Vehicle wiper

A wiper and automobile technology, applied in vehicle maintenance, vehicle cleaning, transportation and packaging, etc., can solve problems such as damage to the wiper motor, large water spray volume, and large load on the wiper motor, so as to prolong the service life and prevent being wiped. Scratch, not easy to damage the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

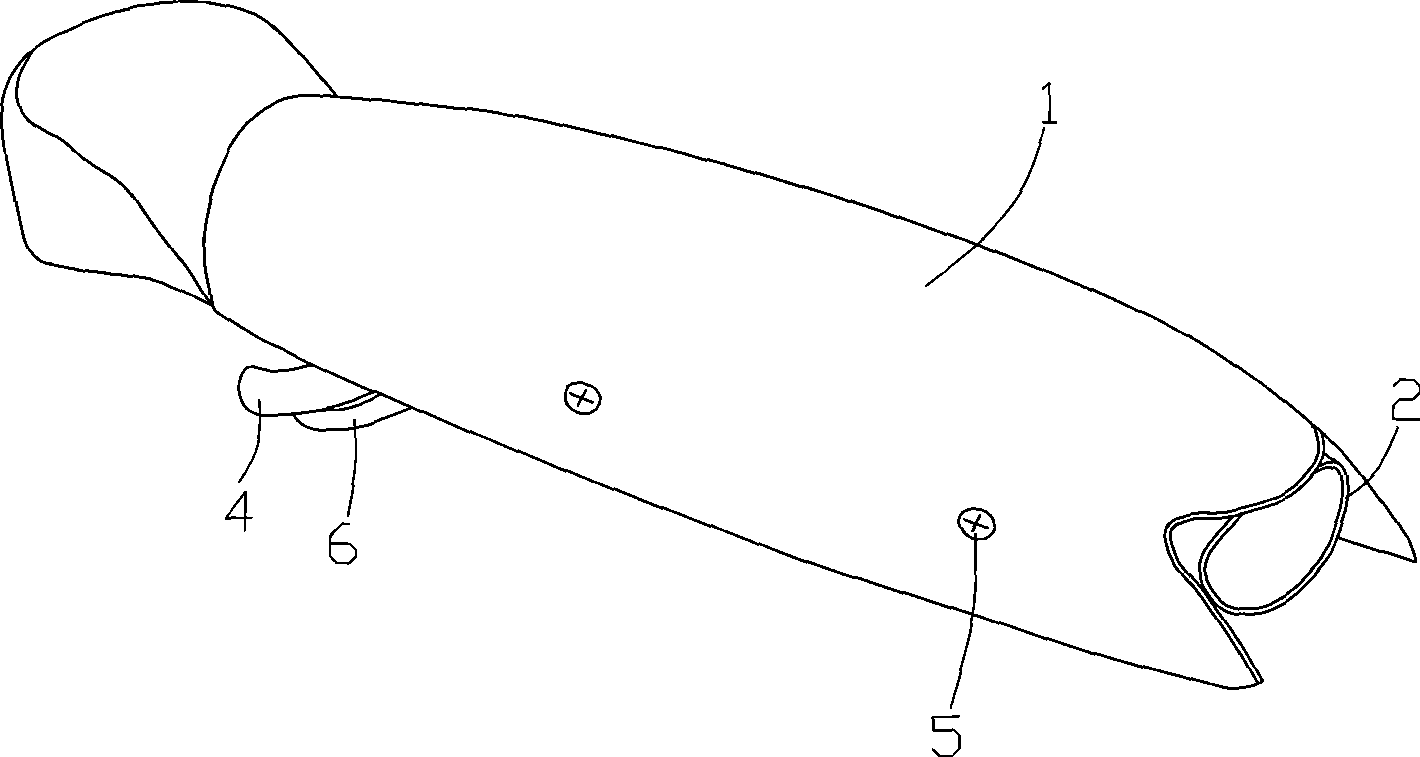

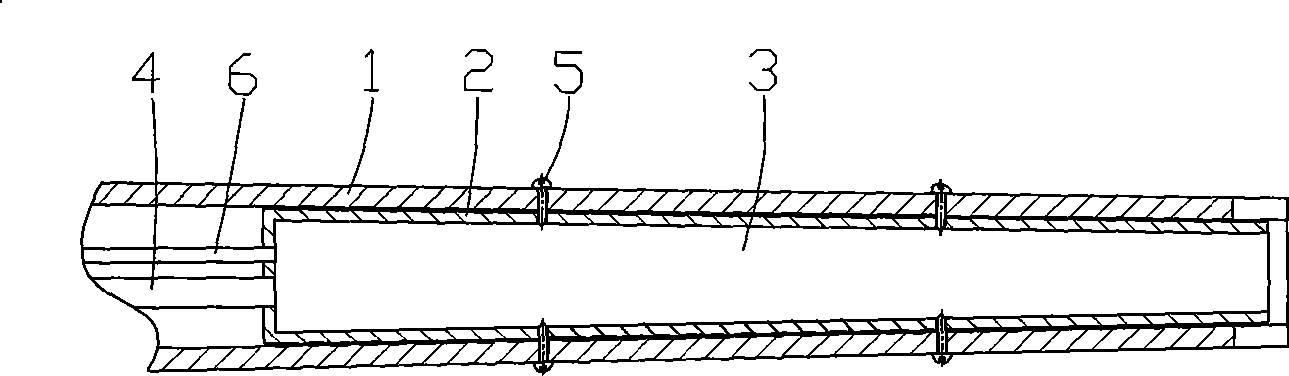

[0016] Example 1, such as figure 1 , Figure 2 and image 3 Shown, a kind of automobile wiper is made of parts such as support 1, air nozzle 2, air inlet pipe 4, screw 5 and water inlet pipe 6. Wherein the rear end of the bracket 1 is the installation part, which can be connected with the output shaft of the wiper motor (not shown in the figure). Driven by the wiper motor, the bracket 1 swings left and right with the wiper motor as the center; The remaining part is an elongated arc with the top of the arc on top. The air nozzle 2 is located in the support 1, and the air nozzle 2 is elongated and arranged in the same direction as the support 1. The two side walls of the air nozzle 2 are fixedly connected with the support 1 by screws 5.

[0017] from figure 1 , Figure 2 and image 3 It can be further seen that the air nozzle 2 is provided with an air flow channel 3 along its length direction, and the diameter of the air flow channel 3 gradually decreases from the back to the ...

Embodiment 2

[0018] Example 2, such as Figure 4 , Figure 5 As shown, in this embodiment, two airflow passages 3 are arranged side by side along its length direction on the air nozzle 2, and each airflow passage 3 is equipped with an air inlet pipe 4 and a water inlet pipe 6. The rest of the structure and implementation of this embodiment Example 1 is the same.

[0019] After the present invention is installed on the automobile in place, the front port of the airflow passage 3 is inclined upwards, and there is a certain angle between the center line of the airflow passage 3 and the windshield; an air pump and a water spray pump are installed at suitable positions on the automobile, The air pump supplies air to the intake pipe 4, and the water jet pump supplies water to the water intake pipe 6. Start the switch of the wiper motor, the bracket 1 swings left and right with the wiper motor as the center, and at the same time turn on the air pump, the high-pressure gas enters the airflow cha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com