Production method of Anthony pig granule feedstuff

A production method and pellet technology, which is applied in the direction of feed, animal feed, animal feed, etc., can solve the problems of large loss of heat-sensitive raw materials such as vitamins, low daily weight gain during growth and development, and low digestion and absorption rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0010] The production method of the suckling pig pellets in this embodiment includes two granulations, the temperature of the first granulation is 90°C, the temperature of the second granulation is 50°C, and other granulation steps are the same as the existing granulation. method. The main raw materials for the first granulation are: 570 parts of corn, 150 parts of wheat, 30 parts of soybean oil, 100 parts of puffed soybeans, and 150 parts of peeled soybean meal. The product of the first granulation is the basic feed for suckling pigs.

[0011] The raw materials for the second granulation include: 720 parts of the product after the first granulation (suckling pig base material), 100 parts of corn, 100 parts of wheat, and 80 parts of dehulled soybean meal.

Embodiment 2

[0013] The production method of the pelleted feed for suckling pigs in this embodiment includes two granulations, the temperature of the first granulation is 95°C, and the temperature of the second granulation is 65°C. Among them, the main raw materials for the first granulation are: 640 parts of corn, 120 parts of wheat, 20 parts of soybean oil, 80 parts of puffed soybeans, and 140 parts of peeled soybean meal. The product of the first granulation is the basic feed for suckling pigs. The raw materials for the second granulation include: 750 parts of the product after the first granulation (suckling pig basic material), 70 parts of corn, 50 parts of wheat, 60 parts of peeled soybean meal, 20 parts of intestinal Taikang, 8 parts of fine stone powder, 17 parts of calcium hydrogen phosphate, 2 parts of lysine, 3 parts of zinc oxide, 20 parts of 2% suckling pig premix.

Embodiment 3

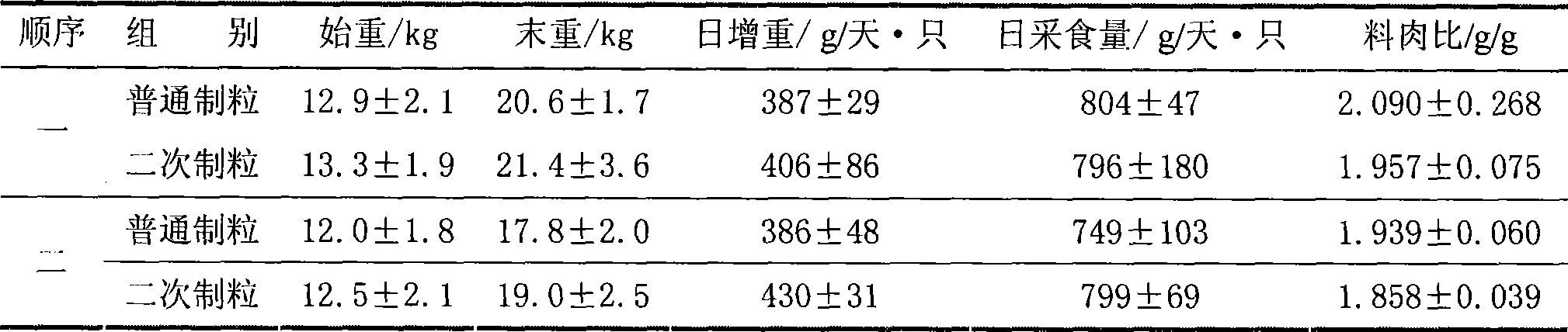

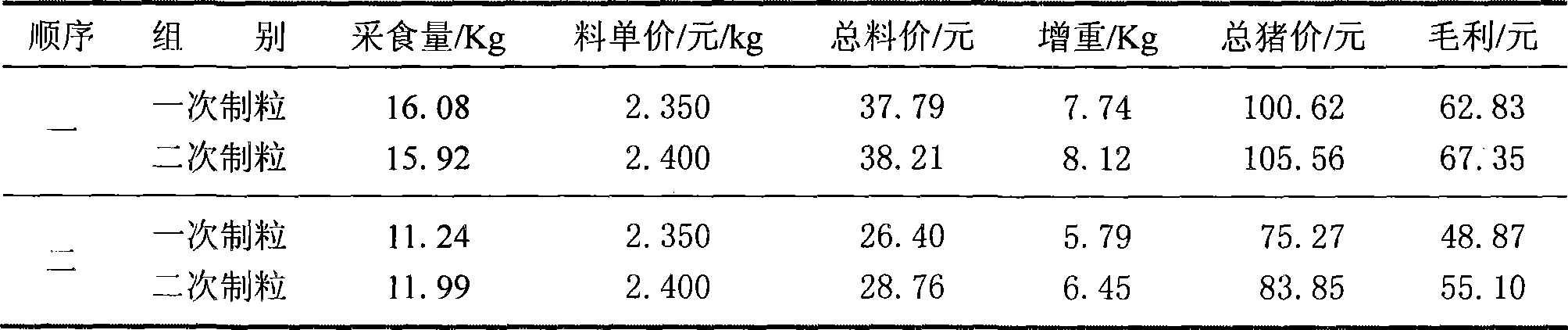

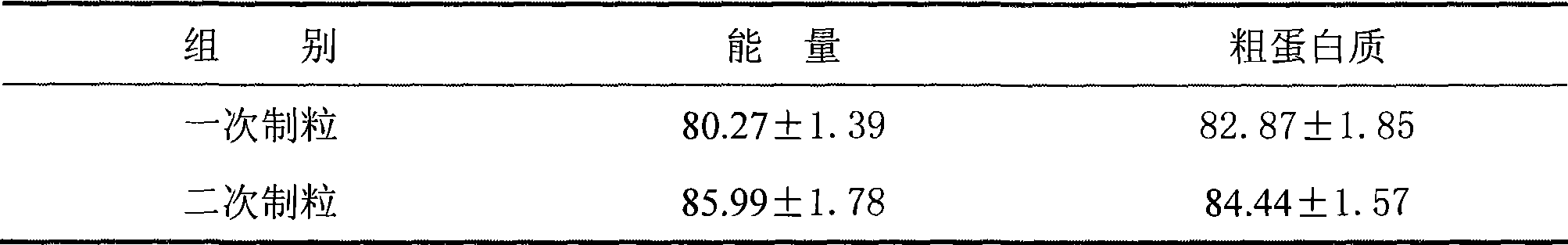

[0015] In order to verify the use effect of the suckling pig pellets produced by the method of the present invention, under the same formula, the impact of the common pelleting process and the secondary pelleting process on the production performance of weaned piglets and feed digestibility is as follows :

[0016] Formula for the first granulation (basic feed for suckling pigs)

[0017] raw material corn wheat soybean oil puffed soybeans dehulled soybean meal total Dosage 680 100 20 100 100 1000

[0018] feed formula

[0019] raw material Ordinary granulation process Secondary granulation process first grade corn 557 81 wheat 150 80 Secondary Soybean Oil 14 puffed soybeans 70 Basic feed for suckling pigs 700 Medium protein soybean meal 135 65 Intestinal Taikang 30 30 fine stone powder 5 5 Calcium hydrogen phosphate 15.2 15.2 Lysine 1.8 1.8 Zinc oxide...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com