Spherical surface hole boring and milling mechanism

A technology of boring, milling and inner hole, applied in milling machine equipment, boring/drilling device, details of milling machine equipment, etc., can solve the problems of product processing efficiency and quality reduction, spherical contour error, product cost increase, etc., to save equipment investment cost , The effect of reducing spherical contour error and improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

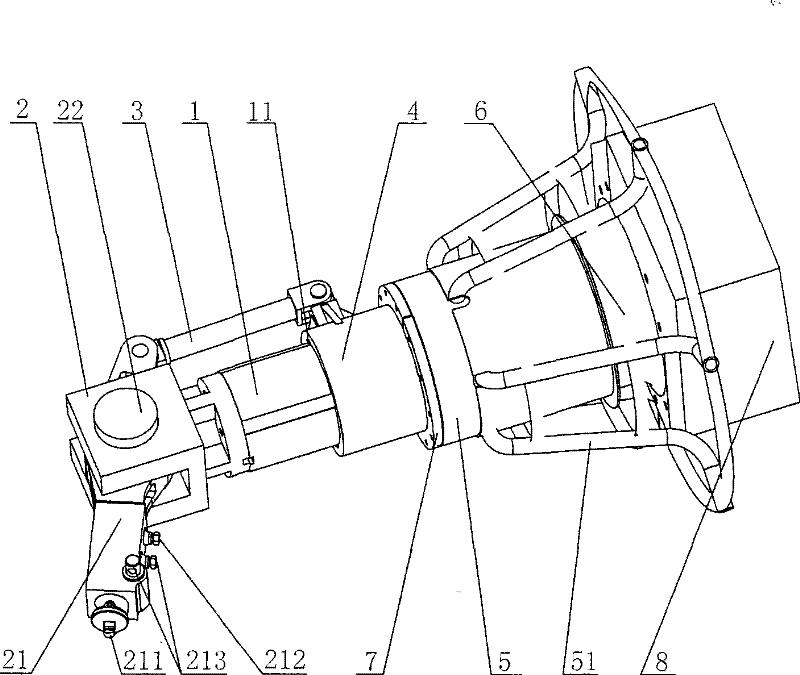

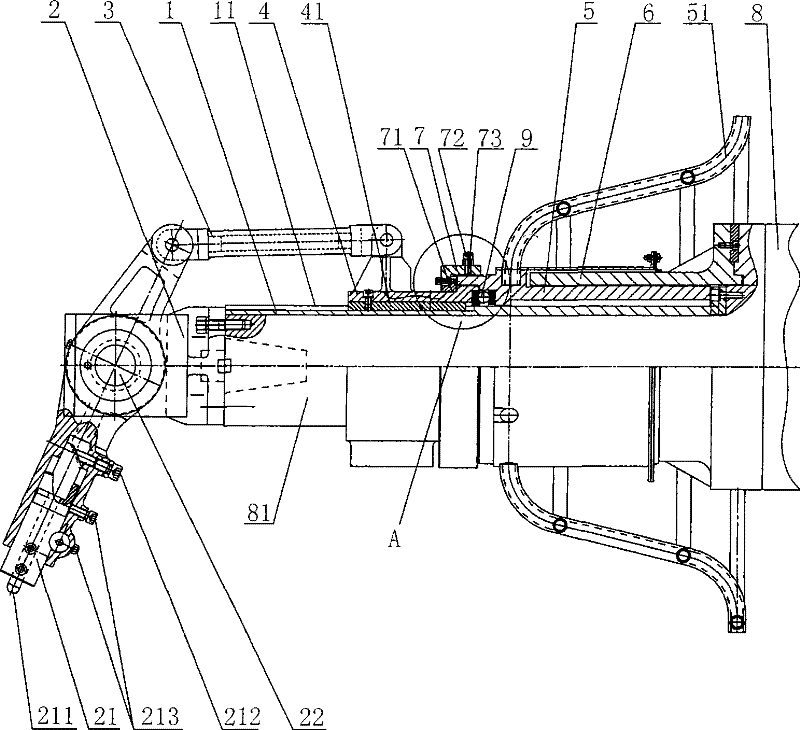

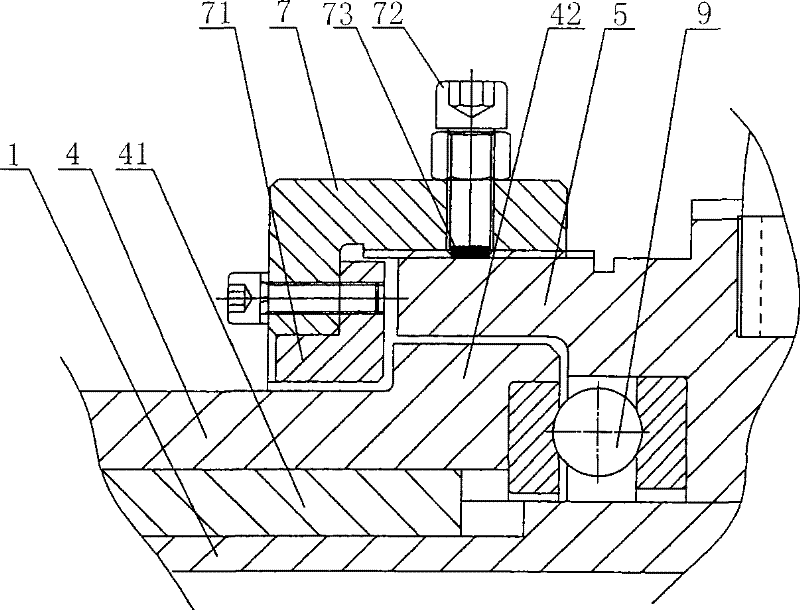

[0018] Such as figure 1 , figure 2 The spherical inner hole boring and milling mechanism of the present invention as shown includes a main shaft 81, the main shaft 81 is covered with a main shaft connecting sleeve 1, the front end of the main shaft 81 is provided with a tool holder disc 2, a tool holder 21 is installed in the tool holder disc 2, and a tool holder 21 is provided on the tool holder 21. The pin shaft 22 of the integral structure with the knife rest 21, the knife rest 21 is transferred on the knife rest disc 2, the knife 211 is installed at the front end of the knife rest 21 and is equipped with a cutter fine-tuning nut 212 and a cutter lock nut 213, and the cutter fine-tuning nut 212 tail The tail end of the tool is arranged as an inclined plane that cooperates with each other, the rotation of the tool fine-tuning nut 212 controls the expansion and contraction of the tool 211 , and the tool locking nut 213 is used to fix the tool 211 . The tail end of the tool ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com