Microwave continuous graphite expansion apparatus

A technology of puffing device and microwave, applied in the field of microwave continuous graphite puffing device, can solve the problems that materials cannot continuously enter and exit the microwave heater, the L-shaped reflector and the furnace body collide with the building, the L-shaped reflector is troublesome to load and unload, etc., and the structure is simple. , The effect of low equipment cost and reliable operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described below in conjunction with accompanying drawing and specific embodiment:

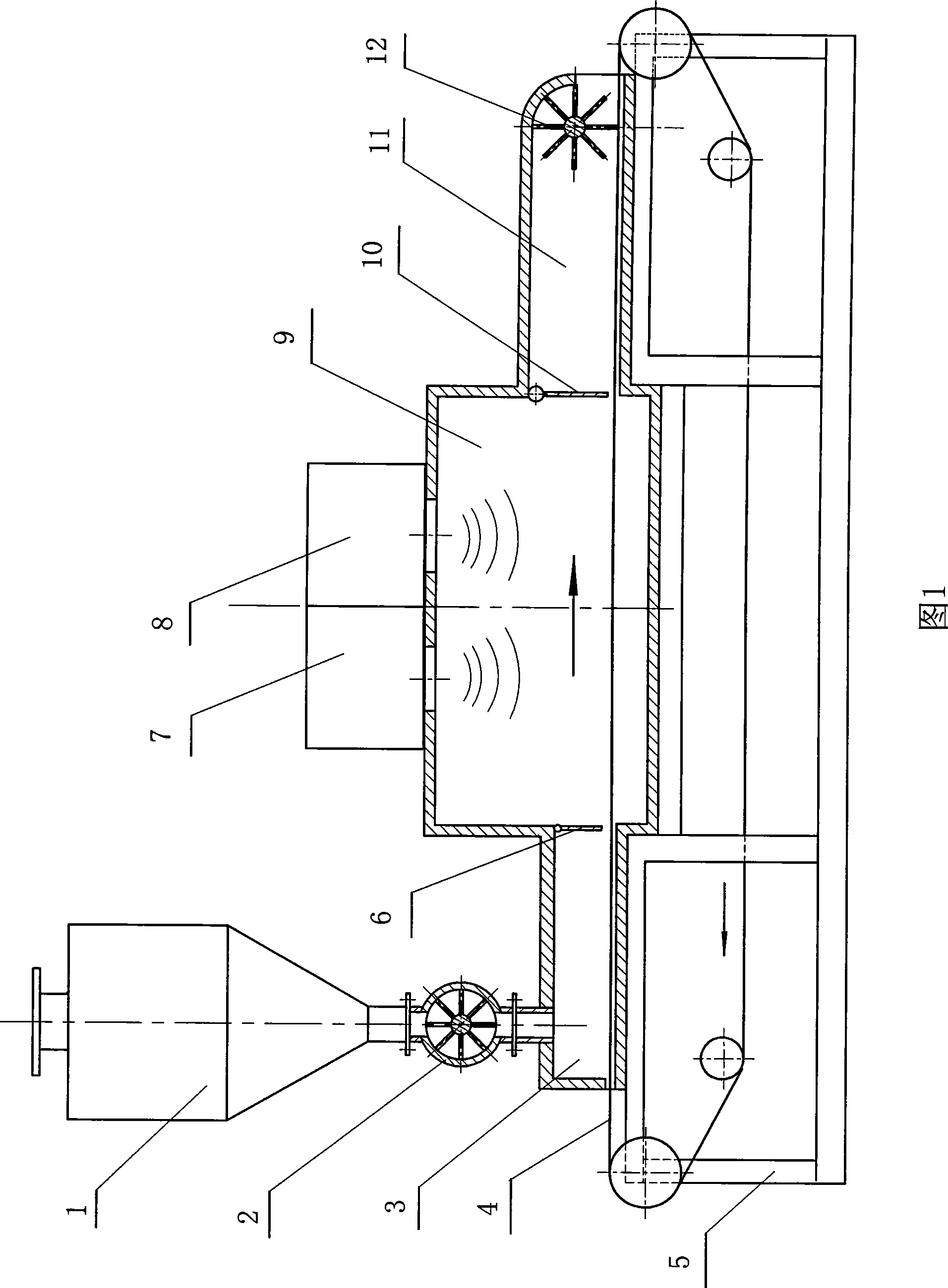

[0023] The microwave graphite continuous heating puffing device of the present invention is shown in Fig. 1, comprises: graphite hopper 1, rotary feeder 2, microwave feed absorption chamber 3, belt conveyer 4, bracket 5, feed absorption chamber microwave reflection plate 6, left Microwave generator 7, right microwave generator 8, microwave heating puffing chamber 9, microwave reflection plate 10 of discharge absorption chamber, discharge absorption chamber 11, rotary discharger 12 and other parts.

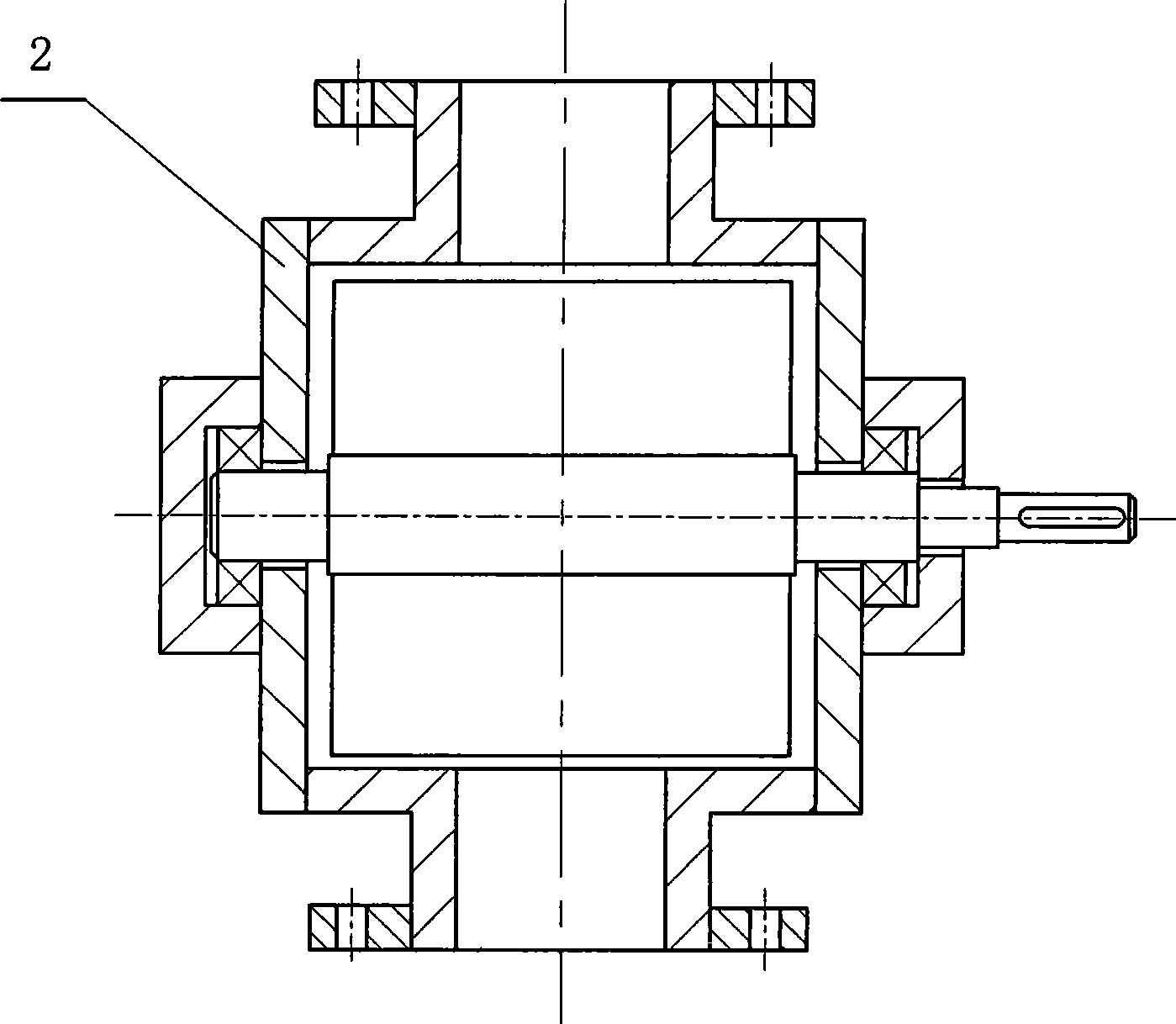

[0024] Microwave continuous graphite expansion device of the present invention, as shown in Figure 1, figure 2 As shown, it includes: a hopper 1, the bottom of the hopper 1 is connected with a rotary feeder 2, the upper and lower ends of the shell of the rotary feeder 2 are respectively provided with a feed inlet and a discharge port, and the center of th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com