Isolated diaphragm of cement slurry densitometer and installation and replacement method

A technology for isolating diaphragm and cement slurry, which is applied to determine the specific gravity and other directions by using the flow characteristics of the fluid, which can solve the problems of difficult cleaning, cost reduction, and measurement error, and achieve the effects of easy installation and replacement, cost reduction, and damage prevention

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

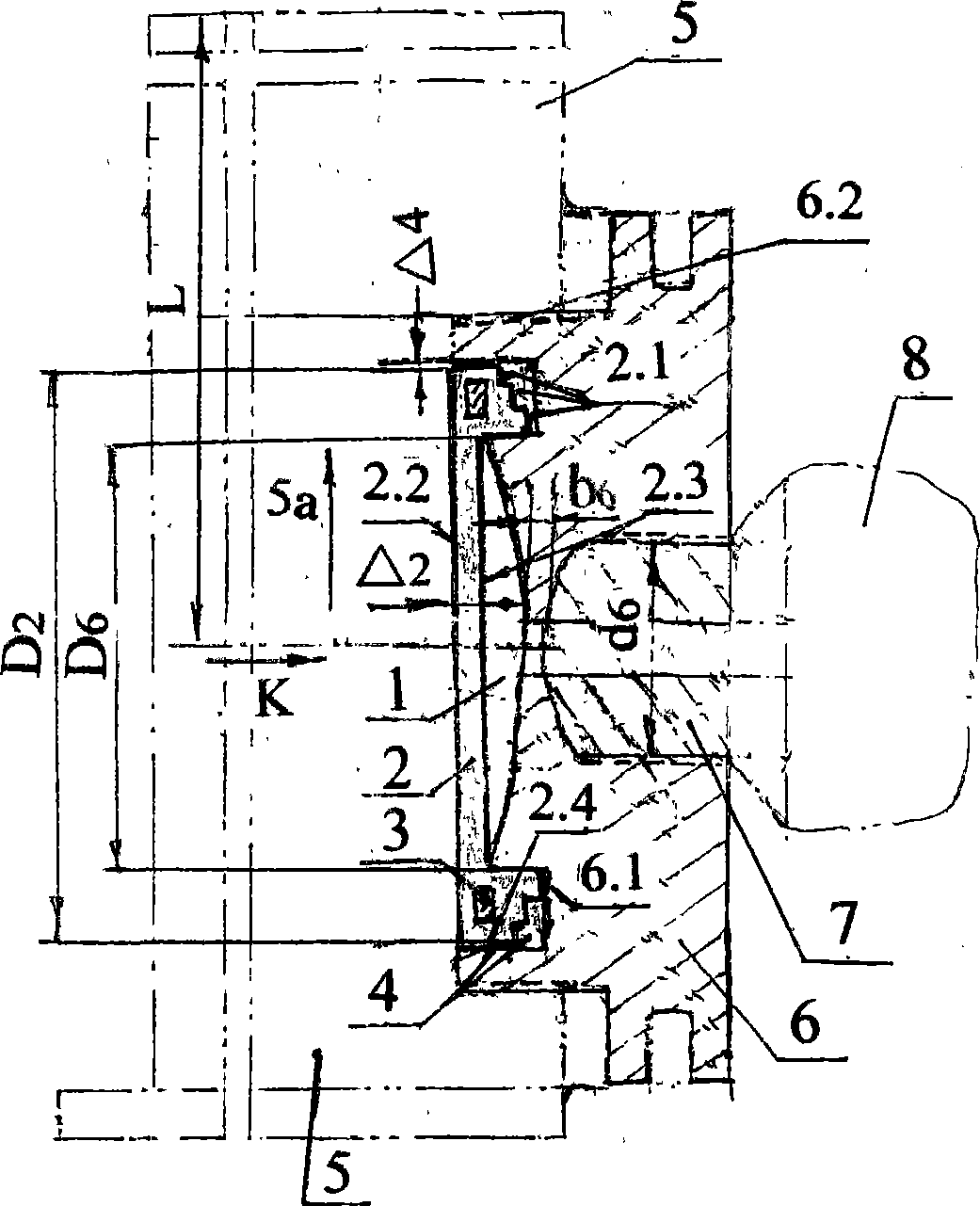

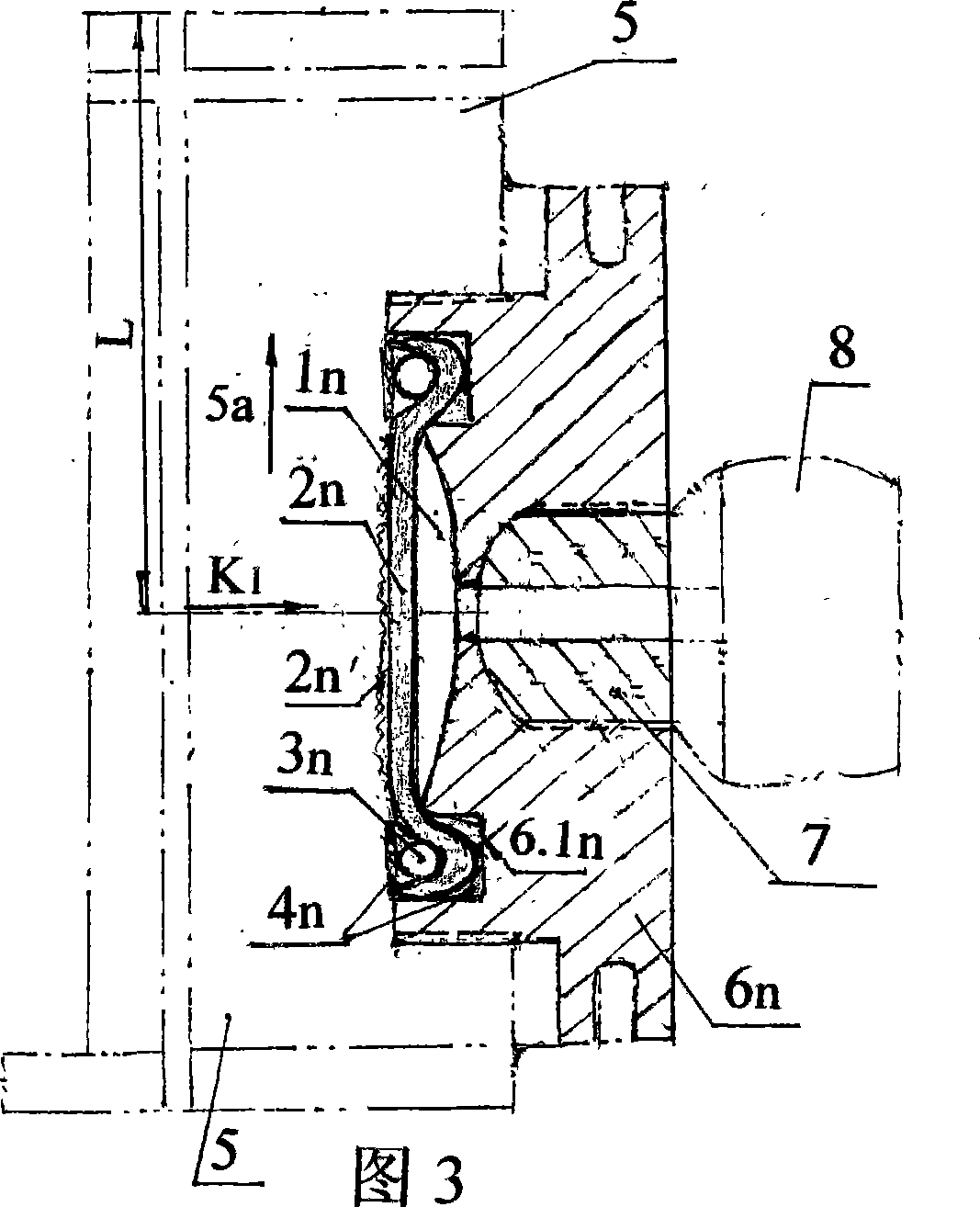

[0027] The cement slurry density meter putty separator of this embodiment is composed as follows:

[0028] See figure 1 , the inner cavity of the putty isolator 6 is provided with a cavity 1 filled with hydraulic oil for transmitting pressure, the front port of the cavity is opened with an annular groove 6.1, and a flexible isolation diaphragm 2 is installed inside, and the rear port of the cavity 1 is connected to the pressure gauge 8 The front end joint 7 of the pressure sensor is connected and transmits hydraulic pressure. The front port of the putty isolator has an external thread 6.2 for connecting with the measuring tube 5 . See figure 1 , the inner surface of cavity 1 is a circular table top, and the diameter of the large port at the front end is D 6 45mm, the rear small port diameter d 6 18mm, depth b 6 3mm.

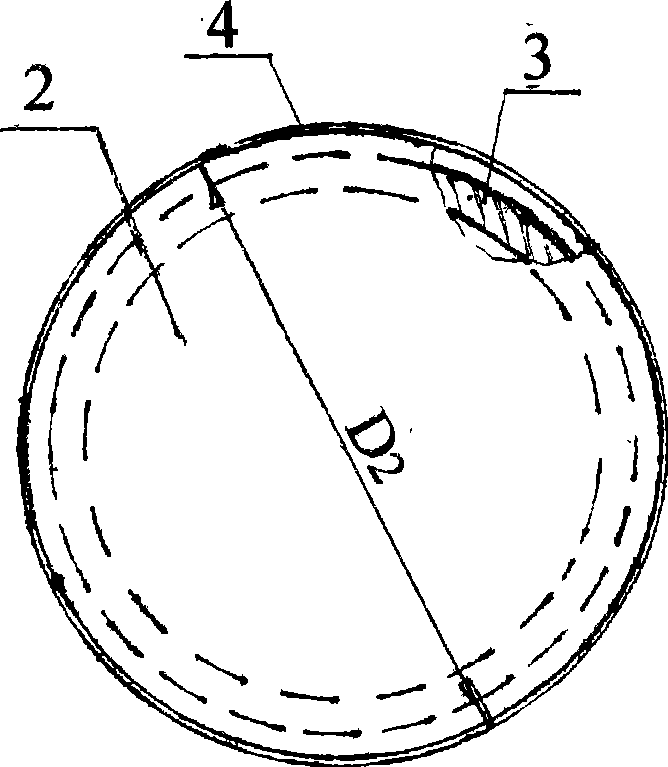

[0029] The isolation diaphragm of the present embodiment cement slurry density meter is composed as follows:

[0030] See figure 1 , figure 2 The fl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com