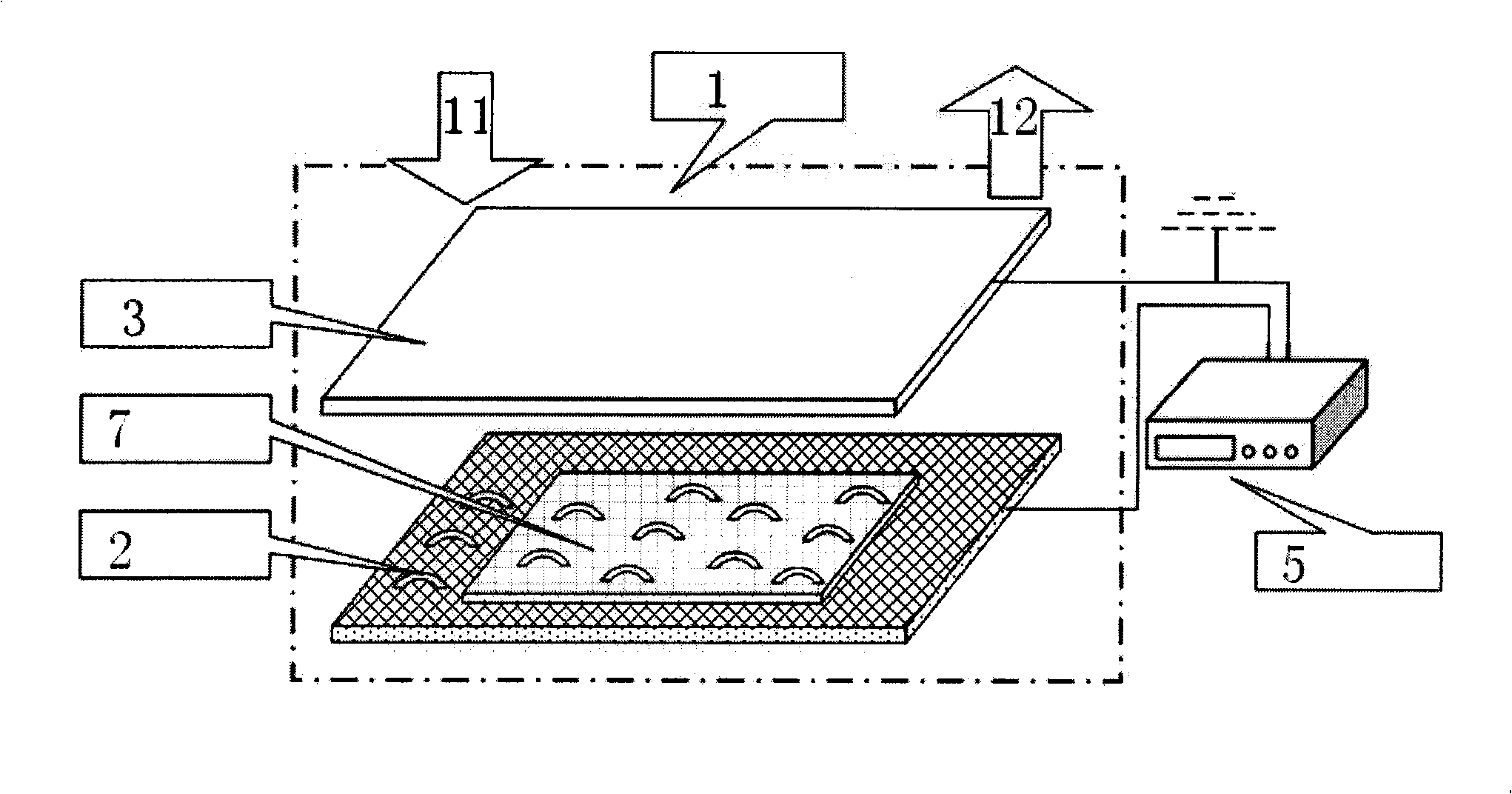

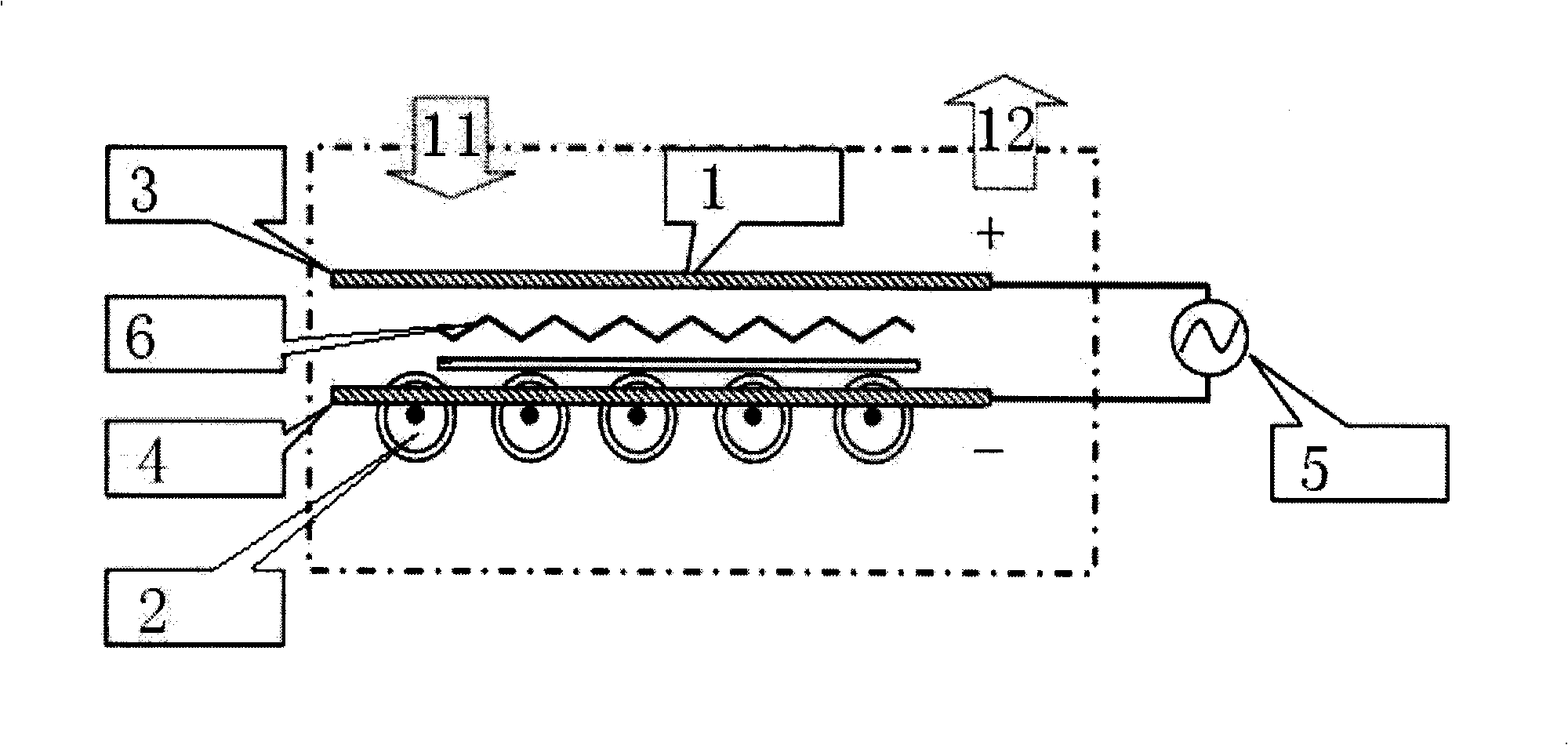

[0026] Such as figure 1 , figure 2 and image 3 As shown, the device for plasma surface cleaning in this embodiment includes a vacuum chamber 1 with an air inlet 11 and an air extraction port 12 opened thereon. A transfer roller 2 is installed in the vacuum chamber 1 . The glass substrate (plated piece) 7 to be cleaned is placed on the transfer roller 2 . A pair of metal plates 3, 4 are mounted on the upper and lower sides of the conveying roller 2 respectively, and the pair of metal plates 3, 4 are respectively connected to the positive and negative poles of a bias power supply 5. The bias power supply 5 can be a direct current or an intermediat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com