Polychloroethylene ultraviolet light stabilizer, light resistant polychloroethylene and preparation method

A polyvinyl chloride and light stabilizer technology, applied in the polymer field, can solve the problems of poor compatibility of PVC substrates, high particle cost, insufficient light stabilization efficiency, etc., to improve compatibility, improve product mechanics, UV light good protective effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

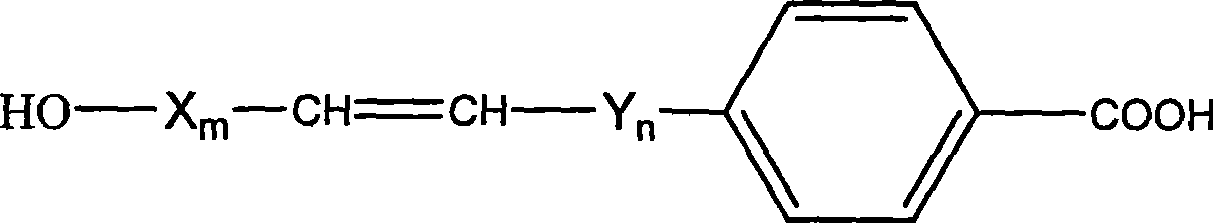

Method used

Image

Examples

Embodiment 1

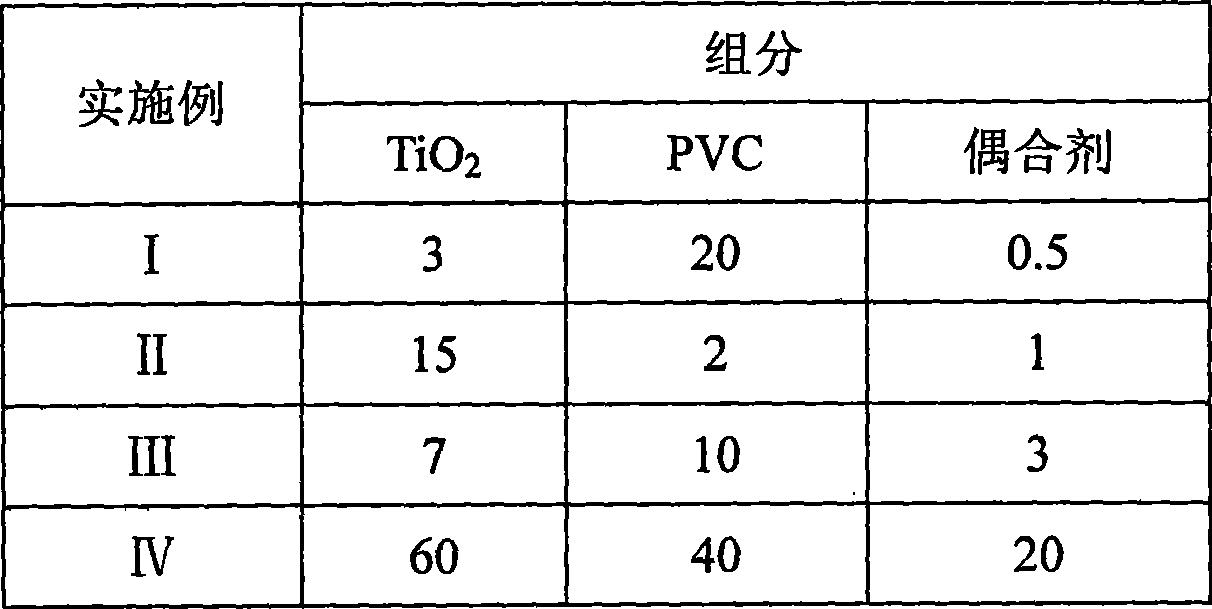

[0035] The preparation of ultraviolet light stabilizer embodiment 1: TiO 2 The particles are placed in a desiccator to dry for about 2 hours, and the pre-dried TiO 2 Particles, PVC resin and functional additive coupling agent are prepared according to a given ratio, mixed and placed in a high-energy vibration mill at 800 rpm, and mixed and vibrated for about 8 hours at about 30°C to obtain PVC UV light stabilizer.

Embodiment 2

[0037] The preparation of ultraviolet light stabilizer embodiment 4: TiO 2The particles are placed in a desiccator for drying treatment for about 1 hour, and the pre-dried TiO 2 Particles, PVC resin and functional auxiliary agent coupling agent are prepared according to a given ratio, mixed and placed in a high-energy vibrating mill at 600 rpm, and vibrating and milled for about 12 hours at about 20°C to obtain PVC UV light stabilizer.

[0038] The preparation methods of other examples are basically the same as those of the above examples.

[0039] Provide the embodiment and the test result of the light-resistant PVC containing the ultraviolet light stabilizer provided by the present invention below

[0040] Example 1:

[0041] Respectively 2.5phr, 5phr new ultraviolet light stabilizer I, 2phr organotin heat stabilizer, 0.5phr stearic acid are added in the PVC resin (PVC-SG8 of Yibin Tianyuan chemical factory) of 100phr, in the two-roll mixer Knead at about 170°C for about...

Embodiment 3

[0049] 2.0phr, 5phr novel light stabilizer III, 4phr organotin heat stabilizer, 0.8phr stearic acid are added in the PVC resin (PVC-SG8 of Yibin Tianyuan chemical factory) of 100phr respectively, in the two-roll mixer Mix at about 170°C for about 10 minutes, and then press at about 180°C to form sheets and plates of required thickness for performance testing after accelerated aging. (1#: Add 2.0phr content of TiO 2 PVC sample of composite particles; 2#: adding 5phr of TiO 2 PVC sample of composite particles)

[0050]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com