Flue gas desulfurization technique of return current circulating fluidized bed in flow equalizing field

A circulating fluidized bed and internal recirculation technology, applied in membrane technology, gas treatment, chemical instruments and methods, etc., can solve the problems of high dust concentration of outlet flue gas, heavy load of bag filter, uneven flow field, etc. Achieve the effect of ensuring desulfurization efficiency, reducing load and solving technical problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

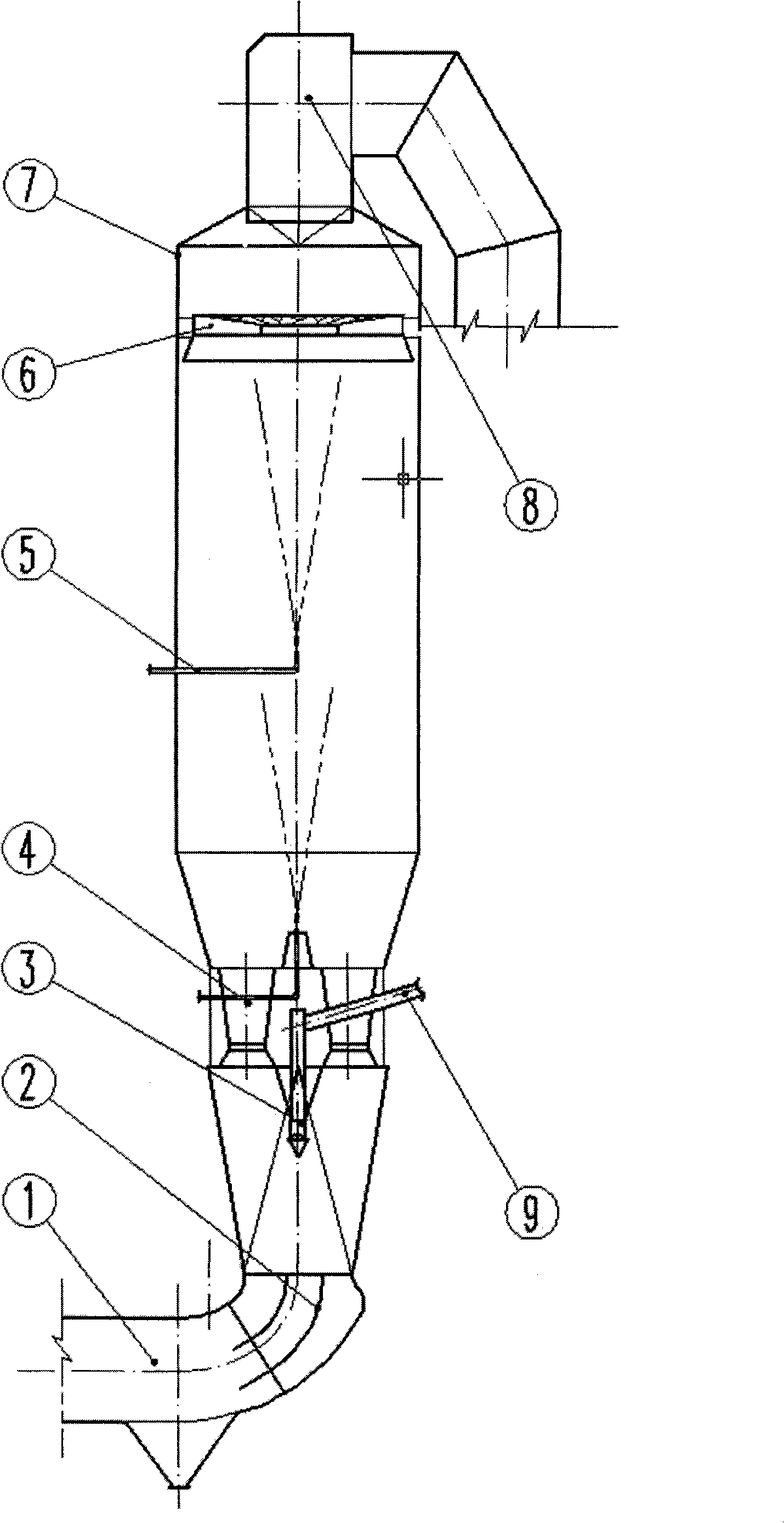

[0016] see figure 1 , the core equipment of "reflux circulating fluidized bed flue gas desulfurization technology in the flow equalization field" - the reactor, its structure from bottom to top is: direct current streamlined bottom air inlet 1, deflector 2, central built-in absorption Agent distributor 3, flue gas accelerator 4, humidification and activation nozzle 5, swirl plate gas-solid separator 6, central outlet flue 8 on the upper part of reactor cylinder 7, and connection with central built-in absorbent distributor 3 Slaked lime and recycled ash inlet channel 9. The humidifying and activating nozzle 5 adopts a two-stage two-fluid nozzle and is located at the center of the reactor. The deflector 2 as a part of the intake mechanism is a double-arc evenly distributed deflector. The flue gas accelerator 4 is a "Laval nozzle" type flue gas accelerator.

[0017] The direct current streamlined bottom air intake flue, the double-arc evenly distributed deflector and the centr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com