Mechanical-hydraulic guiding virtual displacement variable hydraulic transformer and variable method

A technology of hydraulic transformers and virtual displacements, which is applied to physical quantity changers, fluid pressure converters, mechanical equipment, etc., and can solve problems such as low overall efficiency, instability, and narrow variable ranges

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

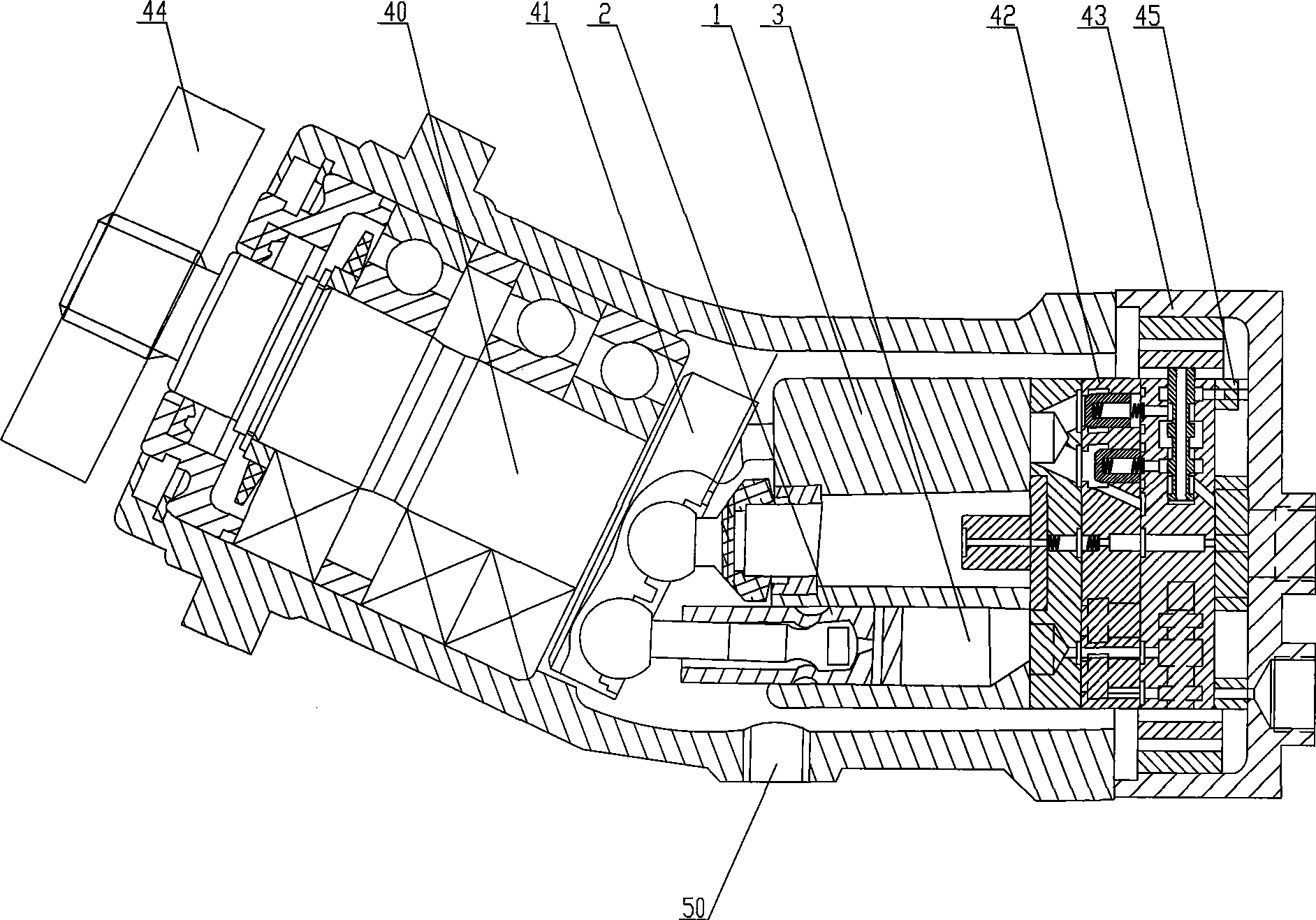

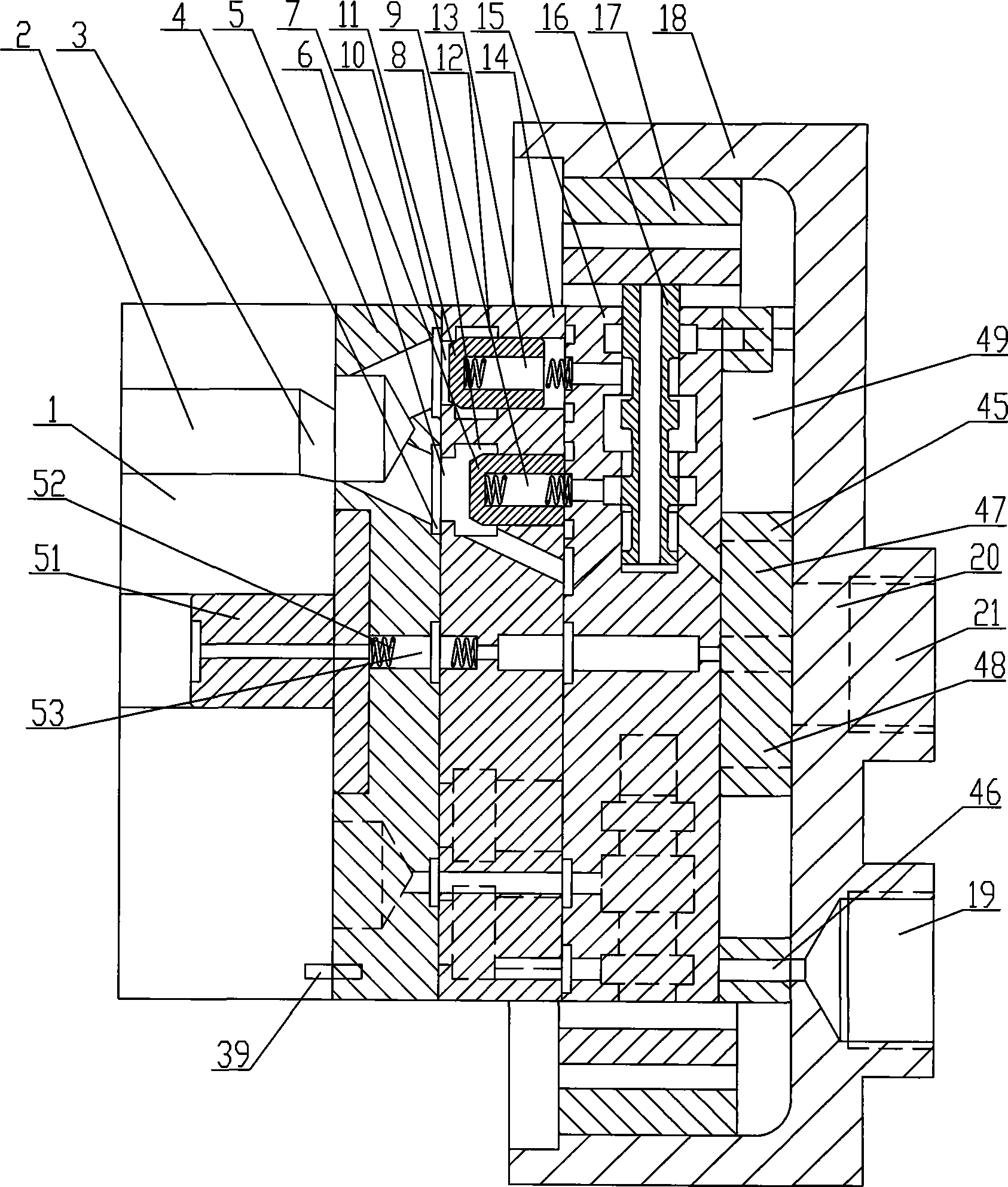

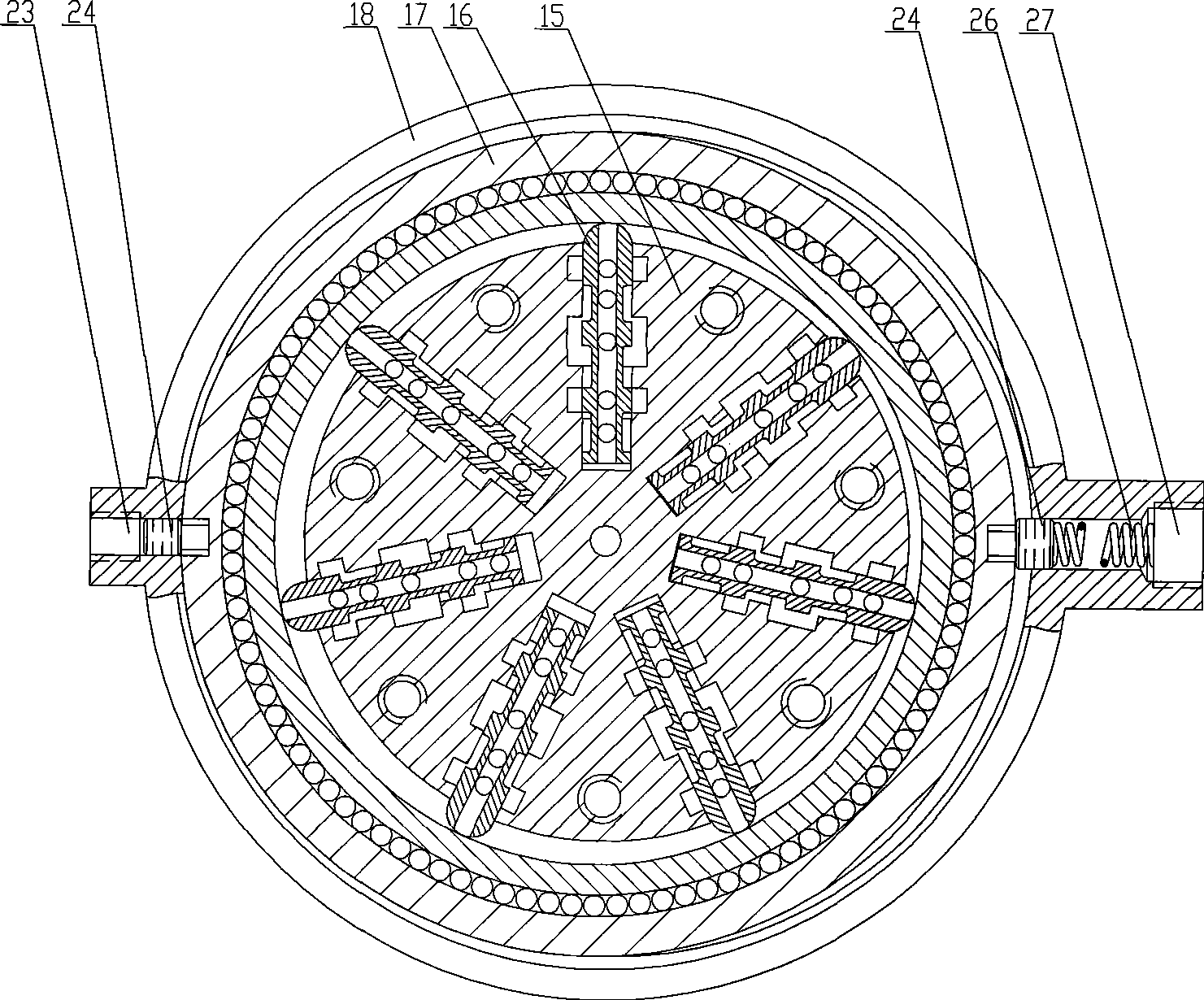

[0062] In conjunction with the accompanying drawings, the present invention will be described in detail below through specific embodiments.

[0063] In this specific embodiment, a machine-hydraulic pilot virtual displacement variable hydraulic transformer is refitted from an ordinary rotary cylinder-type quantitative plunger hydraulic motor.

[0064] Install a flywheel with a large moment of inertia on the output shaft of the plunger type quantitative hydraulic motor as a torque filter mechanism; remove the back cover and oil distribution plate of the hydraulic motor at the same time, process the end face of the plunger cylinder into a plane, and A pin hole is processed between every two plunger cavities of the plunger cylinder, and the position of the pin hole is consistent with that of the oil distribution valve body in the present invention. The oil distribution assembly of the present invention is installed on the original rear cover and oil distribution plate position of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com